The Groses have been inventing and building a variety of agricultural equipment on their farm near Clive, Alta., for the past 32 years

CLIVE, Alta. — There’s a lot going on at Rodono Industries Ltd., an agricultural equipment manufacturing business owned and operated by the Grose family.

Vehicles come and go from the yard site, located on Jim and Faye Grose’s grain farm near this central Alberta community. Within Rodono’s 20,000 sq. foot building, the front office phone rings frequently. On the manufacturing side the simultaneous whir and clang of motors and machinery compete with the necessary loud conversations. Machine shop smells from oils, coolants and grinding dust hang in the air. It’s a busy place.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Office manager Faye Grose and her husband, Jim, started the business 32 years ago.

“He’s a thinker,” she says, and he was always motivated to improve on safety, inefficiencies and shortcomings of original manufactured equipment.

She recalled the invention that launched Rodono in 1987.

“We patented a hydraulic feeder house reverser for a combine.”

The attachment addressed the common frustration of feeder house plugs.

Rodono manufactured the reversers until about 2005, by which time they became factory standard.

Another major design was a replacement straw chopper rotor for combines in the early 1990s.

“Then we had a fire in 2005,” says Faye. “We lost everything”.

The tragedy drew home Jim and Faye’s sons, Darren and Cory, who joined the company and over time, expanded Rodono’s services.

“The boys have brought the products along further,” says Faye.

Product development is done in house: the design, machining, laser cutting, fabricating and powder coating.

Darren, an agricultural engineer, works in design while Cory is the hydraulic specialist and runs the repair department. The brothers both provide product support. They live on their own farms in the area.

Their dad, the original idea guy, is currently focusing more on improvements to his farm. Faye says he’s also got some personal interest projects on the go: restoring cars and tractors.

It took a year for the company to rebuild after the fire and then start developing Jim’s next idea.

“My husband had in his mind this extending retracting auger,” says Faye. “We patented that in 2009 and have been making it ever since.”

She said that some of the big agricultural companies are licensed to sell Rodono’s XTend retracting auger.

The company’s newest product is its XTend retracting transfer conversion kit designed to work with air seeders to efficiently move grain from the hopper bottom B-trains, which are in common use today.

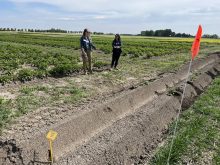

Product testing is done on site. It helps that the family actively farms about 1,600 acres in total, generally seeding canola, wheat and barley. Darren also runs a 20-head Angus cross cow-calf operation.

“Because we’re a functioning farm, we can test,” Darren says. “We can’t envision every set of circumstances out there but it’s a good start.”

Faye adds: “We’re small so we can adapt quickly. When someone calls with a problem, Darren can have it fixed the next morning.”

The company employs 10 people, outside of family, including millwrights, machinists, welders and assemblers.

Third generation Grose family members have grown up around the shop. Darren’s son, Aden, 18, just started the heavy equipment technician program at Olds College.

“He’ll likely stay in agriculture but not necessarily at Rodono, at least not right away. It’s important to get life experience,” says Faye.

Aden’s younger siblings help in the shop with shipping and cleaning.

Darren says there’s not many farm equipment manufacturers in Alberta, compared to Saskatchewan and Manitoba. He attributes the difference to Alberta’s higher labour costs.

Rodono Industries has no travelling sales person but regularly attends trade shows around the country. Faye says it’s her favourite part of the business. “I like talking with people”.

Her least enjoyable aspect of the job? The technology.

“When I get to heaven I hope there’s not a computer in sight,” she says.