Having the optimum harvest capacity is difficult when each year can be so different.

It’s only the beginning of September and harvest is advancing quickly in many areas, with some producers in the south already finished and with others soon to follow. Last year, dubbed the harvest from hell, combines were still rolling at the end of October and into November.

Weather patterns can of course change on a dime and what seems like an early, easy harvest can quickly bog down due to rain or even snow.

Read Also

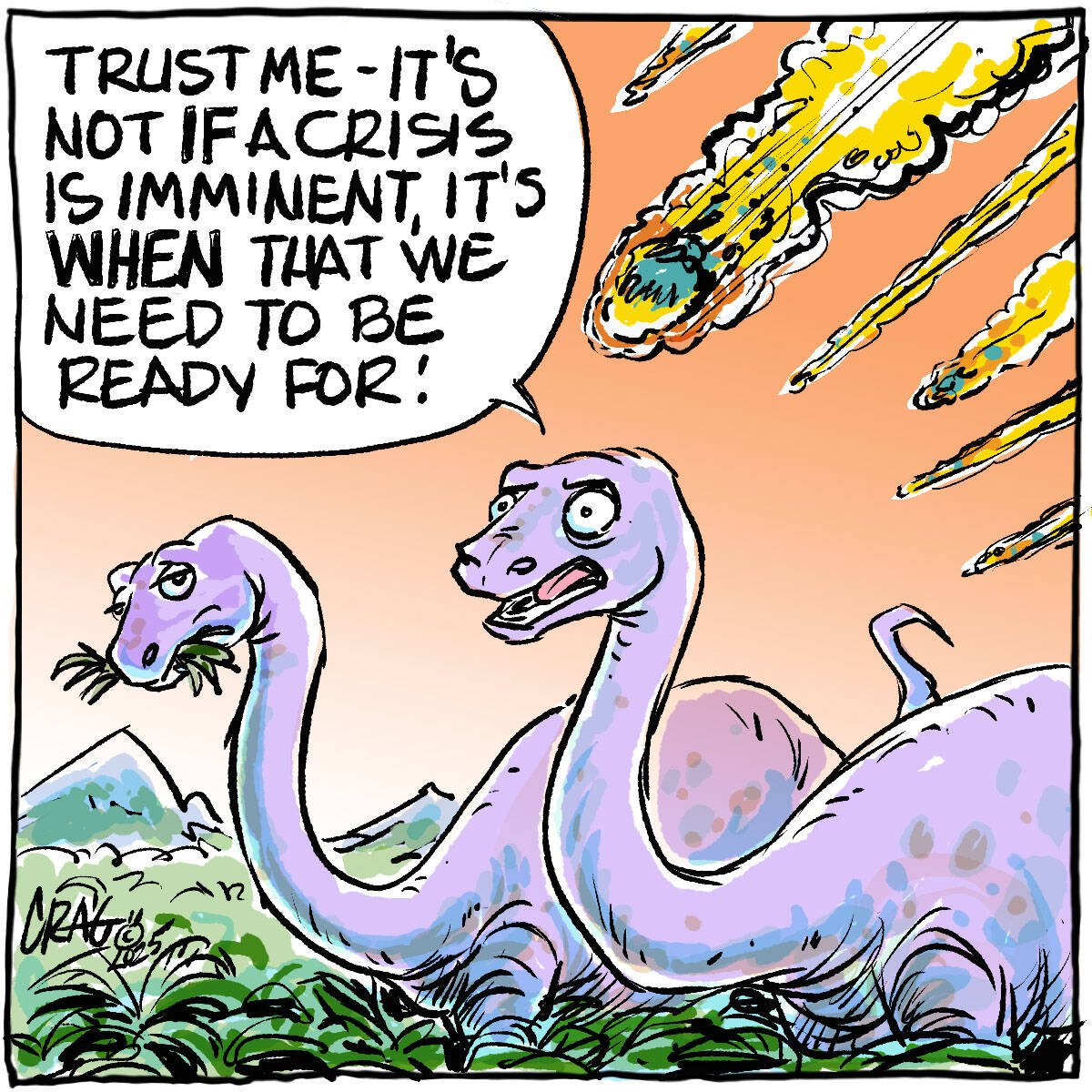

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

So far, conditions this year have been dry and hot over a large portion of the Prairies, in contrast to last year’s rainy, cool weather. Investments in aeration and grain drying capacity were spurred by the 2019 harvest, assets that might be underused this year unless the weather makes a big U-turn.

Beyond harvest weather, grain volume can vary dramatically from one year to the next. Grain storage designed to hold a normal crop can be totally inadequate when a bin buster comes along and that can be aggravated by unexpected delays in new crop movement off the farm. Grain bags are one answer to yield variability, but many producers continue to increase their storage capacity.

What’s best — being among the first in your area to finish harvest, being among the last to finish or being somewhere in the middle of the pack? The answer, as with so many questions, is it depends.

If you’re among the first to park your combine, you’re avoiding weather risk. Everything is safe in the bin. Probably, you also seeded earlier than many of your neighbours. It could also be a reflection of crop choice and not growing crops that are later to mature. However, finishing early might mean you have invested more in harvest equipment than you actually need.

Being one of the stragglers in your area, churning away in the field after others are long since done, can have many causes including late seeding, equipment breakdowns, lack of labour, insufficient combine capacity, crops delayed by hail damage and growing crops that need more time to ripen.

Being among the last to park the combines is not necessarily bad, but it can put you at risk of crop quality loss.

Most producers are comfortable wrapping up harvest somewhere in the middle since it provides them with a feeling of being right-sized on harvest capacity. In difficult years, everyone wishes they had more capacity. In easy years, you could get by with less.

In wet years, fields can be too soft for trucks causing grain carts to take on added importance. In years like this one you might be dragging a water truck or tandem disc to each field for fire control.

Aeration fans on bins run steadily for weeks on end some years. In other years, they can see minimal use.

Grain dryers are common in much of the central and northern grain belt, but the hours of use and the amount of propane or natural gas consumed varies dramatically. Dryers can sometimes sit dormant for years until a wet harvest comes along.

Seasonal harvest help may be needed for one month or three months depending on the size of the crop and harvest weather. Many of the people you rely on for help may not be that flexible in their availability.

A harvest from hell can spur investments that are underused. Easy harvests can lull you into a false sense of security.