The Saskatchewan initiative prepares for autonomous field implements with precision ag, digital ag and autonomous ag

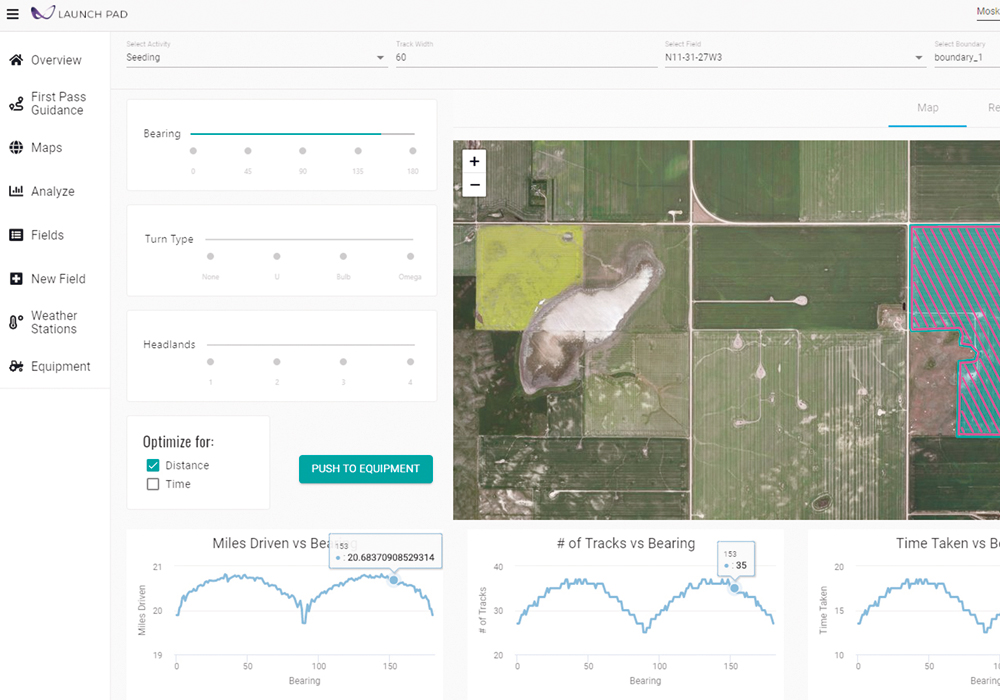

Launch Pad is the next big endeavor in the future of precision farming for First Pass, the Saskatchewan company known for specializing in designing optimal field pathways for implement traffic.

Launch Pad brings together the three main factors that will dominate the future of field operations, according to Wilson Acton, an executive of Verge, the company that bought First Pass a year ago.

Acton the three factors forming the foundation for Launch Pad are precision ag, digital ag and autonomous ag. Verge is one of the few companies already preparing for the advent of autonomous farm machinery.

Read Also

Growing garlic by the thousands in Manitoba

Grower holds a planting party day every fall as a crowd gathers to help put 28,000 plants, and sometimes more, into theground

“Launch Pad is the confluence of where these major forces meet. The concept of precision ag has been with us since the mid-90s with GPS and higher resolution imagery and prescription maps. Digital ag utilizes the data we’ve been collecting from the farms to generate better insights and better decision making.

“Autonomous ag equipment is obviously where the big manufacturers are heading. It includes everything from retrofits like SmartAg all the way to fully autonomous implements at John Deere and Case and others. That’s on the horizon, and we have it as one of the three legs in Launch Pad.

“The important part of Launch Pad is how we tie these three forces together through the operational lens. We need to automate and optimize the operational decisions across the whole farm. This is a planning interface that allows a grower to look at all the fields in one place and then plot the pathway for equipment.”

Acton says the grower can plan how to deal with slope, obstacles, machine size, crops or any other factor affecting the efficiency of field operations.

He says the net result is reduced fuel consumption, less hours on implements and reduced inputs. More efficient use of equipment also means less time spent seeding, spraying and harvest.

“Growers get more done in the same operational windows. After the harvest of 2019, folks are seriously looking at how to get more work done in the same operational window.

“As for autonomous equipment, we’re already equipped. It’s built into Launch Pad. Once autonomous machines arrive, they need to bridge the gap to the conventional world. They need to interact with today’s world. That’s what Launch Pad specializes in. It will be available in 2020.”

Acton says the original First Pass system remains Verge’s in-field operations optimization tool. It’s an A/B implement guidance system that factors in field size and shape, obstacles, potholes, poles, equipment size and any other element that will impact field operation efficiency.

“A lot of people don’t know that First Pass also considers topography, slope and erosion. With our customers in the southern U.S. and South America, the interaction between implement operational direction and erosion are major considerations.”