Moose Jaw facility is largest of its kind in the country and will process cull sows and off-spec hogs from Western Canada

MOOSE JAW, Sask. — A new state-of-the-art sow processing plant begins accepting animals this week at the former beef plant in Moose Jaw.

North 49 Foods is a division of Donald’s Fine Foods, which also owns Thunder Creek Pork in the city, and the first major pork plant to be built in Western Canada in more than 20 years.

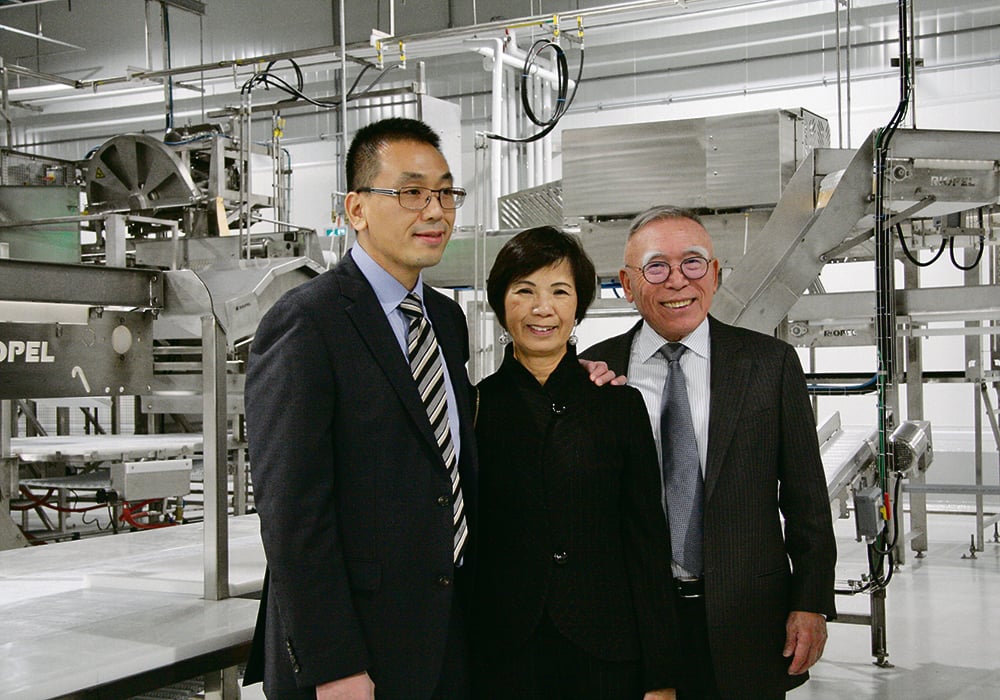

Group chief executive officer Allan Leung said refurbishing the mothballed XL Beef plant in the city’s west end cost more than $60 million.

“To this date it is our largest investment and this plant is also our largest in our whole system,” he said after a ceremonial ribbon cutting Oct. 27.

Read Also

Agritechnica Day 2: The future of tractor power, building quicker crop apps and large farms and tech

Agritechnica Day 2: The future of tractor power, building quicker crop apps with Syngenta and large farms and tech

The largest sow plant in Canada has capacity for 225,000 sows, at 120 per hour, but will take time to build up capacity, Leung said. It will also accept off-spec hogs.

The facility is expected to employ 80 people at start-up and as many as 200 when fully operational. Forty-two skilled workers from the Philippines have already relocated and the company is looking to other countries to fill its requirements.

Leung said the plant uses the latest technology from Europe, including C02 stunning. He said this low-stress method is more humane and results in better meat quality.

A group of animals walk into the chamber on their own and are lowered into a deep well where C02 is applied and they are euthanized.

Most of the industry has converted to this method from electrical stunning, Leung said. In addition to animal welfare, the system is more hygienic and less stressful on operators.

“We are following modern day processing to ensure that we use more computers and more systems to help us make sure that processes run smoothly,” he said.

The products from this plant will be used internally at Donald’s facilities but also by other processors and international buyers.

“In the past a more common usage (for sow meat) is for grinding into sausages. However, with our technologies that we’re employing here and with our knowledge of market hogs, we plan to take whatever we can and market it as table meat as well,” Leung said. “We certainly have a lot of requests from international markets to market the loin, for example. There’s interest in the hams, interest in the shoulder as well.”

Typically, western Canadian cull sows would be shipped to the United States or to a smaller plant in Manitoba. Producers will save in fuel and freight costs and their carbon footprint by shipping to Moose Jaw, plus it will reduce cross-border risks.

Toby Tschetter, chair of SaskPork, thanked Donald’s Fine Foods for its vision.

“This will result in a significant improvement in animal welfare conditions, and reduced cross-border movements will significantly improve biosecurity,” he said.

SaskPork and the provincial government contributed $1 million to a specialized cull line in the plant that could be used if there is a mass casualty event or need for a massive cull because of disease.

“When we go through the border there’s always a chance that there is viruses down there because they may not wash the truck they bring back up to the farm, so we’re trying to improve the biosecurity for the Canadian livestock industry as well,” said Leung.

“Also, if there is some diseases that occur here, such as the Seneca Valley virus, it mimics foot-and-mouth disease and that would cause border closure. By selling locally, that risk is less for the producers.”

Premier Scott Moe said it’s important to be prepared for the worst-case scenario, and the cull line provides an added layer of resiliency for the industry.

Donald’s purchased what is now known as Thunder Creek Pork in Moose Jaw in 2010 and both its facilities will employ close to 500 people.

Leung said they had a difficult time procuring hogs for Thunder Creek at first because of multiple failures from previous owners and managers, but perseverance led to success and a well-known brand in Japan.

The family bought the former beef plant in 2019 to create a better market for cull sows. Leung also acknowledged a $5 million interest-free loan from the federal government, through PrairiesCan, and assistance from the city.

Leung said the company plans to expand on the 100-acre site and transform Moose Jaw into a major food production centre.

Donald’s commemorated its grand opening with donations of $50,000 to the Moose Jaw Food Bank and the Moose Jaw Health Foundation.