U of S scientist developing home-heating fuel made with canola meal as well as oat and canola hulls and mustard meal

Many prairie people are adept at heating their homes efficiently and minimizing heat loss during Canada’s long, frigid winters.

But there is always more to learn when it comes heating buildings more efficiently and sustainably.

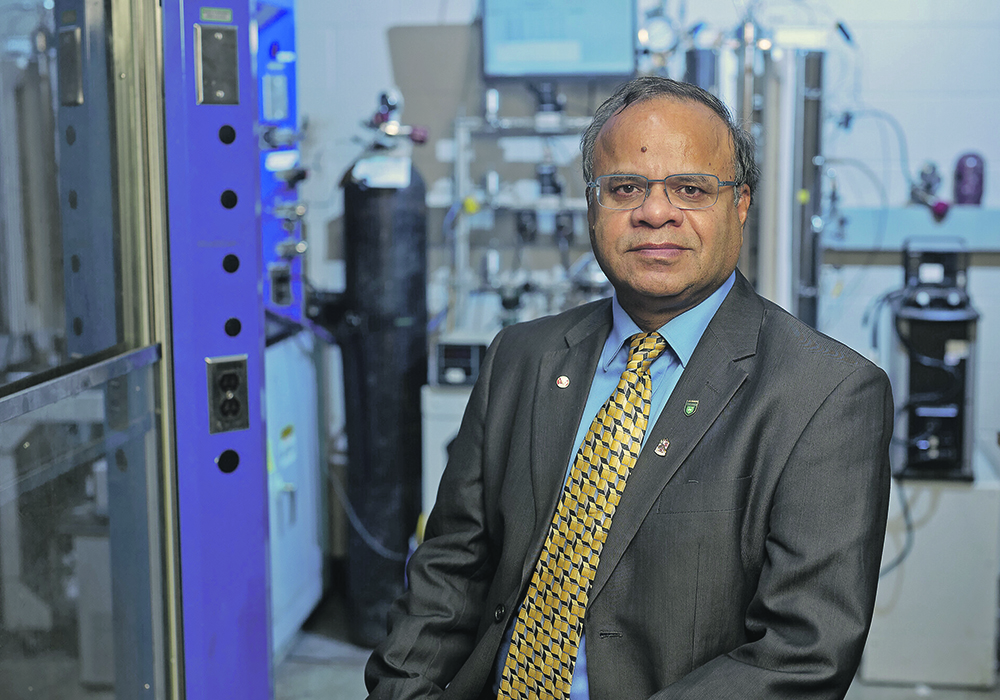

That’s why scientist Ajay Dalai is so excited about developing new bioenergy sources at the University of Saskatchewan in Saskatoon.

Dalai, a petrochemical engineer, is developing a new home-heating fuel made with canola meal. He’s also looking at the potential of other low-value agricultural materials such as oat hulls, canola hulls and mustard meal.

Read Also

Members of Parliament get earful about need for regulatory reform

Canadian farmers have long complained they don’t have access to products as quick as their American counterparts because of Canada’s rules.

Dalai’s work is still years away from contributing to Canada’s energy needs, but he thinks canola-meal heating pellets have a promising future.

“Canada already exports about $300 million worth of pellets (annually) from the forestry sector to Japan, the United States, the (United Kingdom) and other countries,” Dalai said.

“But we really don’t produce any of these kinds of pellets from agricultural materials, even though we have a lot of materials in our backyard.”

Saskatchewan’s advantage in bio-pellet production rests in the fact that the province contains nearly half of Canada’s agricultural land.

Over the years, Dalai and his research team have looked at various materials that could be used to produce a high-quality pellet that could supplement home-heating and energy needs.

Canola meal is an obvious choice.

In 2019, Canadian farmers produced more than 19 million tonnes of unprocessed canola, including about 10 million tonnes in Saskatchewan alone.

Much of Canada’s canola production is exported but a significant amount — nearly 10 million tonnes in 2019 — is crushed domestically to create canola oil.

When a tonne of canola is crushed, about 40 percent of the seeds’ weight is extracted as oil and the other 60 percent produces canola meal.

Right now, the majority of canola meal is sold as livestock feed.

But as canola crushing capacity continues to expand, Dalai believes the amount of canola meal produced will increase, eventually outpacing demand from the livestock sector.

Saskatchewan’s annual crushing capacity could conceivably increase by four or five million tonnes over the next few years, he added.

“Canola meal contains some protein so it’s a good animal feed, but when you export large quantities, of course it costs money,” he said.

“If we can use all of that (meal) for the livestock industry, then so be it….

“But can we do it? Probably not. We’ll probably have lots of leftover canola meal to deal with… and therefore, we’ll need to find new ways to utilize it.”

Dalai concedes there are a few issues that need to be addressed before canola biopellets are produced commercially in Saskatchewan.

For starters, a formulation or recipe will have to tested.

The economics of pellet production will also have to be proven before large-scale investments in pellet-making infrastructure are made.

Dalai and his research team — with the help of the Canadian Light Source synchrotron at the U of S — have already developed a “very good recipe” using canola meal.

Plans are in place to begin small-scale production.

To ensure a marketable product, the intensity of the source material needs to be increased by four to 10 times, Dalai added. Once the pellets hold more energy per unit of mass, they can be transported economically.

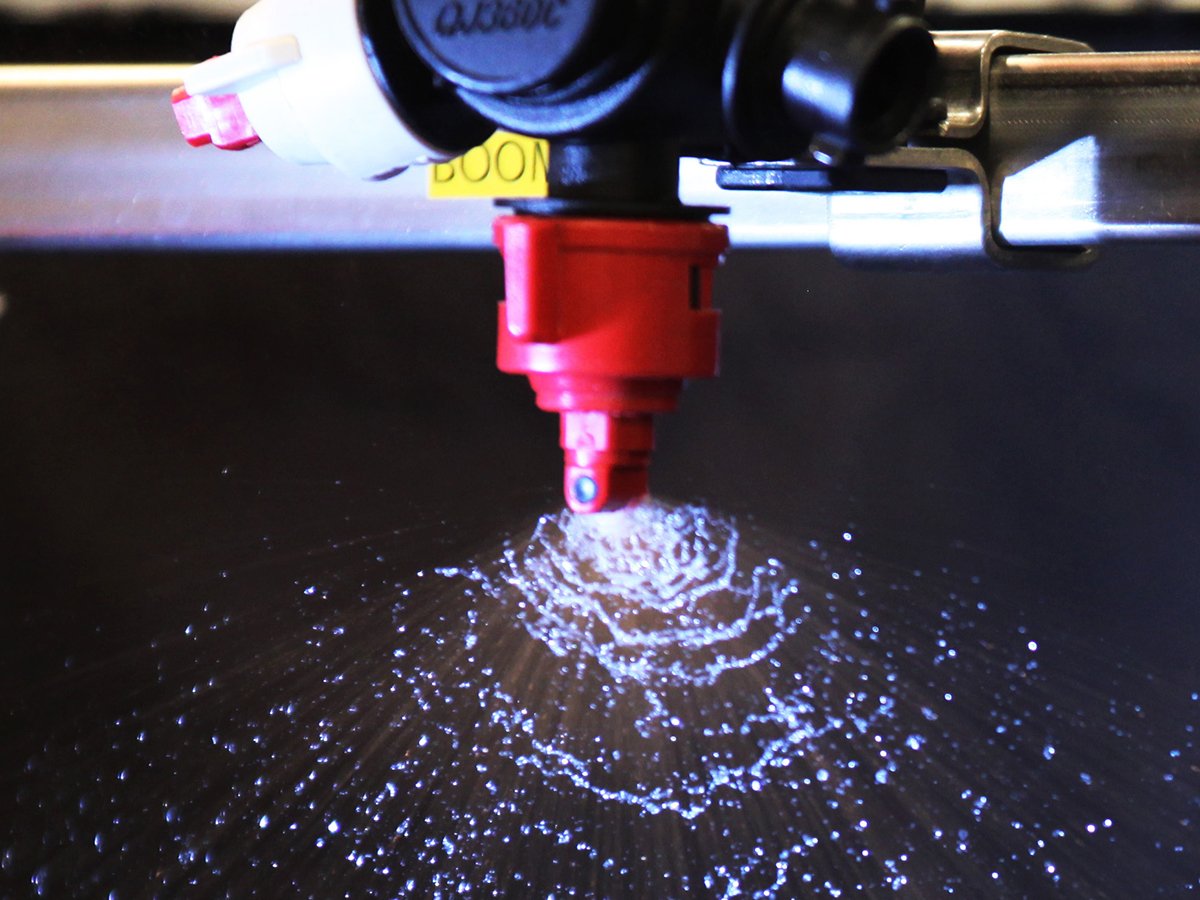

Mechanically, certain ingredients must also be added to canola meal to ensure that the pellets don’t crumble or break during transportation or storage.

Care must also be taken to ensure that the pellets repel water and resist fungal growth.

Fungal growth could impact the integrity of the pelletized product.

“This is not really rocket science,” said Dalai, the Canada Research Chair for Bio-Energy and Environmentally Friendly Chemical Processing at the U of S College of Engineering.

“We just had to create a recipe that can take care of the strength and the density, as well as the water repellent properties.”

Cost of production will be critically important to widespread adoption.

Biopellets produced by the Canadian forestry industry use sawdust as their primary feedstock.

Compared to canola meal, the markets for sawdust are limited.

But if excess supplies of canola meal are available, canola pellets could become an important supplementary fuel source that would reduce Canada’s dependence on other energy sources, such as coal and natural gas.

“Right now, we are the second highest per capita carbon dioxide emitter in the world and a lot of this comes from the (energy) sector,” Dalai said.

If biopellets can be used to complement energy consumption by even one or two percent, CO2 emissions from natural gas or other fossil fuel sources could be reduced by the same amount.

The next step in the process is to demonstrate the economics and functionality of canola-based biopellets.

If that happens, Dalai envisions the eventual construction of a central production facility that would create pellets for use in Canada and abroad.

Investments by government and private sector partners would also help to create a new generation of bio-energy scientists while creating new markets for agricultural bi-products.

“This is just a starting point,” said Dalai.

“The sky is the limit as far as what we can do to complement home heating using organic matter.”