Other fun facts:

Air pumped into slurry tanks mixes the manure. Rising air bubbles promote aerobic bacteria, which digests toxins, fatty acids and ammonia. This reduces manure’s biological oxygen demand and reduces odour.

That’s the concept upon which the Irish-based Dairy Power company based their Smart Manure Aeration system.

Adam Steward of Dairy Power in Canada says the company has produced the aeration system since 1998, selling Smart Manure into 35 countries.

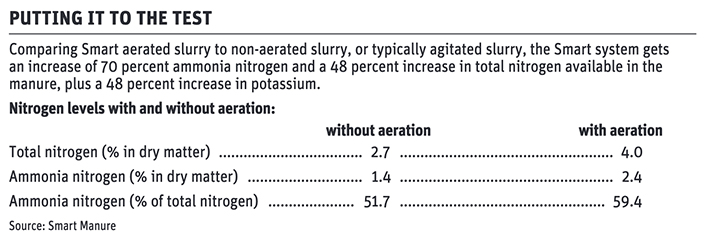

“Comparing Smart aerated slurry to non-aerated slurry, or typically agitated slurry, the Smart system gets an increase of 70 percent ammonia nitrogen and a 48 percent increase in total nitrogen available in the manure, plus a 48 percent increase in potassium.”

Read Also

Growing garlic by the thousands in Manitoba

Grower holds a planting party day every fall as a crowd gathers to help put 28,000 plants, and sometimes more, into theground

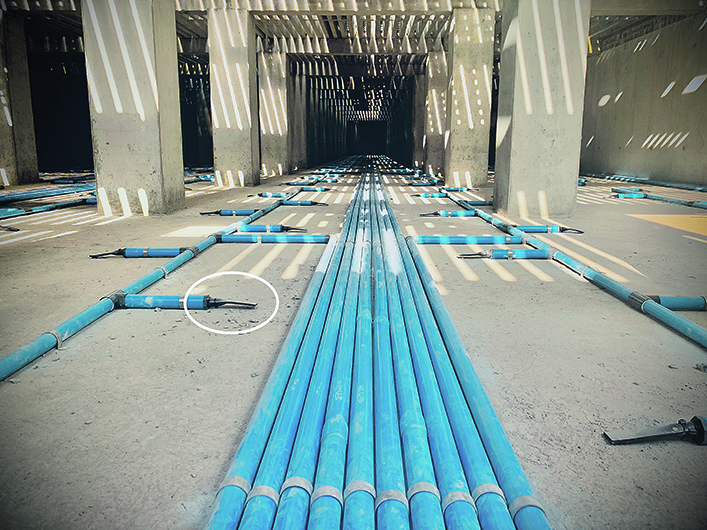

He describes the system, saying it uses two-inch diameter UPVC air supply lines on the floor of the tank, which can be in a building or a round tank out in the open. Air is pumped into these main lines with a blower.

“We use a blower instead of a compressor for a number of reasons,” says Steward, explaining that initial investment in machinery and air lines is less, power consumption is far less and there’s less noise and vibration to bother animals.

“However, the main reason is we don’t want the kind of high-powered jet stream of air you get with a compressor. It just shoots straight up in a narrow inch-wide column. Compressed air doesn’t contact much slurry. We want maximum contact.”

The blower uses a seven horsepower motor to slowly push a large volume of air into the blue UPVC lines at five pounds per sq. inch. The motor has a 5.5 kilowatt draw per hour and is usually located in the equipment room. In the Smart systems Steward has been monitoring in Ontario, the cost for electrical power is less than $3 per day.

He says that every distinct animal group has its own oxygen requirement for breaking down anaerobic bacteria. The University of Minnesota has the best slurry research, along with recommendations for volume of oxygen required to break down slurry. This data is available to the Smart Manure company.

“Air exiting our 1.5 inch wide diffuser outlet at the pit bottom slowly rises to the surface, interacting with slurry all the way up. Those little air pockets released at the bottom turn into a four-foot diameter ripple by the time they finally bubble up to the surface.”

“Rising through seven feet of slurry, the air columns contact most of the slurry, thus promoting aerobic bacteria to digest toxins, fatty acids and ammonia.”

The key to making a single blower provide enough air to service a large tank is to run only one section at a time. This is accomplished by their unique air distribution device called a rotary valve. It can be compared to a conventional auto distributor that uses a rotor to trigger power to only one sparkplug at a time as it rotates.

In the case of the Smart Manure rotary valve, there is just one inlet for the air and multiple outlets to pressurize many blue lines. Only one outlet can be open at a time. As the blower runs, the rotary valve opens an outlet for one minute, sending blower air to one of the blue lines. When that air feed finishes a minute later, the rotary valve turns to the next blue line.

Each two-inch mainline has up to a dozen aeration points, spaced every four feet. When air comes flowing down the mainline from the blower, it naturally equalizes the volume among the dozen one-way valves in the aeration points. The aeration point diffusers open to let air escape into the slurry.

Each main line has air for one minute, then the rotary valve turns to the next line for one minute. They call it a cycle when all the lines have been served. When it rotates to the next line, there’s a bleed off pressure relief valve that automatically activates. The lines are all empty before the rotary valve blows into the next line. Every aeration point has a rubbery neoprene one-way flapper valve that closes when air flow stops, and is held closed by slurry pressure.

He says they run these cycles three or four times a day, depending on the kind of manure and its consistency. It only runs a few hours a day, so hydro costs are low.

“Livestock producers never need to agitate their manure tanks again. The slurry is always in a liquid pumpable state, so it’s ready when you are.

“Safety is a main benefit of Smart Manure. We provide such a high volume of oxygen to the slurry that we foster aerobic bacteria, which in turn consumes the anaerobic bacteria. In conventional systems lacking oxygen you get odours, but more importantly it generates high concentrations of ammonia, methane and hydrogen sulfide gas.

“We don’t let those high concentrations develop because we don’t allow a crust to form over the top. That crust is the killer. It eliminates oxygen and houses the anaerobic bacteria. Those toxic gases are locked in and hard at work under that crust.”

Nutrient stratification doesn’t occur in the slurry because the air agitates a couple times per day. They have found that air agitation eliminates the need for any other agitation. That means a farmer or municipal engineer can eliminate the aeration tractor and all associated aeration equipment.

“I think eliminating those lethal gases will be the biggest factor for people considering the system. We all know of people who have succumbed to these silent killers.”

The science of scent

The sense of smell is important to the survival of nearly all creatures. We rely on scent to find safe food, to avoid danger, and even to find a mate.

But how does it work?

Your nose is equipped with olfactory receptors, each having about 1,000 genes. Each gene is tuned for only a small number of odors. When you breathe in, microscopic particles called odourants are sucked in through your nostrils and over the olfactory epithelium, where receptor neurons analyze the particles and send the appropriate message to the brain.

Other fun facts:

- Humans can recognize about 10,000 distinct odours.

- Your sense of smell is stronger when you’re hungry.

- Women have keener noses than men do.

- Your sense of smell is worst in the morning and improves throughout the day.

- Men say the scent of a woman is more attractive at certain times of the month.

- If your sense of smell is affected by illness or injury, your sense of taste will also diminish. About 80 percent of the flavors we taste are actually from the odourants we smell.

- Aerosol sprays cannot eliminate bad smells. They only introduce a stronger odour while the offending microscopic odourants continue to enter the nose. The only way to eliminate odourants is through controlled biological activity at the source.

Source: Staff research