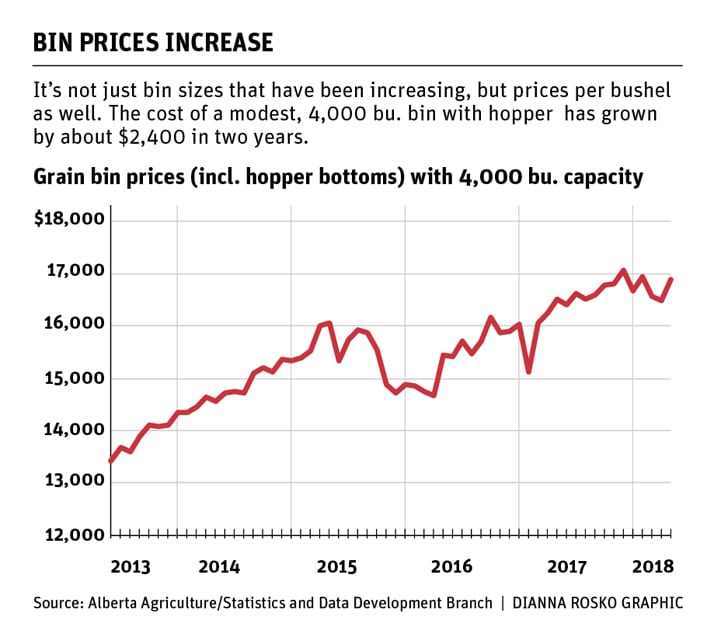

Grain bin manufacturers are getting crushed under the weight of rising steel prices and a recent development will only make matters worse.

Curtis Epp, operations manager with Darmani, a bin manufacturer in Fiske, Sask., said costs are up 25 to 50 percent year-over-year, depending on the type of steel.

That represents a significant escalation in expenses for a product where the raw material accounts for 70 percent of the total cost. Bins can require up to 16,000 kilograms of steel.

Epp said the company is doing everything it can to help mitigate mounting costs, such as operating 24/7 in an effort to keep costs down by driving production volumes up and by eliminating models that don’t pay.

Read Also

Urea prices heading higher: analyst

A fertilizer market analyst thinks urea prices have bottomed out and are heading higher through the first quarter of 2026.

But the reality is the spike in costs is resulting in reduced margins and a 10 to 15 percent increase in the prices farmers pay for their bins.

Epp said the one saving grace for Darmani is that the company deals directly with its farmer customers, bypassing the added expense of using dealers and distributors.

“I tell you what, we wouldn’t be producing right now, we’d be shut down,” he said.

Farmers haven’t felt the full impact of higher bin prices yet because manufacturers have been using steel bought at lower prices but that’s about to change.

“Everyone across the board will be out of every piece or speck of steel they ever booked and that’s when you’ll see the sticker shock,” said Epp.

He anticipated higher bin prices by mid-June.

Richard Walde, sales manager with JTL Industries, a bin manufacturer in Neilburg, Sask., estimated their steel costs are up 20 percent.

“They’re predicting more yet,” he said.

Steel prices have been bolstered by rising global demand for the product and tight supplies. But the biggest factor is a 25 percent tariff the United States has applied to imports from most countries.

The tariff went into effect on March 23 and will remain in force indefinitely. Canada, Mexico, the European Union and a few other countries were initially excluded from the tariff. But late last week the U.S. expanded the tariff to include those three nations, which is going to put more pressure on steel prices.

Walde said the rising steel costs are cutting into the bottom line.

“It bites into margins for sure,” he said.

All of our competitors are faced with the same situation. It is what it is.”

The company has had to increase its bin prices by about 10 percent and further hikes are on the horizon.

Walde said it has hurt bin sales but farmers are still buying.

“The phones are a little bit slower,” he said.

“The bottom line is you still need storage.”

Curtis Chapman, president of Canadian Tarpaulin Manufacturers, one of Canada’s largest grain bag distributors, doesn’t know if rising bin prices are forcing farmers to contemplate switching to grain bag storage.

“It’s hard to say what’s driving things. Our sales are certainly increasing but for us they’ve been increasing year-over-year for the past five years,” he said.

“It would certainly make sense that some producers are leaning more towards the use of grain bags as opposed to investing in the more expensive bins.”

Chapman was anticipating slower sales this spring due to the drought-reduced 2017 crop, but grain bags orders have been strong, which may have something to do with the rising cost of grain bins.

Epp said bin manufacturers are in “survival mode” as steel prices continue to rise with no end in sight.

“It’s not even done yet, (which) is the worst part,” he said.

“It doesn’t look pretty for the next six to eight months.”

But according to one analytics firm, relief could be around the corner.

IHS Markit expects steel prices to peak in the second quarter of 2018 at levels not seen since a spike in 2011. They will ease a bit in the third quarter as production increases and should stabilize by early 2019, although at “very expensive levels.”