A new process developed by researchers at the University of Saskatchewan will significantly reduce the amount of time required to detect harmful mycotoxins in grain, including deoxynivalenol or DON.

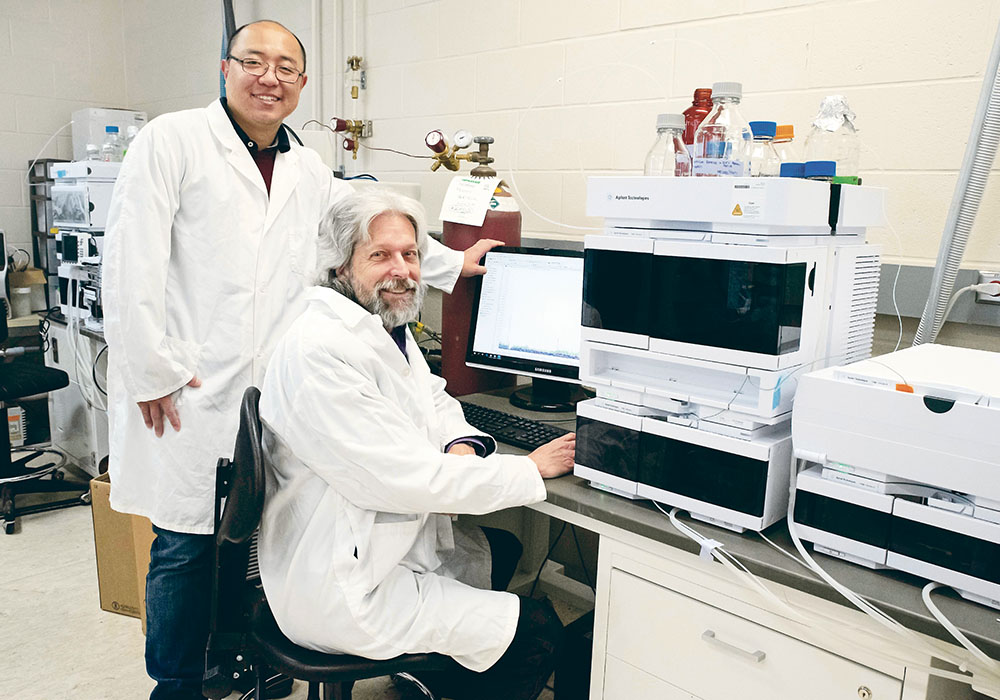

The process, developed by U of S researchers Lipu Wang and Randy Kutcher, involves a simplified one-step mycotoxin extraction process that uses the chemical solvent acetonitrile.

“This method is more accurate and more sensitive compared to existing measures that are currently being used,” said Wang, a research officer with the university’s Crop Development Centre (CDC).

Read Also

Agriculture ministers commit to enhancing competitiveness

Canadian ag ministers said they want to ensure farmers, ranchers and processors are competitive through ongoing regulatory reform and business risk management programs that work.

“Our system has a very high sensitivity, meaning we can detect very low concentrations of mycotoxins in grain samples, and we can also do (it) more quickly and more efficiently.”

The new method is being used exclusively by academics but it could eventually be used by grain companies to manage grain quality.

“Our customers want no contaminants — no toxins — in our grain,” said Kutcher, a U of S plant pathologist and strategic research chair in cereal and flax pathology at the CDC.

“It may also help in deciding whether grain should be processed as food or animal feed.”

In recent years, grain-borne mycotoxins including DON have become a common concern among Canadian farmers, grain buyers and processors.

The mycotoxins, which can be harmful to human and animal health, are typically found in fusarium-infected cereal grain, particularly in regions where humidity and moisture are abundant during anthesis.

Fusarium head blight (FHB), a fungal disease that affects kernel development, causes millions of dollars in annual losses in Canadian cereal crops such as barley, wheat and oats.

In a worst case scenario, grain that contains high levels of mycotoxins can reduce the market value of a crop to zero. Livestock that consume infected feed can experience reduced growth rates, lower fertility, compromised immune responses, and in severe cases, death.

Because of this, the development of new crop varieties more resistance to FHB has emerged as a high priority among plant breeders.

Wang described his new mycotoxin detection system as being faster, more accurate and less expensive than existing detection methods.

More rapid analysis means increased laboratory throughput and more immediate results for plant breeders, who are often dealing with hundreds or thousands of samples at a time.

Submitted samples of grain are first ground into flour or small particles and then mixed with acetonitrile. The mixture is then allowed to incubate for two hours, allowing the mycotoxins to be extracted.

Extracted mycotoxins are then injected into a mass spectrometer where the toxins are identified and quantified.

The new process can facilitate the processing of more than 350 samples per day, using a mass spectrometer. Previously, a lab with access to a mass spectrometer might analyze about 50 samples a day.

“The problem has been that crop breeders and researchers have lacked a way to measure DON that is both quick and accurate,” said Wang.

“Analysis that previously took 20 minutes per sample can now be done in less than two minutes, which is very important when testing thousands of samples.”

“This new method offers breeders a much more efficient way to select wheat or barley lines that accumulate less DON.”

Wang said the system is being used in academic settings, although it could be used more widely, perhaps by the commercial grain industry.

However, the new system requires access to a mass spectrometer.

Wang said the university is exploring commercial applications for the new system, possibly on a fee-for-service basis.

“When we started the project back in 2017, our goal was to develop a high-throughput method for breeding programs,” said Wang.

“Right now we are very confident that this assay is very stable and reproducible.”

The new detection system was developed with financial support from Saskatchewan’s Agriculture Development Fund and the Saskatchewan Wheat Development Commission.