Industry observers think a processing plant planned for Saskatchewan could significantly increase acres for the crop

Fababeans have had difficulty gaining traction in Western Canada but could soon accelerate, says a promoter of the crop.

There are signs that the pulse fractionation business could be the much-needed sparkplug.

Until now, demand has been limited for Canadian fababeans in the human consumption market and as an ingredient in hog rations.

“The market has really been the limiting factor,” said Brad Goudy, owner of Faba Canada.

But there is a new source of demand on the horizon.

Goudy is working with C-Merak Grain Ltd., a company from Tisdale, Sask., that plans to build a fababean fractionation plant. The goal is for the plant to be operational in early 2021.

Read Also

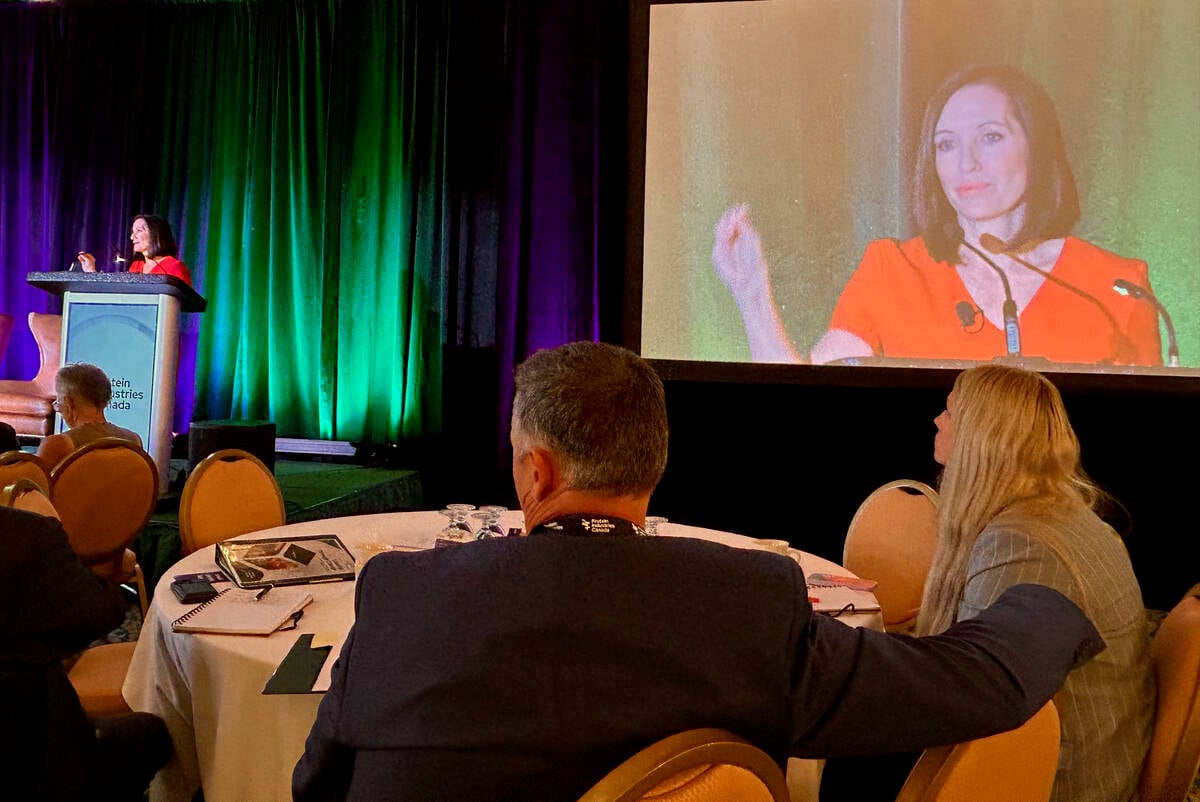

Canada told trade crisis solutions in its hands

Canadians and Canadian exporters need to accept that the old rules of trade are over, and open access to the U.S. market may also be over, says the chief financial correspondent for CTV News.

The facility would process up to 272,153 tonnes of fababeans a year, which would require 200,000 acres of production.

There is also emerging demand for the product from pea fractionation plants.

One of the world’s largest yellow pea processors and a major supplier of plant-based proteins recently stated it is looking to diversify its feedstock.

“We are already looking beyond peas,” Jean-Philippe Azoulay, vice-president of pea and new proteins with Roquette, said in a recent interview with the Global Pulse Confederation.

“Diversifying our sources of sustainable proteins is essential.”

Roquette is building a $400 million pea fractionation plant in Portage la Prairie, Man. The company hopes the plant will be operational in late-2020.

Roquette has been studying the next generation of plant-based proteins for several years to identify the most sustainable feedstock that fits the needs of food processors.

“The fababean is one of them. It is a valuable crop and is a rich source of protein and fibre. Its characteristics will leverage strong food innovation opportunities,” said Azoulay in the Global Pulse Confederation article.

Goudy is already supplying some pea fractionation plants with fababeans, which have higher protein levels than peas and solve another problem.

“They’ve had an issue in peas with taste. Often they can have a strong, not-so-pleasant taste,” he said.

“A lot of food manufacturers have to introduce a masking agent or some kind of flavour to cover it up.”

Fababeans have a more mild and pleasant taste.

There has been plenty of excitement about the crop dating back over a decade. Bert Vandenberg, a breeder with the University of Saskatchewan’s Crop Development Centre, spoke about its potential at Pulse Days 2007, saying it could eventually be a one-million acre crop.

That hasn’t happened. Statistics Canada says growers planted 93,100 acres and produced 107,800 tonnes in 2019.

Carl Potts, executive director of Saskatchewan Pulse Growers, said there is considerable grower interest in fababeans.

“They perform well, particularly in more northern, wetter conditions,” he said.

SPG wants to have at least one economically viable pulse crop option for every acre in the province.

That is becoming more of a challenge as root rot diseases are hampering pea and lentil production in some regions.

It is why SPG is increasingly interested in promoting fababean production in the north and chickpea production in the south.

Potts agreed with Goudy that marketing fababeans has been the major stumbling block.

Egypt buys about 20,000 tonnes of whole fababeans every year from Canada for human consumption. The rest is sold to the domestic hog sector.

Canada has a tough time producing the quality of fababeans that Egypt wants. Growers south of Highway 16 can grow nice, cosmetic beans but the crop yields only about 20 bushels per acre in dry years.

Growers north of Highway 16 are averaging about 60 bu. per acre but their fababeans are only suitable for hog feed.

Goudy believes farmers are capable of rapidly increasing production. He works with about 100 growers, who are each growing about 160 to 320 acres of fababeans.

“As the market develops, I have guys that would jump from 160 acres to 2,000 acres almost from one year to the next,” he said.

If the fractionation demand materializes, Goudy believes there could eventually be two million acres of fababean production in Western Canada. The crop could allow growers to stop growing canola on canola, reducing the risk of clubroot disease.

But for the time being, he is expecting about the same number of acres in 2020 as farmers grew in 2019, unless he hears from the fractionation industry that it needs more.

The big driver of production in the short-term will be the Tisdale plant.

“It might be one more year before we really want to ramp up acres,” said Goudy.