On the Farm: The Hamills’ decision to get into the malting and marketing of barley took them half way around the world

PENHOLD, Alta. — The Hamill family are accustomed to taking risks. After all, they’re farmers.

So when they made the decision to tap into Alberta’s burgeoning craft beer scene by malting and marketing their own barley, they knew there were no guarantees.

Little did they know that their “barley to bottle” journey would take them to the other side of the world and back.

It started simply enough. Joe Hamill was an avid home brewer. His father, John, grew malt barley.

“We got obsessed with getting Dad’s barley into Joe’s beer,” says Joe’s older brother, Matt.

Read Also

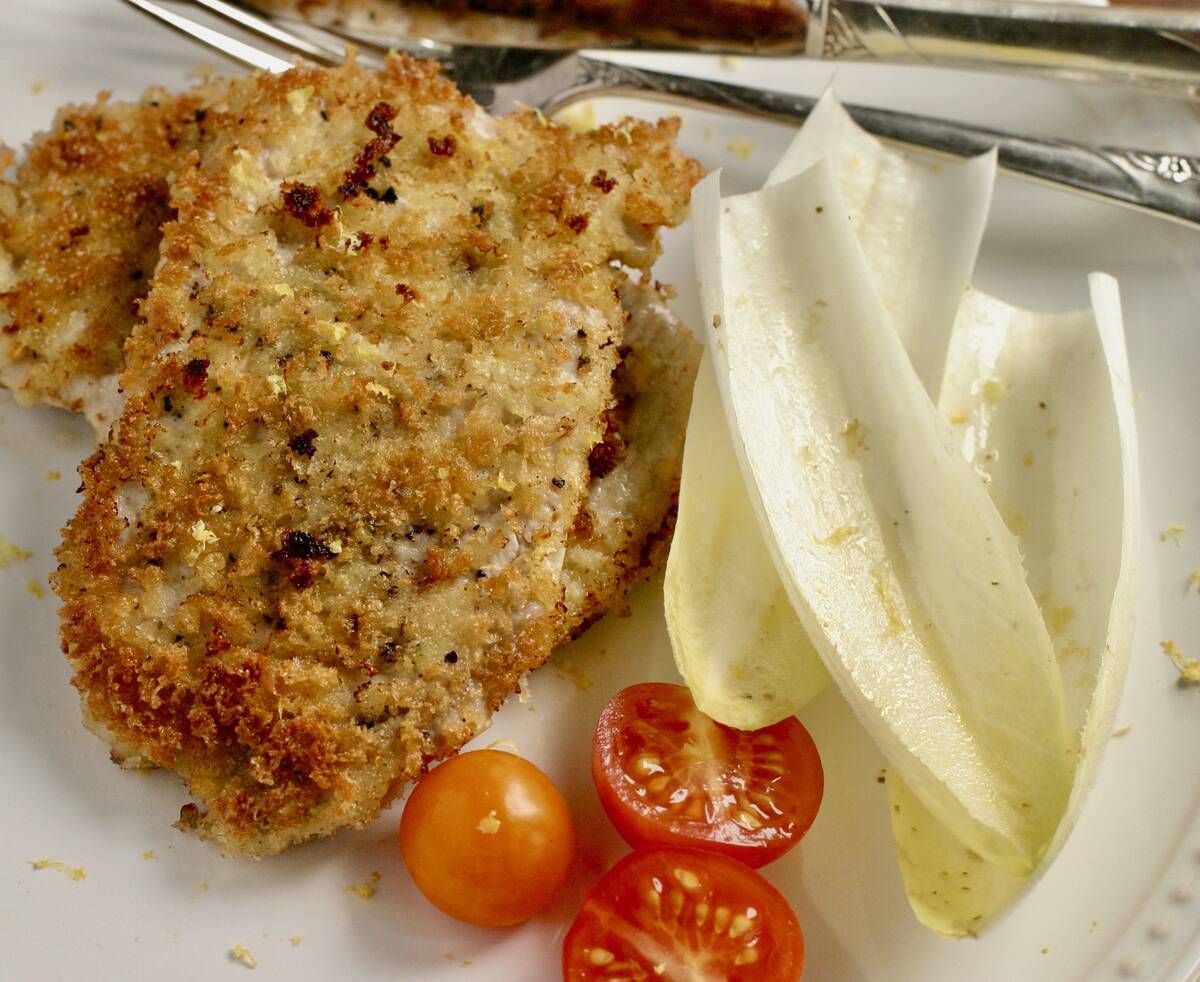

Nutritious pork packed with vitamins, essential minerals

Recipes for pork

It was something the whole family, including the boys’ mother, Susie, and Joe’s wife, Daelyn, regularly discussed around the kitchen table.

They all agreed that with the current attention on traceability in agriculture backed by the movement to eat local and support local, the idea of using home-grown barley in locally brewed beer was a natural fit.

Today, each member of the family plays a part in the operation of their on-farm business. Red Shed Malting was incorporated in 2014. The first malt was produced the following summer.

“We really focus on the specialty malts and fill the role of middleman between the farmer and the brewery,” says Matt.

Specialty malts give beers their individual colour, flavour and aroma characteristics. Matt says that these attributes are manipulated by varying the time and temperature during the final roasting process. Base malts provide most of the fermentable sugars required to make beer.

Behind the dream was months of research, planning, and education.

Matt and Joe completed theoretical and practical hands-on training through the Malt Academy at the Canadian Malting Barley Technical Centre in Winnipeg.

The Hamills worked with Alberta Agriculture, which completed a feasibility study that indicated that most specialty malts purchased in Alberta are imported.

In 2017, Matt visited Australia, New Zealand, Brazil and the United States as a recipient of the Nuffield Farming Research Scholarship. Over a two-month period he experienced first-hand some best practices to help guide the way.

The family established relationships with local craft brewers and industry experts, who gave useful advice and encouragement.

“Early on, we got the blessing of a head brewer at Alley Kat (Brewing) in Edmonton,” says Matt. “When they opened up our bag of malt, and looked at it and smelled it, their eyes lit up”.

Feedback and support from the industry assisted the Hamills in their decision to proceed and helped them to choose the size and design of their malt house, which they built in the back half of John’s new “red” equipment shed.

Matt’s day job as an agricultural banking specialist provided valuable insight into financial aspects of the venture.

Timing of Red Shed’s entrance into the craft malt niche market was right. The 2013 regulatory changes in Alberta saw the removal of minimum production limits required to commercially sell beer. Craft breweries were sprouting up across the province.

“When we started there were about 20 craft breweries in Alberta,” says Matt. “Now there are over 100.”

That number is still growing.

As a small craft maltster, one of just a few across Western Canada, the company is able to custom malt at the request of their buyers, which include breweries, distilleries, and home brewers.

Not everything fell into place easily. A major challenge was finding equipment to suit their specifications. Production capacity of Red Shed Malting is five tons of malt per week, a minuscule amount compared to some of the big players in the industry. The company has a three ton steep tank and two three ton germination kiln boxes. Their malt roaster produces up to 120 kilograms per batch.

“No one in the world had equipment for the size of malt house we wanted to build,” says John.

They managed to connect with engineers in China.

“We went over there and talked to engineers who designed and built the equipment.”

Finding the right company, communicating their needs and awaiting shipment caused a high level of anxiety. This was somewhat offset with faith in the process and in the end, they worked through the issues.

The entire family is involved in the business. John grows the barley. Susie does the books and invoicing and takes calls. Matt’s in charge of sales and deliveries. Joe, the only full-time employee, does the production and malting. Daelyn manages social media. Even little Isabella, 2, Joe and Daelyn’s daughter has a role. She snacks on the malt.

“We want it to be safe,” says John.

With increased consumer concerns around food safety and production, the family encourages transparency and communication surrounding their on farm processes. They participate in Alberta Open Farm Days.

“It’s a chance to meet the consumer,” says John, “to show them how we farm, where we farm, and that we’re sustainable”.

The Hamill family has been growing barley in central Alberta since 1929 when Bernard Hamill emigrated from Ireland with his wife and six children.

“They were looking for new opportunities in a new country,” says John, Bernard’s grandson.

Ninety years later, this fourth generation operation farms 2,200 acres. In addition to 745 acres of barley they grow wheat and canola.

And now they’re first generation maltsters.

“It never gets old to go into a liquor store and see bottles on the shelf that contain our malt,” says Matt.

Matt and Joe also run Hamill Brothers Brewing, whose primary purpose is to brew sample ales for end product taste testing.