Chemical, biological and physical soil properties vary considerably in space and time, and they need to be closely monitored to have the best chance at a good fertilizer response.

So it’s not surprising that so much energy is devoted to developing new products and techniques that assist fertility programs, considering the eye-popping amount of money spent on fertilizing Canadian crops each year.

But how do you decide which of the new products and services designed to gather soil fertility data will help your fertilizer recommendations hit the top profitability curve?

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Agriculture Canada and research programs at Canadian universities are limited in terms of the research dollars they can commit to new soil fertility assessment techniques. As well, the testing paid for by manufacturers often takes priority and is revealed to the public only if the companies choose to do so.

However, the information provided by manufacturers is often all a farmer has to go off when kicking the tires on a new approach to assess soil fertility.

A common note of caution provided by soil scientists when asked about new technologies or procedures that monitor soil fertility is to make sure they provide insights into what a specific crop actually needs.

Jeff Schoenau, a soil fertility expert with the University of Saskatchewan’s College of Agriculture and Bioresources, said a fertility program should be based on more than just the quantity of nutrients in the soil.

New products and services designed to gather soil fertility data “need to be correlated with the existing approaches, which involve an actual physical collection of a sample and analysis in a laboratory,” Schoenau said.

“They probably also need to be correlated or related to plant uptake to determine if they are providing a reliable indication of relative fertility and availability of nutrients.”

John Heard, a Manitoba Agriculture soil fertility specialist, said new sensors that measure soil nutrients are often correlated with a traditional soil testing approach.

“But they really don’t test what the original soil tests did —that is, how good does it relate to a crop uptake of a nutrient or response to an application to a nutrient. That’s called the grunt work, that’s called doing some field research or studies,” he said.

“Most people don’t want to do that, they just want to take shortcuts and correlate their new laser beam or crystal ball to an existing test that is already out there. And that’s not a hard bar to get over because generally they do relate to some of those tests, but it’s not the same as relating to what the plant actually extracts from the soil.”

However, Heard said many of the real-time sensors are good at identifying patterns in a field that help producers and agronomists with zone management, including visual vegetation indexes, topography, percentage of clay and water holding capacity.

“But none of those pretend to say they know what nutrient levels are there. They are just saying, ‘here is the field that behaved differently or has different yield potentials, and then you use a traditional soil sampling approach to target those areas,’ ” Heard said.

Another note of caution came from Josh Messer, a certified crop adviser with AgIntel Agronomy Consulting, who ordered soil sensors, which are mentioned later on in this story, but he ended up asking for his money back because they hadn’t been delivered nine months after they were purchased.

There are countless startups working to take advantage of the quickly growing and profitable agricultural technology sector, and it can be difficult to identify the companies that will still be around to pick up the phone when you need support a few years down the road.

Messer said he’s always on the lookout for new products that help him and his customers agronomically, save him time or help him apply compounding analytics to the information provided by digital-based products.

“Can I take all the agronomics, my observations and everything else and apply compounding analytics to it to learn from all the things that have been observed and measured throughout that time?” Messer said.

“That third one is the one that nobody has been able to hit.”

Which brings up the question, is the soil sensor providing nice-to-know or just-need-to-know agronomic information?

Messer said he is suspicious of in-field soil sensors that monitor soil nutrient levels.

“I don’t know any that are working and that are calibrated to labs and are giving the information that you need back,” he said.

“Ag tech is all fun and fuzzy from the outside, but when you get into the depths of it there is very little that adds value.”

New soil sensing and testing technologies produce lots of data points for producers to create field zones for variable rate fertilizer and seed applications.

However, a Fertilizer Canada survey shows less than 15 percent of Canadian growers actually used VR application rates as of 2017.

Heard said this study also shows a significant number of growers continue to rely on soil tests to set their fertilization rates.

“For example, in spring wheat on the Prairies, about 60 percent (of respondents) use past experience as their criteria, 50 percent use soil tests and about a third use some type of yield-base measure, or yield expectation. So soil testing is still very much a standard criteria that they use,” Heard said.

In Saskatchewan, approximately 75 percent of survey respondents said they use a flat rate fertilization program that is the same across all of their fields.

This suggests producers find zone management too complicated, or they don’t think it will make them more money at the end of the day compared to a flat-rate approach.

This isn’t surprising considering there are very few independent studies available to the public that show variable rate applications pay off on the Canadian Prairies.

However, there are plenty of producers and agronomists who have field histories in their files that clearly demonstrate profitability from using a VR approach, and more producers could be talked into jumping on the VR bandwagon, as long as it’s an easy jump.

There is room for new technologies to make it seamless for growers to adopt VR production practices, including new soil sensing products that quickly and cheaply detect the soil fertility properties needed to make the right agronomic decisions.

Keeping these cautionary notes in mind, following is a list of new technologies in development or already on the market that are meant to make the tedious job of harvesting soil fertility data more efficient.

The first category of technologies stays within the wet lab approach that uses an extraction process to yield soil fertility data that remains the tried and true approach for fertility management in Canada.

Even though these products are within the current soil testing paradigm, they offer new approaches that either take away the drudgery out of soil sampling, the wait time generally associated with sending samples into a lab, or both.

BoniRob

German engineers have developed BoniRob robot.

A key component of the soil-testing prototype, dubbed Soil2data, is a compact NUTRI-STAT Ion Selective Field Effect Transistor sensor module from Microsoft that was specially designed to test soil nutrient levels.

The ISFET sensor module comprises four individual ISFET sensors and additional components for measuring soil properties.

The sensor can measure nitrate, potassium, phosphate, pH, temperature and electrical conductivity of soil samples.

The compact system takes soil samples with an auger, prepares it for analysis by mixing the soil with water to create a solution and then returns it to the field once the analysis is done.

The robot follows a predetermined path across fields that can be easily set by agronomists and scientists and automatically takes samples, tests them and then uploads the data to the cloud.

It takes the soil-sensing robot approximately 20 minutes to gather and test a soil sample.

SmartCore

Another robotic soil sampler I came across during InfoAg in St. Louis, Missouri, is built by Rogo Ag on a tracked Bobcat.

The SmartCore robot takes soil samples and labels them for subsequent lab analysis.

Drew Schumacher of Rogo Ag said operators unload the Bobcat from a trailer and hit go and it collects and packages the soil and then returns to the edge of the field.

The sample bags are created out of plastic sheets by the soil sampler using heat sealing, which creates a line of bags similar to sausage links.

An important part of the system is a high-speed, self-cleaning auger that provides a high level of depth consistency of the cores and prevents cross contamination between samples.

Schumacher said the machine holds 250 samples and can sample approximately 85 acres an hour on a 2.5 acre grid.

Mobile labs

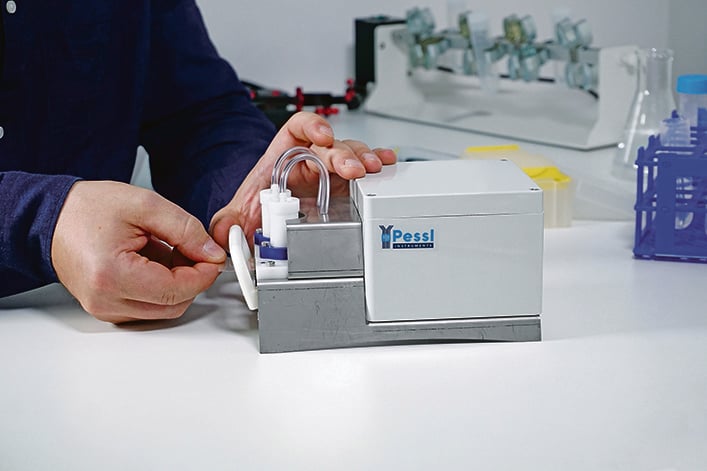

The lab-in-a-box concept by companies including AgroCares and Pessl Instruments still requires users to take soil cores the old-fashioned way.

However, these products provide soil fertility results immediately because they enable on-site measurements in field conditions and can be operated by users without prior laboratory knowledge.

METOS is the Canadian distributor of the Pessl Instruments-built MobiLab, which provides soil and sap nutrient measurement in less than two hours.

Nitrate, ammonia, sodium and chlorine can be measured with the soil analysis part of the mobile lab, and potassium, sulfate, calcium and magnesium can be measured from plant sap.

The METOS MobiLab uses capillary electrophoresis to analyze the nutrients in a soil or plant sap sample, with the company’s Lab-on-a-Chip.

The ions of the chemicals are separated on the chip according to their chemical nature, and the detector then measures the concentration of that particular chemical at the end of the capillary.

The LOAC has a measurement range of three to 1,000 p.p.m. (0.01-0.5 grams per kilogram), a resolution of 0.5 p.p.m. (one milligram per kg), an accuracy of plus or minus three percent for liquid concentrates in p.p.m., and an accuracy of plus or minus 15 percent for measurements of soil concentrations in mg per kg.

The soil nutrient data is related to GPS co-ordinates using the METOS mobile app and sent to the company’s web-cloud, FieldClimate, where it is stored and accessible for users.

The data is easily converted and used with other agronomic software as well as with automatic variable rate applications with precision farm machinery such as fertilizer spreaders and sprayers.

Emerging technologies

Moving away from the conventional soil sampling-soil laboratory approach, we come to emerging technologies that have the potential to disrupt how soil fertility is monitored and managed.

Full-range visible near infrared spectrometers working in the 350–2500 nm wavelength range is a proven technology used by scientists to measure soil nutrients. However, the technology is being miniaturized and becoming more affordable with spectrometers that have limited NIR ranges already available to agronomists.

The University of Sydney funded a study led by Yijia Tang and published in 2020 that evaluated low-cost portable near infrared sensors for rapid analysis of soils from southeastern Australia.

Four portable NIR instruments with different wave-length ranges and sizes were used in this study:

- The ASD AgriSpec spectrometer by Malvern Panalytical Inc. was tested in the 350–2,500 nm wavelength range.

- The PSR-3500 portable Vis-NIR spectroradiometer by Spectral Evolution Inc. was also tested in the 350–2,500 nm wavelength range.

- The NeoSpectra module SWS62221 by Si-Ware Systems uses the 1,250–2,500 nm wavelength range.

- The NIRVascan ASP-NIR-350M-Reflect by Allied Scientific Pro from Quebec was tested in the 900–1,700 nm wavelength range.

“The four portable infrared sensors showed good prediction accuracy in clay, sand, total carbon, CEC, pH, exchangeable Mg and Ca (r2:0.81–0.43), but a poor prediction of silt, exchangeable Na and K,” according to the study.

The ASD AgriSpec and Spectral Evolution with full spectral range (350–2,500 nm) had the best prediction accuracy followed by NeoSpectra (1,250–2,500 nm), while NIRVascan (900–1,700 nm) has the lowest accuracy for all of the investigated soil properties.

The results indicate that the wider the spectral range an instrument has, the better accuracy it can achieve.

The study found NeoSpectra is considered to be the best choice among all the portable instruments with sufficient accuracy performances and relatively low cost, while NIRVascan can also be used in the prediction of certain soil properties such as total carbon, clay and sand.

“NeoSpectra and NIRVascan provide more opportunities for growers, consultants and researchers in soil analysis and decision making in fertilizer management and soil quality management by regularly monitoring soil conditions which will help provide inclusive and real-time information of soils,” the study said.

“We foresee such miniaturized spectrometers will become cheaper in the near future and will be made available to use using a mobile phone. This new technology allows mass adoption of NIR technology for field measurement of soil properties.”

SoilReader

A Winnipeg based startup designed a coulter called the SoilReader that can be mounted on any implement.

The company claims it can accurately read nine nutrient factors while pulled through soil, including nitrogen, phosphorus, potassium, organic matter, pH, EC, moisture, clay and sand.

The disk’s hub has been machined to accept a small NIR spectrometer. A fibre-optic cable runs inside the disc and out to the sensor on the outer circumference of the coulter, where there is a window for a sensor and a 12-volt light.

The company is developing technology that will allow the sensor to drive variable rate fertilizer application in real time, but for now it is creating application zones that can be used on subsequent field passes.

Veris iScan-plus

The Veris iScan-plus is installed on planters or tillage tools and uses four sensing technologies, including an electrical conductivity array, red and infrared optical sensors, a capacitance moisture sensor and a thermopile sensor for soil temperature.

The iScan-plus gives the operator immediate feedback as changes in moisture or soil temperature change across the field, so that planting or tillage depth can be adjusted.

The electrical conductivity and organic matter readings can be used to help create field zones.

Teralytic

Teralytic launched its soil sensor probe in 2018, which uses 26 sensors that provide reports on soil moisture, salinity, NPK at three depths (15, 45 and 91 centimetres), as well as aeration, respiration, air temperature, light, and humidity, 24 hours a day.

Users install the sensors shortly after planting by using an auger provided by Teralytic, and then remove the sensor shortly before harvest. The probe communicates with the cloud via LoRa wireless technology, and users can monitor the readings and analytics through the web interface.

A few sources, including Josh Messer, as mentioned at the beginning of the story, told me that customers paid for the Teralytic sensors but they weren’t delivered.

I contacted Steven Ridder, chief executive officer of Teralytic, whom I interviewed for a story on the soil sensor earlier in the year, and he told me the company is always oversold because demand outstrips the company’s supply chain. As well, COVID-19 shut down all of its manufacturing facilities for most of the year up until August.

However, Ridder said the company is in the process of clearing its backlog and plans to build excess inventory by the spring so it can have same day shipping when an order is made.

NutriScan

ATP Nutrition has teamed up with the Dutch company AgroCares to bring their soil analysis technology to the Canadian market.

The NutriScan uses near infrared and electro conductivity technology to analyze soil nutrient levels in three to five minutes.

“We do nitrogen, potassium, phosphorus, sulfur and then all of the main micronutrients — zinc, copper, manganese, boron, iron. Plus, we have CEC, we have base saturations and we have potassium to magnesium ratio along with pH and organic carbon,” said Dan Owen of APT Nutrition.

“It gives a big, nicely rounded report, and at the moment, I believe it’s one of very few units in the market that actually gives as complete a soil test to include those macros base saturations.”

Users can take the NutriScan to areas of their field that look a little lacklustre, get a soil sample reading and immediately address an issue instead of waiting three to five days to receive data from a core sample back from the lab.

Owen said the NutriScan can be used to test soil-nutrient levels in the same way that a diabetic takes daily tests of their blood sugar levels with a portable machine.

“But if I start to feel the effects of my diabetes starting to play up, I go to the doctor and what they actually do is they take a blood test to look even deeper into what’s happening,” he said.

Similarly, the NutriScan will be used to take many tests with immediate results to identify areas where soil properties need a closer examination with a traditional soil test.

“I don’t think it (NutriScan) will replace the wet lab. I think it complements the wet lab and the way I look at it is the two tools are slightly different … A wet lab, I think of an analytical lab, a very high precision lab,” Owen said.

“When I think of our NutriScan, I think of a diagnostic tool with quite good precision, but it’s not necessarily as high as the lab.”

He said real-time technologies such as the NutriScan will enable growers and agronomists to get a better understanding of the field zones created with yield maps or NDVI imagery from satellites and then fine-tune their variable rate fertility programs.

“This is where the real-time technology fits in because now we can actually go into those fields and look at those zones and we can actually ground truth them using this type of technology,” Owen said.

He said real-time soil sensors are not out-of-the-box solutions — they need to be properly calibrated for the conditions in which they will be used.

To make sure the NutriScan would be accurate in prairies soil, ATP worked with AgroCares for two years and collected more than 2,000 soil samples throughout Western Canada.

“We scanned them (soil samples) with one of the NutriScan units and then those samples were dried, ground and sent to the Netherlands, where they were run through the soil lab. They had 93 different parameters that they actually look at in that soil, and then that was added into a database and an algorithm that actually drives the unit.”

To make sure there is a strong consistency in the results from NutriScan and wet labs, ATP also scanned soil samples and sent them to soil labs around Western Canada.

“We got the results back and statistically analyzed the variance between the real-time analytical tool and the wet lab. So now what we have is confidence that the reading from our unit, whilst the number varies from the wet lab, that number still has a relevance to the wet lab,” Owen said.

The NutriScan will soon be able to conduct real-time tissue tests, which Owen said will enable agronomists and farmers to intervene and fix problems while there is still time.

“That’s what really excites me because when I think of walking into a field, I see a problem and I can take a soil sample, I can take a tissue test from the old growth, I can take a tissue test from the new growth and have all of that data back in my hand within about five to 10 minutes to do all three samples,” he said.

The system uses a smartphone-based app that geo-locates where the samples have been taken.

Users will calibrate the scanner each day by taking five scans of the same soil sample to see if there are any outliers in the readings.

“This is a really nice safety check to ensure that the data we get from it is good. Once that’s done. It sends that data off into the cloud back over to the Netherlands and it’s run through the algorithm that compares that spectra to that database built out of the 93 parameters that were done in the wet lab,” Owen said.

The NutriScan costs slightly less than $5,000, and a subscription fee of $7,200 per year provides unlimited use of the soil scanner analytics.

“It’s going to help us do more because at the moment about 20 percent of western Canadian soils are actually sampled,” Owen said.

“If we don’t sample, how can we build a nutritional plan? I think with this unit, because it’s a fixed cost type unit, we can do more samples in either grids or zones in the field and we can actually sample more fields for a fixed cost.”

Soiloptix

A technology that seems to be getting some traction in North America came out of Europe and is offered by Soiloptix.

The company’s sensor is placed in a two-foot long housing that’s mounted on a truck or all-terrain vehicle.

When the vehicle drives across a field, the sensor constantly measures gamma rays from naturally occurring radio-nuclides such as caesium 137, uranium 238, thorium 232 and potassium 40 and produces 335 measured points per acre.

By working from a few reference soil samples, the company’s software translates the decaying gamma radiation signatures in the first foot of soil into multiple field variability maps, including pH, organic matter, phosphorus, potassium, calcium, magnesium, percent clay, percent sand, percent silt, plant available water and bulk density.

A soil sensor sold on Amazon is just over $600 and built by JXCT out of China. The company claims it provides real time monitoring of soil EC, PH, NPK, moisture and temperature. Just plug the sensor into the soil, push a button on the display and Bob’s your uncle.

It would be amazing if the sensor provides accurate macronutrient readings within seconds, but basing fertilization recommendations on such a product, at least until it’s been verified on Canadian soil, might be a stretch.

However, it’s only a matter of time until one of these sensor manufacturers hit the mark and clearly demonstrates when, where and how such real-time devices can be safely and efficiently used to help monitor fertility.

Edgar Hammermeister, an owner of one of the four franchise regions of Western Ag and manager of professional agronomy in his franchise region, said if a soil sensor can be shown to bring value to a farm, producers will use it even if there aren’t studies that show it works.

“For a farmer, if it (new soil sensor) can be demonstrated to work, they don’t care what the expert says or if an expert is familiar with it. If it works and it brings value to the farm, farmers are going to use it,” Hammermeister said.

Western Ag started operations in the mid-1990s and is the sole operator of the Plant Root Simulator, which uses small soil probes to measure negative charge anion nutrients and positive charge cation nutrients.

The probes simulate the activity of roots rather than simply measuring extractable nutrients to provide measurements of the soil nutrient supply.

Through the company’s PRS CropCaster, it provides farmers a wide array of information on what’s actually available to the crop roots, including 12 essential macro and micronutrients.

Hammermeister said there is a gradient of acceptance of soil sensing technology, and he expects the debate to be around for a long time over what is a reliable and acceptable way to gather soil fertility data.

“From Western Ag’s perspective, we have a quote unquote new technology that’s been around for 25 years, and for some researchers it still needs proving,” Hammermeister said.