First it was Seedhawk, and then one by one, air seeder cart builders began offering sectional control as an option for producers. And given the option, most have chosen it, dealers say.

It’s the solution to that frustrating feeling of driving a mile down a field, doubling up on the seed and fertilizer for half of a seeder or knowing that beside every pothole in a field there is not only waste but impeded agronomy with lodging and over-competitive crops.

However, buying a new seeder cart with section control is expensive.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Intelligentag of Fargo, North Dakota, has spent the last couple of years developing a bolt-on solution, at least for the venerable Deere 1910 air seeder cart.

A few companies, including Romafa of Arborg, Man., build stainless steel replacement metering and manifolds for the machines.

Related stories in this tillage and seeding feature:

- Big planter gets best features of small sister

- Deere’s precision tillage grows: more models added to green line

However, the Fargo company, which is a joint venture business comprising farm equipment giant Agco and technology company Appareo, is the first to offer a sectional control upgrade for the machines.

The company’s first product was its auditory driven blockage and rate meters for air seeding equipment.

“The (sectional control) works with all the 1910 carts with ground drive, and there are a lot of those out there,” said Alan MacDonald, who looks after Intelligentag products for the central and eastern Prairies and Ontario.

The electrically activated gates open and close automatically as the drill or seeder passes over the previously planted crop.

“It ties right into the 2630 monitor. They are simple to install. A farmer can do it themselves. And provided the housings and tubing (under the tanks) is in good shape, they go right in,” he said.

“For some folks, it will be a good time to consider some other aftermarket parts down there as well.… We’ve put them on (1910s) with the aftermarket parts installed and it was dead easy.”

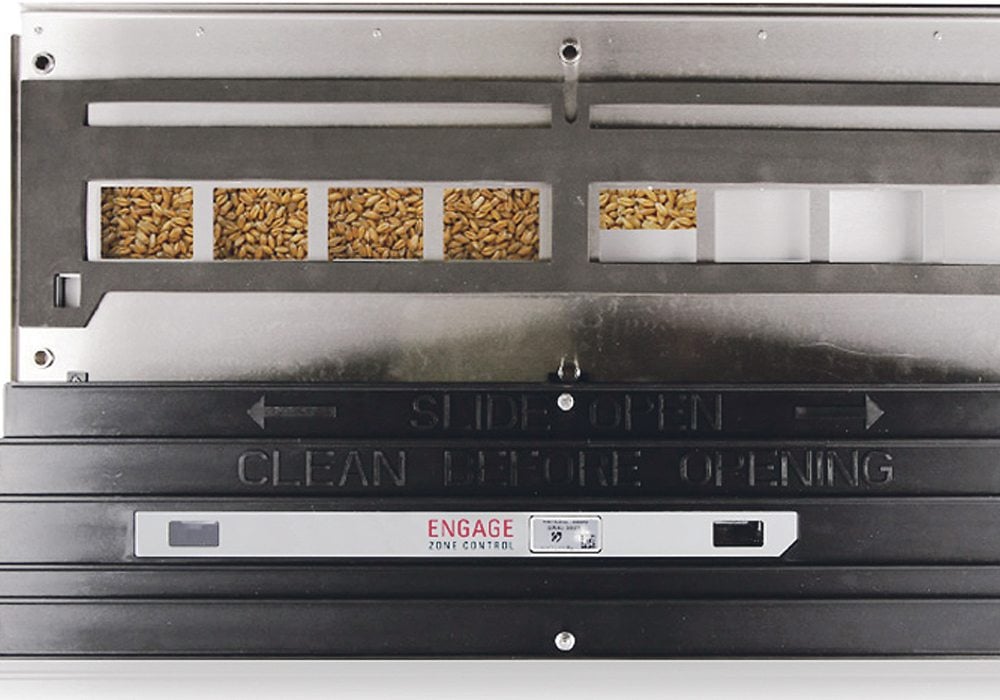

The company calls the system Engage Zone Control, and it will manage eight sections per cart and can be installed under the meters for up to three products.

Made of polyurethane and stainless steel, the components are resistant to both wear and corrosion, says the company.

The stainless steel gates are about an eighth of an inch thick and are bevelled at the leading edge so as not to pack material into the receiver slots.

“That was one of the things that was modified in the testing. There has been a lot testing and now we are releasing them for the 2018 season,” said MacDonald.

In cereals, the system can produce small surges of material when gates are reopened, but the company says it is a minor issue compared to overlapping. When running canola, blocks are slipped into the meter units to restrict the flow and stop surging when the gates reopen.

“The price of a new cart can create a big decision, so an upgrade can be a solution for a lot of farmers with an otherwise perfectly good cart,” he said.

The price for a single tank unit is $11,700, $19,500 for two and $27,300 for three.

John Deere offers sectional control on a new 1910 cart as an option that costs about $32,000 on a three-tank, 550 bushel 1910 unit, but the whole cart will cost slightly more than $200,000 to get that control.

For more information, phone MacDonald at 306-541-3320.