PAMI celebrates advances in agriculture

HUMBOLDT, Sask. — Air drills, tractors, sprayers and combines have been recognized as the Big Four of agricultural innovations that led Saskatchewan to build a $6 billion grain and oilseed industry.

The Prairie Agricultural Machinery Institute of Humboldt, Sask., celebrated 35 years of innovation by naming the equipment as critical tools in the industry.

“To see where you are headed, you need to know where you’ve been,” said PAMI president Dave Gullacher.

“Honouring the Big Four will give us a clearer picture of the path of modern agriculture.”

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

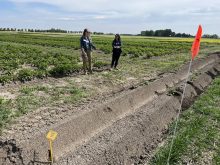

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

The Saskatchewan government used the Nov. 1 event to announce nearly $1 million in funding for PAMI and its Western Beef Development Centre.

“In order to continue to keep the economy of the province going and meet our objectives in the growth plan, we’re going to need the kind of innovation that we see from PAMI to continue in the future,” said agriculture minister Lyle Stewart.

PAMI employees 107 staff and has a budget this year of $15 million.

“We can typically demonstrate $20 per dollar of return in terms of wealth and jobs in the agriculture sector,” Gullacher said.

“Research that’s going to be used by producers can often have a bigger benefit than research staying inside a manufacturing plant because the implementation of it is on a much bigger scale. You have millions of acres to implement any given piece of technology in agriculture, and that’s where you get the big benefit.”

The air seeder topped the list.

“The very first thing that comes to mind in the Canadian prairie region and really in particular, Saskatchewan, has produced the very best dry land seeding equipment in the world, no question,” Gullacher said.

He said the innovations developed with zero till and direct seeding equipment were game changers.

“There’s no other area that has relentlessly, unceasingly worked to develop seeding equipment. It began to occur back in the ’70s and it has really just gone full-bore from then until today,” he said.

Gullacher said continual upgrading has met the challenges.

Jim Bessel agreed.

“The first pillar is where it all starts,” said the former agronomy specialist with the Canola Council of Canada.

“It’s putting the seed in the ground and how we manage it from that point forward.”

Bessel said the concept of precision seeding still needs fine tuning, particularly with canola and small seeded crops where input costs are high.

“Yes, you do have a higher return per acre in relation to gross margin, but it’s the net benefit, whether or not at the end of the day you still have something left in your pocket,” he said. “Saying all that, we still have a ways to go to be a little more precise when we look at the whole idea of seeding.”

The tractor, number two on the list, has become a close companion to the seeder. At one time it was an all-purpose tool, but its job on the farm has become more specialized.

“It’s main task is to pull the seeder equipment for most of the farming that’s done in Saskatchewan,” said Gullacher.

The needs of the seeder have helped shape and design the modern tractor.

“The changes in size, power, traction, navigation, emissions and operator comfort and safety really have changed hugely over the 35 years that we’ve (PAMI) been here,” Gullacher said.

The sprayer is number three on the list.

“We know that spraying isn’t for everybody, but in terms of the overall time use, it’s a huge contributor to what’s happening,” Gullacher said.

Sprayers have become big and fast, and Gullacher said they will become increasingly important in the evolution of future technology.

“They do the best job possible at this point in time of depositing the spray on the soil. Navigation for 24 hour operation and safety are all things built into those sprayers over the last few years.”

Combines have seen advancements in terms of size, effectiveness, navigation and control, particularly over the past two decades.

“The combines of today are four times the size in terms of harvesting rate of the harvesters that we began to test when PAMI started in the ’70s. That basically means that one operator can do the work of four operators back in those days. That is going to be key going forward as we have fierce competition for labour and skilled workers in this province. Even though they’re four times the size, they’re losing only about half of the grain that harvesters would typically lose back in the ’70s,” he said.

“They’re now satellite guided, they can now be adjusted on the go from the operator’s seat and there are just a number of other advancements from the ancient processes of reaping, threshing and winnowing. Those things are still there in the combine.”

Terry Youzwa, a farmer from Nipawin, Sask., said he appreciates the advancements made in farm equipment.

“We’re getting more efficient and it’s becoming more economical. As it becomes more common use, the technology improves and the cost comes down,” said Youzwa.

“We’ve seen that with guidance systems.…They improve your ability to operate more effectively, more efficiently, improve your footprint, but they also make you more productive and you get more out of a day with reduced fatigue.”

The Saskatchewan government hopes to increase crop production in the province from 26 million tonnes per year to 36 million tonnes per year by 2020.

Bigger, faster and smarter machines will help achieve these goals.

“We need to produce another 10 million tonnes on top of what we’re doing now of agricultural products and we’re going to have to really stretch the envelope to be able to do that, but we must do it,” said Gullacher.

“The key innovations that we see are going to come from the crop scientists, fertilizer specialists, people who develop sprays, pesticides and inoculants. Machinery must fit in and accommodate the production of those new varieties and bigger tonnages of those varieties.

“So we’ll be in an enabling role. The machinery is always the enabler that carries out the process for production.”