Sometimes we become so immersed in our particular project or process that we don’t step back for a bird’s-eye view. Are we looking at trees or looking at forest?

That’s the situation many variable rate farmers are in, said Dennis Bulani in his video presentation to the recent 2021 Ag In Motion event.

As one of the pioneers of variable rate agronomy on the Prairies, Bulani is recognized as having produced some of the most up-to-date research on soil fertility over the past 25 years.

Read Also

Growing garlic by the thousands in Manitoba

Grower holds a planting party day every fall as a crowd gathers to help put 28,000 plants, and sometimes more, into theground

Bulani owns Rack Petroleum with more than a dozen dealers in Saskatchewan, out of which grew Bulani Agro and the Ultimate Yield Management Institute (UYMI).

His presentation is titled variable rate and precision ag: think about your thinking. It’s available on-line until the end of the year. In it, he discusses what he’s learned about zone management, his successes and his mistakes. He provides a realistic assessment of the opportunities and obstacles of implementing variable rate agronomy.

Bulani is frank about the failures he’s encountered in exploring the VR concept. He begins by putting the kibosh on competition between mapmakers and their high tech products.

“All too often when growers are deciding who can help them implement VR, the conversation turns to why they should spend money on your maps and why are they better than the other guy’s maps. All maps layers, regardless of methodology, are a layer of useful information regardless of how they were created,” emphasizes Bulani.

“Maps should complement good agronomy, not substitute for bad agronomy. The goal is to ensure that every plant has sufficient water, nutrition and soil structure, with good management to sustain it. None of these parameters should limit plant health and crop yield. Soil and precision ag is just one small piece of an overall good agronomy plan.”

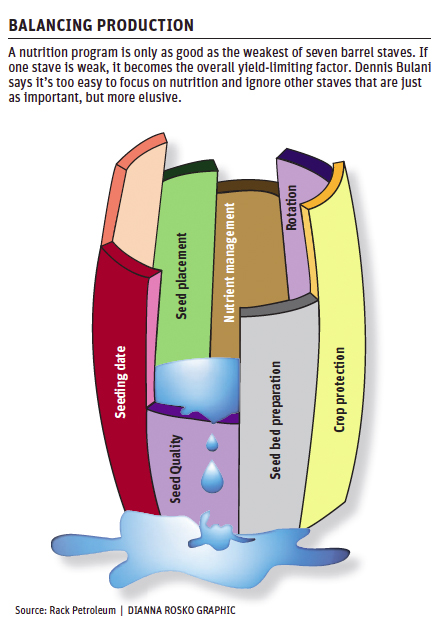

Bulani reviewed Liebig’s Law of the Minimum barrel drawing, adding that the barrel is like a chain that’s only as strong as the weakest link.

On the Prairies, if you have good moisture, then you cannot use moisture as the weakest link. You have to look at all the other factors to find the barrel stave that’s not doing its job. He adds that there are at least a half-dozen methods for putting together a workable VR system.

VR crop varieties — “Something that growers should think about is variable rate with seed varieties and seed densities. With the wide variety of great genetics in each of the crops we grow, and the delivery systems we have, you can pick genetics to match the micro-climate of each zone in a field.

“You can maximize your returns on a field by seeding different varieties, such as a longer season variety on the hills and higher yielding variety in the valleys. I tried that way back in 1996 before we had the delivery systems we have today. I converted a Morris air drill to put in three varieties.”

He put Columbus on the hills. That’s a longer season wheat known to be drought-tolerant. He put Katepwa hard spring wheat known for rust resistance on the yellow and lime green areas of the map. It’s higher yielding and it’s a good match for the slopes. Then on the dark green zones he seeded a bearded variety called Laura, which was the highest yielding variety back then.

“When the crops emerged and you could see all these different varieties scattered all over the field, needless to say, my neighbours thought I had lost my mind. It looked like it would be a good experiment, but then the field got hailed out, so we didn’t learn anything.

“Think about seed costs. Why would you put a 900 dollar bag of canola seed on a red zone where you know already the soil will only grow a 30 or 40 bushel crop? Put on a lower-cost variety that matches the potential of the zone. That’s how you get the best (return on investment) on your seed investment.

“Our ultimate goal is to have every area of the field yield the maximum. When we look at a variability map, ideally, we want to get every area yielding the same by modifying the nutrient and water-holding capability.”

Topographical grid analysis — In 2001 Bulani launched a project to soil test and map individual fields on a two-acre basis in an attempt to extract as much information as possible. The two-acre topo-grid may never be practical for the entire prairie landscape, but Bultani did get a firm grasp on the importance of elevation in each field.

“This was pretty exciting stuff. We were able to plug all that soil test data into a computer and get it to generate a map that looked like the actual field. Lo and behold, with a two-acre sample map, you’re able get a good idea of what that field looks like in terms of organic matter.

“That allowed us to create a nutrient map that documented zinc, copper, phosphate, iron, soil pH, calcium and all the others. In those days, we ended up with about a 30 dollar per acre bill. We had a lot of information and a lot of maps that were fun to look at, but we learned it wasn’t all as useful as we had hoped, especially considering the cost.”

“The most important thing we did learn was that there was some valuable low-hanging fruit in terms of phosphorous, zinc and copper in this field. That map allowed us to write a phosphorous prescription, so every time those numbers are lower than 20 (parts per million), then the prescription map kicks in to add 10 pounds or 20 lb. or whatever is needed.”

Micro-environment — Bulani says the topo-grid analysis did a good job of accounting for nutrients, water and soil structure, but he felt there was still something missing. If he wanted a solid grasp on what was occurring in the field, it would involve more than just the physical and chemical properties of a field.

That’s when he discovered some 30-year old research from Nebraska that delved into the direction a slope faced. The study looked at significance differences in water-holding capacity depending on the summit, shoulder, back slope and front slope.

Not only that, but the compass was also a factor. Water-holding capacity was seriously impacted by orientation north, south, east and west. This particular field was selected for the study because the soil was similar in all zones. That minimized the effect of soil on the results.

“They found that on a north-facing slope, there was 20 percent more crop-available moisture. East-facing slopes were the driest because of the prevailing east winds.”

VR disappointment — Bulani says he has talked to numerous growers who are ready to give up on VR because it doesn’t meet their expectations. He reminds growers that six factors affect yield. The problem usually isn’t the VR plan, it’s the six-part agronomy plan. His Ultimate Yield Management Institute coaches producers to examine all six when thinking about their VR thinking, including:

- seed quality

- nutrient management

- seed placement

- seedbed preparation

- seeding date

- crop protection

Bulani says some guys mistakenly think of VR strictly in terms of nutrient management. They think zone maps and the controller will solve their problems.

“Not so” says the expert. If a grower can score high in each of the six categories, then you can apply VR as a complement to good agronomy. Then you’ll be a successful VR producer.

“When I talk to growers who are disappointed in their VR performance, it’s nearly always because they’re un-willing to change their logistics to employ VR properly or their agronomy program needs some work.

“Guys tell me they VR their nitrogen or they VR just one blend, and they’re disappointed. If that’s all you’re doing, then I would say your potential yield increase is low and your potential cost saving is also low. Why do guys do this? Because it’s easy.

“There are a few growers now VRing a blend of three or four nutrients. I can tell you their potential yield increase is significantly higher, I’d say it’s medium. Potential cost savings are medium and the logistics for them have now become complex.”

UYMI has a chart identifying 10 levels of complexity, each with increasing potential for yield and potential for cost cutting, and naturally an increase in technological complexity. At the highest level, soil building ranks as the only factor with a high potential yield increase. But it has low potential for cutting costs and it’s very complex. He suggests the best plan might be to do only one or two fields a year.

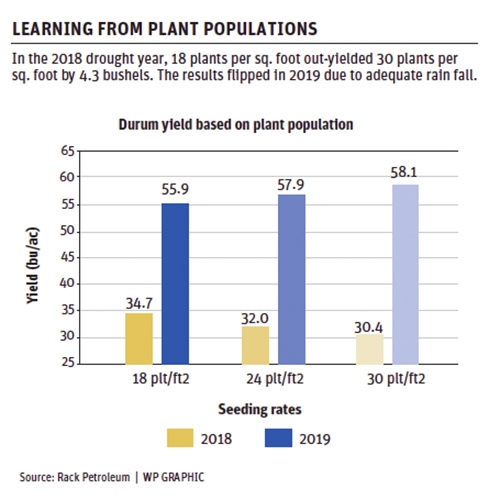

UYMI was part of a durum seed density study at Swift Current in 2018, which was a dry year, and 2019, which was a normal rainfall year.

The seeding rates in both years were 18 plants per sq. foot, 24 plants per sq. foot and 30 plants per sq. foot.

In the 2018 drought year, 18 plants yielded 34.7 bushels; 24 plants yielded 32 bu.; 30 plants yielded 30.4 bu. The lowest and least-cost seeding rate yielded 4.3 bu. more than the highest seeding rate.

The results flipped in the 2019 normal rainfall year. With adequate rainfall, 30 plants yielded 58.1 bu. for a 2.2 bu. advantage; 24 plants yielded 57.9 bu.; 18 plants yielded 55.9 bu.

Ultimate Yield — The AIM on-line event provided a good opportunity for Bulani to show a research drill developed over the years by his Ultimate Yield Management Institute team.

“It’s something like a Swiss Army Knife that does everything. We can do anything and everything we want with this drill all at the same time. We have anhydrous ammonia, UAN, 10-34, seed, dry fertilizer, an Alpine kit for furrow placement of phosphate with P22, we can inject a little zinc in the mix, we can apply inoculant. This is an exciting drill. It allows us to do some really cool research.”

Not every farmer has a research drill, but each year more growers equip themselves with drills with multiple tanks. Using that half-million dollar drill in the fall not only stretches amortization, it also becomes another VR tool.

He says an annual fall VR operation should be as common as a fall weed control operation.

“Use that drill for soil building in the fall when you have time. If you have a three- or four-tank system, you could go in with phosphate, copper and zinc in the fall. That frees up some tanks so you can carry different blends for VR in the spring.”

The institute looks at everything that has a potential benefit for growers. One such new technology is Gamma-Ray Soil Spectrometry to design accurate drainage systems. This method measures the radioactive isotopes as they break down in the soil. Bulani says the technology looks promising.

Although there may be a large number of farmers who want to reap the financial and environmental benefits of VR, Bulani says numerous hurdles stand in their way: logistics, fear of complexity, equipment limitations, disappointment at the lack of verifiable results, cost, time and good VR specialists.

Precision averaging — Bulani warns farmers about precision averaging. VR is dependent on understanding and managing variability in your soil. That variability word is the same one that appears in variable rate.

“Here’s a typical scenario. A farmer comes in and says ‘I want to precision farm and variable rate. My neighbour’s doing it and I want to do it too. Make me you best maps. And make one blend for all my canola so I don’t have switch during seeding.’

“I tell them you are precisely averaging everything you know about your soil variability. That’s not VR.”

AIM presentations are available at https://aginmotion.ca/.

Bulani’s research can be found at www.therackonline.com.