The story of super single tires for highway haulers has gone up and down. They gained popularity when first introduced because they cut fuel consumption by as much as three percent.

But the new technology had some problems, the main one being that the semi-truck went down when a tire blew.

A driver recently made the following statement on a trucking magazine website, “I went for a ride in a single-shod truck, the same model as mine, and was quite impressed with the soft ride. I especially liked the fact that with the wider tires, the truck didn’t fall into road ruts.”

Read Also

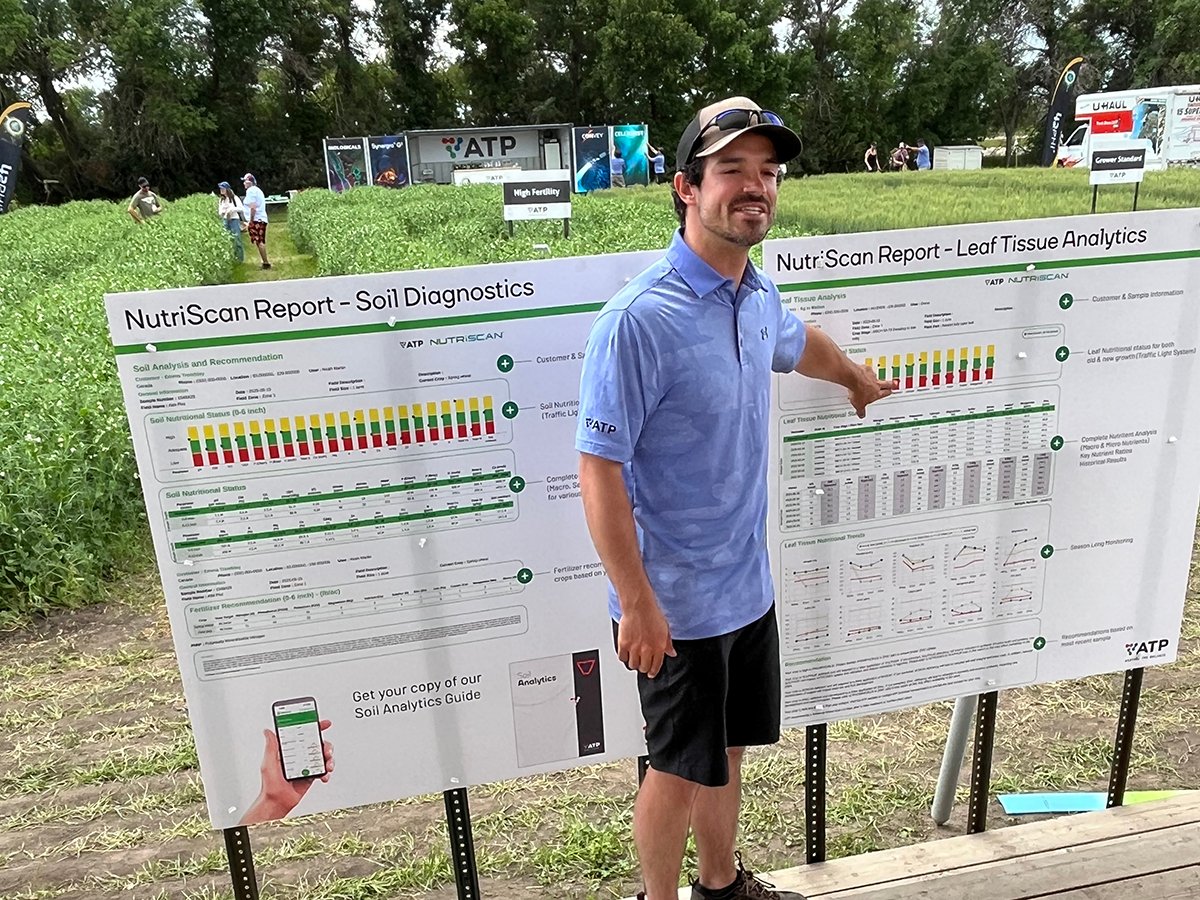

Granular biostimulant finds fit with fertilizer

ATP Nutrition recently unveiled its new Synergro G3 as the first solid, granular biostimulant derived from a consortium of biological metabolites.

Retired Kindersley Transport drive David Schritt said he tried super singles when the company bought some used equipment already shod with them. He said they tended to plow in heavy snow instead of cutting through it like conventional tires.

“Chaining up was really problematic because they have such a wide bar across, so they didn’t fit as well and they shifted around too much,” said Schritt in a phone interview.

“The law says you have to chain up two tires on each side. That wasn’t so hard with conventional duals because you just chained the outer two tires. But with super singles, you’re still required to chain up two tires per side, but now you have to struggle with that wide surface putting on your triples. That’s the chains that would normally go over both drivers. It’s a pain in the ass. Usually, it’s a blizzard and cold and cars and trucks passing close by.

“Guys found that if they had a flat on the trailer, they had to use the come-along and chain up that side of the axle and limp to the next town. Usually, you were out of luck finding a replacement.”

He also said they’re bad on ice because there aren’t enough edges and they really shouldn’t be used in the mountains. However, they are common on straight Interstate highways in the southwestern United States.

Tolv Pinckney runs a fleet of over-the-road rigs, plus four hydravac trucks in the Bakken oil fields in western North Dakota, an area hard on people, trucks and tires. In a phone interview, he said all the tractors have super singles on the steers.

“These hydravacs are so heavy, we’ve never had any trouble with pushing snow. But they don’t wear well when they’re on the steering end,” said Pinckney. Some operators say they get better life out of super singles on steers by rotating them. Pinckney said that idea is so far removed from conventional thought that he won’t even consider it.

“The way things are lately with COVID, I can’t be picky about brand. We buy whatever we can get. I don’t like paying US$800 a tire for steers and not get the brand I want.”

Kal Tire representative Colin Rafferty said super singles were designed for Interstate highways. They originally enjoyed a four percent fuel savings over conventional tires due to less rolling resistance. Because of improvements in conventional dual tires, that margin has narrowed to about one percent, but the higher price remains.

“The benefit in weight savings is still there. Super singles shave off about 200 pounds per axle. You have one rim instead of two, two sidewalls instead of four,” said Rafferty. “If you’re a bulk carrier hauling concentrated amounts of weight, super singles give you an advantage. That’s where that 200-pound saving per axle starts to pay off.

“In Canada, when super singles came out, they were only allowed to carry the maximum weight allowed in the States, and that was actually a reduction in your payload.

“Availability is the other factor in Canada. It’s a non-standard product, so most tire dealers don’t always keep inventory. There’s no advantage in terms of cost. One super single costs about double what a pair of conventionals cost.”

Nor is there a capacity advantage. Rafferty said two standard duals are actually rated to carry more than a super single, but the point is moot since carrying capacity is not determined by the tires but by provincial regulations. Whether fitted conventionally or with super singles, the same maximum weight per axle regulations apply — and this is less than either setup is actually capable of carrying.

Rafferty said a service call out on the TransCanada could conceivably cost $1,000 or more depending on mileage involved. He said Kal Tire concentrates their super single inventory at dealers along the TransCanada coast to coast. They don’t carry much inventory off that main thoroughfare.

“Retreading super singles is another issue. Our re-treading plants reject about half the super single casings we get in. The reason is that highways are rutted. The wide single tread is about 18 inches wide, so the tire doesn’t sit flat. It waves around, causing the belt package to shift, and that ruins the casing.”

Trapper’s Transport maintenance foreman John Grobbner said availability has prevented Trapper’s from trying super singles. He said Trapper’s operates mainly in Canada where super singles are not as readily available as in the States.

“With conventional tire setups, you can blow a tire and take it off and limp to the next town where you can buy the exact replacement size. You can’t do that with super singles.”