BRANDON — Saying that a pump is a pump is like saying that a horse is a horse. It’s not true, especially with pumps that come with high expectations.

Peristaltic pumps probably come with the highest expectations in terms of accuracy, which is why Westfield chose them for its STORM seed treatment plant.

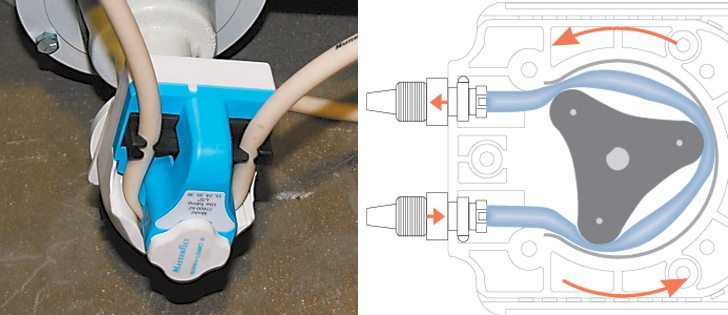

According to a Westfield news release, peristaltic pumps provide precise metering and reduce contamination and maintenance because the chemical never touches the pump components. The product always remains within the delivery tubing. As well, the pump is reversible after each use so there is no chemical waste.

Read Also

Equipment manufacturing may return to Canada

Some ag equipment and automotive manufacturers are now adjusting their production and distribution to avoid tariff costs in relation to supplying the Canadian market.

The flexible tubing that contains the product passes through the pump housing. A main advantage of this system is that the product never touches the working parts of the pump, according to Bayer consultant Bob Reekie.

“Alternating compression and relaxation of the flexible tube pushes the liquid towards its destination,” Reekie said.

“The biggest advantage is that the pump accurately releases the correct volume of fluid with each pulsation.”

An electric motor drives the pump. The r.p.m. of electric motors can be precisely regulated, giving the computer immediate and accurate control over the amount of product being applied.

A rotating shoe at the working end of the electric motor shaft functions much like the lobes on a camshaft. It pushes liquid forward as it rolls into contact with the flexible hose and seals the hose behind so liquid won’t flow backward.

Each pulse sends a specific amount of chemical to the applicator. By changing the r.p.m. of the electric motor, the computer continuously adjusts the chemical volume of each pulse to match the seed volume.