RED DEER, Alta. — Through the spring and summer of 2018, curious drivers stopped almost daily to investigate the high steel pole and trellis structures set up alongside the road in central Alberta.

“Some people thought we were setting up a bird sanctuary.… They were waiting to see the nets. Other people thought it was for cannabis, but most had no idea,” said Jaclyn Smith, who with her husband, Colin, and children Maya, 12, and Aspen, 8, grows hops, a staple ingredient in beer.

The inquiries over the 5.8-metre-tall structures changed once the Smiths erected their Hard Hels Hops sign and the rows of trellis filled in with lush green creeping hops.

Read Also

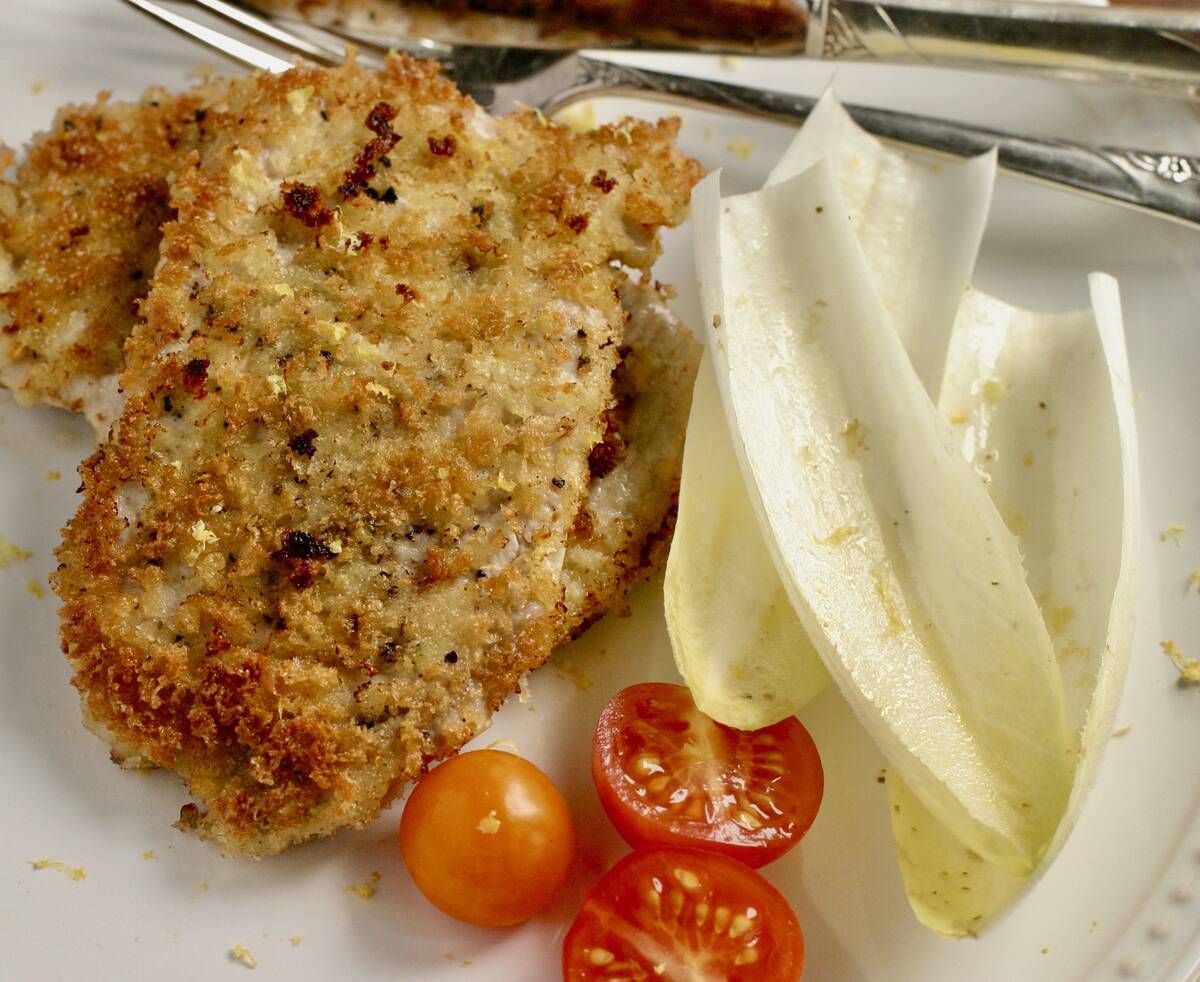

Nutritious pork packed with vitamins, essential minerals

Recipes for pork

“Lots of people don’t know what hops are or what they’re used for,” said Jaclyn. “We’ve given plenty of tours.”

The flowers, or cones, of the hop plant, Humulus lupulus, are used primarily as a bittering, flavouring, and stability agent in beer. Hops, which look like miniature artichokes, impart floral, fruity, or citrus flavours and aromas to beer and help it to retain its head of foam as well as stay fresher longer.

Smith said the yellow powder called lupulin inside each cone contains the hops’ acids and oils that brewers are looking for.

The farm name pays homage to her grandparents Harold and Helen Steele, who started their married life on a quarter-section across the road from Hard Hels Hops in the early 1950s, and where Jaclyn’s parents live now. The Smith’s acreage and hopyard take up 10 acres of another quarter that her parents also farm. Colin’s background is agricultural as well, from the nearby Pine Lake area.

The couple started into hops quite by accident. Jaclyn had been searching online for a fast growing perennial to shade her garden lettuce and spinach in an effort to stop it from bolting.

“I stumbled across hops … and asked Colin to build me a trellis. So then he was researching, and came across an article that talked about the demands for local ingredients for craft beer.”

As beer lovers themselves and self-professed dreamers, the seed of an idea began to sprout.

“In the beginning we didn’t know if hops would even grow here,” said Colin.

After research and discussions, which included seeking advice from other hops growers and support from local brewers, the Smiths moved forward.

“We put in our first plants in spring 2018,” said Colin. “It turns out they grow amazingly well.”

That initial half acre was increased by another full acre in 2019 with sales to local home and commercial brewers and a nearby maltster. The Smiths are in talks with additional Alberta breweries.

“It’s a way to get into the craft beer industry without a big investment,” said Colin.

The timing was right for the Smiths to try something new. The Smiths’ oilfield trucking company was a casualty of the oil patch collapse and Alberta’s economic downturn.

Currently, Jaclyn and Colin both hold outside jobs. Colin’s been helping his brother with harvest and Jaclyn’s employed at a local brewery.

Hops farming requires extensive labour. Work begins in the spring with hand-tying coconut rope to the trellis, followed by the manual training of the emerging hop bines to creep vertically up the rope.

Interestingly, the bines naturally grow only clockwise.

“One plant produces dozens of bines,” said Jaclyn. “We keep the best three to train to grow up around the rope.”

She said that at times the plants grow exceedingly quickly; up to a foot in 24 hours during the long hot summer days.

“We can watch our beer grow,” Colin said with a laugh.

Hop plants take three years to establish a mature root system, after which it directs more energy to the cone. Shoots emerge annually from the rootstock for 40 years or more.

Good drainage is important.

“Hops love water but don’t like to be wet,” Colin said.

The frequent rain of this past summer was welcome. For times when the skies remain clear, the plants are watered with an irrigation system.

An unfortunate side effect of moisture can be downy mildew, a pathogen common to hops. Treatment depends on severity.

“We use as little chemicals as possible but may resort to that,” said Colin.

Aphids can also be a problem at times. The Smiths combat those pests with ladybugs.

At harvest, the Smiths use a reach truck, said Colin.

“Someone at the top uses a machete to cut the plant.”

Another person cuts the bine off near the bottom. The lengths of bine are laid out on a flat deck and then run through a hops harvester. The machine’s fingers rake off the cones.

The Smiths borrowed a hops harvester this year but they have also done the job manually in the past.

“We’re lucky to have lots of family and friends to call on,” said Jaclyn.

That includes Maya and Aspen.

“They help us with everything we do here,” she said.

The Smiths invested in a pelletizer this fall.

“It’s one of only a very few in Alberta,” said Colin. “We can do custom pelletizing for other hops producers.”

Hard Hels Hops added a level of excitement before this year’s harvest by hosting its first Hopfest. Local musicians performed to a sold-out crowd in a large open space within the hopyard. Local breweries and a food truck were set up on site.

Colin said Alberta Health Services gave its thumbs’ up to the event, and he said COVID-19 physical distancing requirements were followed.

“Everyone followed the rules. Everyone was respectful,” he said.

“It was perfect.”