SALFORD, Ont. — One of the world’s largest air seeder carts is mixing the liquid with the dry.

In its all-dry configuration, Salford’s new AC4000 is a five tank, 945 bushel air seeder unit, including a 65 bushel small seed or product bin.

It joins large, single cart systems, including Seed Hawk’s 800 bushel unit and its 1,300 bu. prototype, the Bourgault 7950 at 950 bu., New Holland’s Flexi-Coil P4950 at 950 bu. and SeedMaster’s 780 bu. Nova.

The world’s largest production unit is the Horsch Anderson Seed Wagon at 1,000 bu.

Read Also

Growing garlic by the thousands in Manitoba

Grower holds a planting party day every fall as a crowd gathers to help put 28,000 plants, and sometimes more, into theground

When Salford started producing air seeding equipment about eight years ago, the company wanted to take advantage of its poly tanks, which were marketed in both liquid and dry fertilizer configurations.

“Not every farmer wants to use dry products (such as urea) exclusively with their air seeder. Most importantly, for larger operators who choose liquid products, we felt they shouldn’t have to haul a second cart to do it,” said Brad Baker of Salford during the unveiling of its new extra large air seeder cart.

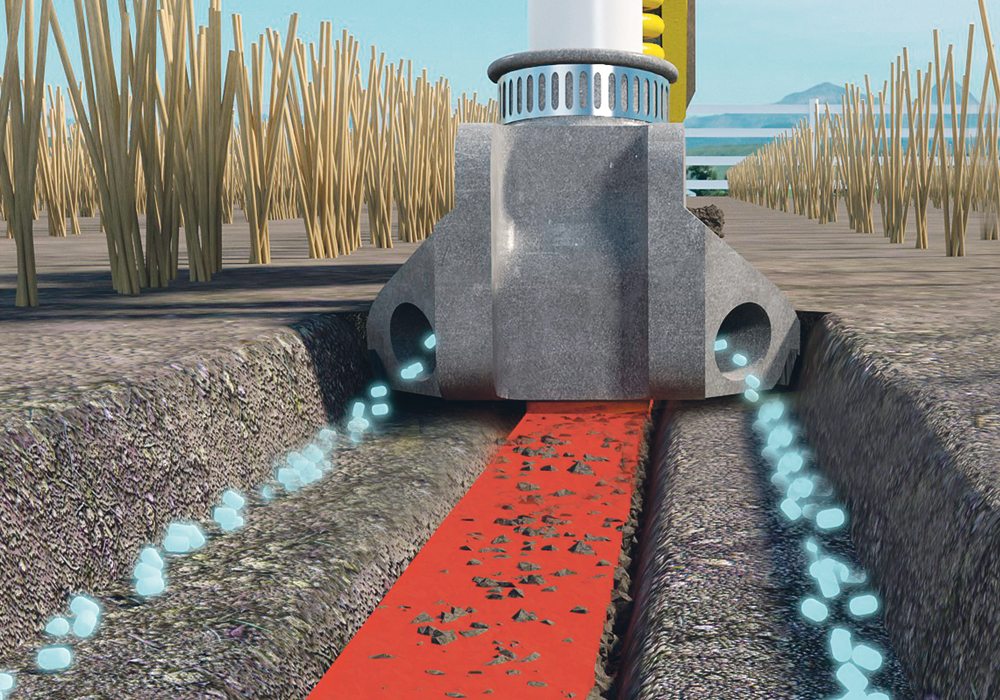

As a result, the AC4000 has a three compartment dry product component of 550 bushels and a 4,000 gallon liquid tank.

The company unveiled the configuration May 21 at its Salford, Ont., factory two hours west of Toronto.

The cart uses the same stainless steel dry metering components used on its smaller models. It retains the Swift Current, Sask., built REM fans and a Pentair Hypro 9303 pump. The air runs are split 10 ways.

A Winkler Man., built Convey-All 10-inch conveyor, running a 16-inch belt, lifts the dry products to the tanks at 67 bu. per minute. The loader is mounted to a remote-controlled hydraulic arm. A 10-inch auger is available as an option in place of the conveyor.

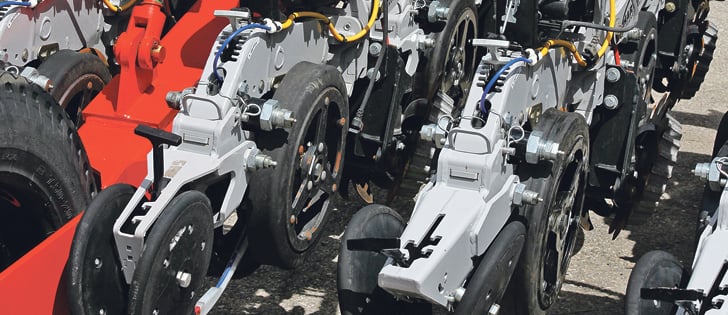

Pegged poly, stainless or fluted, metering rollers are available depending on the seed or product being used. Metering is hydraulically driven with variable rate and is compatible with ISO displays.

The big liquid tank is available with an optional ground drive metering system.

“We wanted to be as flexible as possible for farmers,” said Anson Boak of Salford.

Salford’s Mark VanVeen said not every farmer is using dry or liquid products as their first choice.

“It is often a logistics issue. Their local dealers might not have liquid or the farmer might not have storage or their cart might not handle it. And lots don’t want to pull that long a train of equipment over their fields or down the road, so a big liquid cart isn’t in the cards,” said VanVeen.

At 50 feet, Baker said the AC4000 isn’t the longest on the market.

“Loaded, about 110,000 pounds needs a lot of tire to prevent soil compaction. So we put it on (six) 900/50 R46s. That distributes the load,” he said.

The machine is expected to fill a growing market of large acreage operators in Western Canada, the American Great Plains states, Australia, Eastern Europe, Russia and western Asia.

Salford will build the units in Ontario with regional assembly in Russia. The company operates plants in Iowa, Russia and Canada.

The company says pricing is aimed “below the comparably sized Bourgault” unit, meaning likely north of $350,000, but producers will have to contact the company for details.

For more information, contact Brad Baker at 1-866-442-1293.

Contact michael.raine@producer.com