BLACK DIAMOND, Alta. — A modern chicken farm is a high tech operation that still requires the human touch.

These farms run on cycles of eight weeks, in which newly hatched chicks weighing 50 grams are placed in warm barns and raised until they are 38 days old and weigh 2.5 kilograms. At that point, they are ready for the broiler market.

“We have done the eight week cycle 225 times,” said Reg Ference, who with his wife and business partner, Erna Ference, raise broilers at Foothills Poultry south of Black Diamond.

Read Also

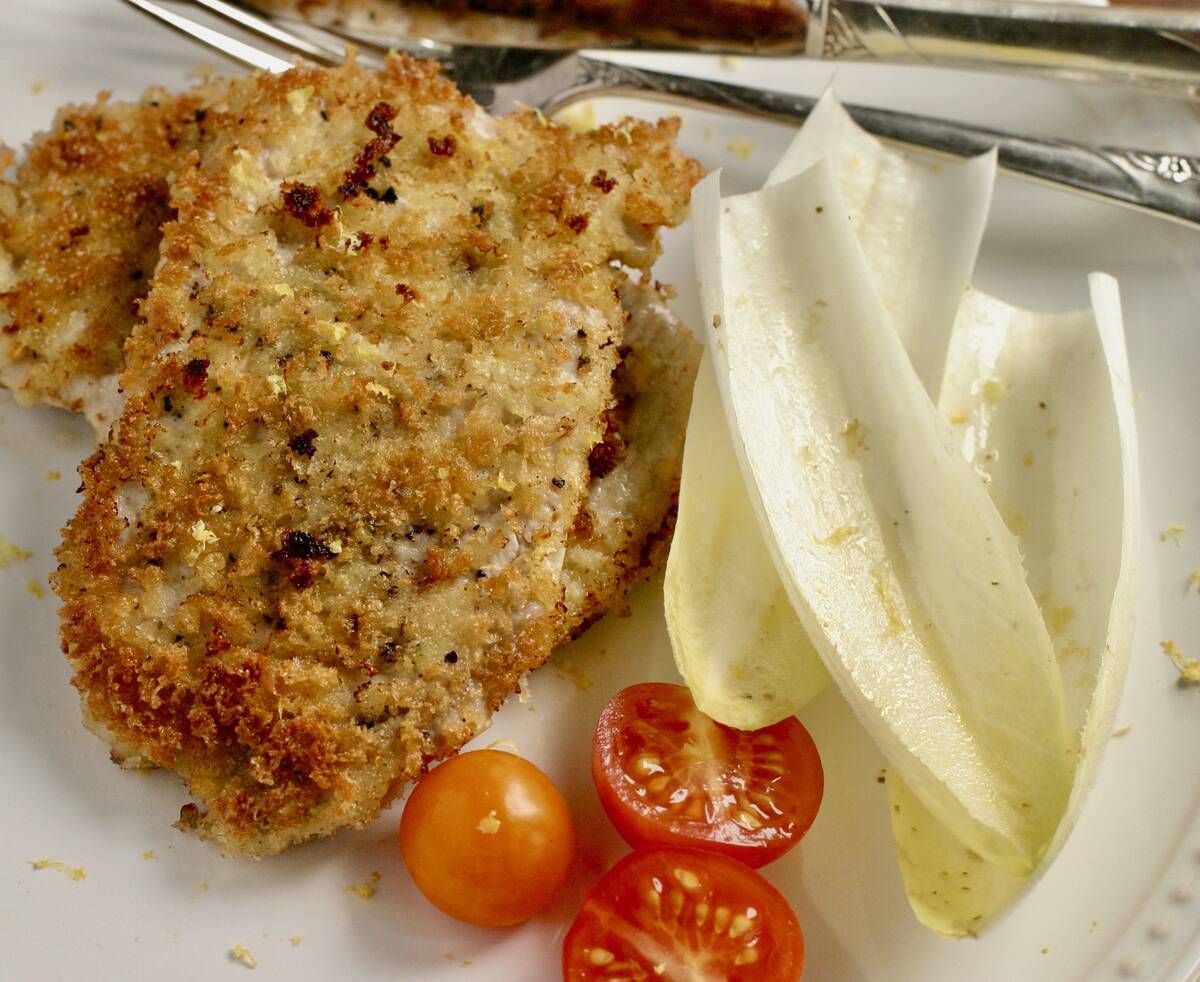

Nutritious pork packed with vitamins, essential minerals

Recipes for pork

Their five children, Trevor, Benjamin, Stephen, Andrea and Byron have been involved in the family operation over the years, and 25-year-old Byron is now poised to take over.

“All of the kids have participated. All of them know what the inside of a chicken barn looks like,” said Reg.

“We do have a passion for agriculture, especially the family farm,” Erna said while attending the Chicken Farmers of Canada annual meeting.

“Farming is a unique business, and I believe the economics and policy is treated differently. Supply management is important, and it allows us to do a lot in our business.”

She and Reg have served on the Alberta Chicken Producers board, and Erna is the current provincial chair.

Reg got involved with farm politics at a time when the chicken business was starting to lose money, and he feared he was going broke. He wanted to know what was going on and started to speak up at producer meetings.

Erna sat on the board from 2004-11 and also served on the Chicken Farmers of Canada board in various capacities, including the executive committee.

She returned in 2012 and was elected Alberta chair. Erna also sits on Alberta’s Workers’ Compensation Board.

“Hopefully we served the industry well,” said Reg, who also sat for six years on the Alberta marketing council, which oversees marketing boards and commissions in the province.

However, their first love is the farm.

They have capacity to raise more than 100,000 birds at a time. Every bird requires care 365 days a year. Computers monitor the barns with automated feed and watering systems, precise environmental controls and alarms in the event of an emergency.

Someone must always be there, monitoring the feed and water supplies or walking among the birds to check their well-being.

Farming was not Reg’s original plan, even though his family had homesteaded at Consort.

“I had no idea I would be a chicken farmer,” he said.

“When I finished SAIT (Southern Alberta Institute of Technology), Dad decided he was going to start a chicken farm.”

His father, who worked for Canadian Pacific Railway, bought the Black Diamond facility when he decided to farm full time. It had originally been a Lilydale corporate farm, which was then sold to the farmer-owned co-operative’s manager.

Eleven buildings were on the property when the Ference family took it over.

One barn is now left on the site, and a newer two-storey barn is located four kilometres from town.

Reg and Erna met when they both worked for Canadian Western Natural Gas in Calgary. Reg was a draftsman and Erna eventually obtained her certified management accountant certification.

They took over the farm and adapted to change, whether it was new computer technology or instituting a high level of biosecurity to keep out disease.

It was all hands on deck March 17 when more than 35,000 chicks arrived at the farm. They had been born early in the morning in Edmonton and shipped to the farm the same day. The chicks arrived in trays of 102 each, and the first priority was to get them into the heated barn and eating and drinking.

“You don’t want them stuck on the truck any longer than they have to be,” Byron said.

“We want to get them down and have water and food in their bellies.”

The chicks are fed a wheat-based diet, of which 85 percent has been finely ground and pelleted with added nutrients and then crumbled so the chicks can handle it.

The barn is heated to at least 30 C plus added humidity.

“They are attracted to really shiny things. If you have rings on your fingers, they’ll peck at them,” Byron said.

This farm has a full biosecurity program, in which visitors must sign in, change into special overalls and wear clean booties.

When the birds are sold, the barns are opened up to circulate fresh air and staff clean everything the birds contacted.

Chicken Farmers of Canada has also added a mandatory animal welfare component recently.

“As we have evolved, we have gotten better at providing a better environment for them,” said Reg.

Cold cathode lighting is used in the barns for the first 24 hours of the chicks’ lives so they can adjust to their new environment. The lights are adjusted a few hours at a time during the next few days to mimic dawn and dusk.

The Ferences also monitor carbon dioxide levels in the buildings be-cause stressed birds will exhale more CO2 during the first few days.

As well, the farm follows a maximum stocking density.

“If the birds aren’t doing well in the barn, maybe there are too many birds in the barn,” Reg said.

Producers must cut back on the number of birds in the barn if they cannot reach certain performance criteria, such as growth, mortality levels and condemnation rates.

“It is progress and it is what our consumers demand.”

Market-ready birds are shipped to Lilydale in Calgary, which is one of three federally inspected plants in Alberta.

Enhanced care also means more paperwork and management, which Reg and Erna are taking on.

Animal welfare auditing programs, on-farm food safety plans and temperature, humidity and carbon dioxide monitoring must all be documented daily. As well, the Canadian Food Inspection Agency is becoming more involved with bird transportation.

“People didn’t get into chicken farming to do paperwork. They want to be around livestock,” Reg said.

However, he accepts the new reality because it means better serving consumers, who often make chicken their first choice of meat.

“It’s a challenge for us, but it isn’t necessarily bad because you can always do a little better,” he said.

He has spent time with processors to learn what they want and strives to give them what the market demands.

“My goal is always to be in the top third of the industry,” he said.