Cleanfarms collects 65 percent of the chemical jugs used on farms, compared to a 94 percent collection rate in Brazil

A 65 percent recovery rate on empty plastic farm chemical containers destined for recycling has spurred Cleanfarms to aim even higher.

It wants to collect and recycle 100 percent of the plastic jugs used on Canadian farms, which would be a fitting celebration to recognize 30 years of voluntary agricultural jug collection.

“A lot of people are talking about zero waste these days, and realistically we have the capacity to collect 100 percent of all the containers,” said Cleanfarms general manager Barry Friesen.

“There is no reason in the world that we couldn’t collect 100 percent of them, and 100 percent of them means keeping all of that plastic in the economy. There’s seven to 10 times more jobs in recycling than there is in landfills…. It’s just the right thing to do.”

Read Also

New coal mine proposal met with old concerns

A smaller version of the previously rejected Grassy Mountain coal mine project in Crowsnest Pass is back on the table, and the Livingstone Landowners Group continues to voice concerns about the environmental risks.

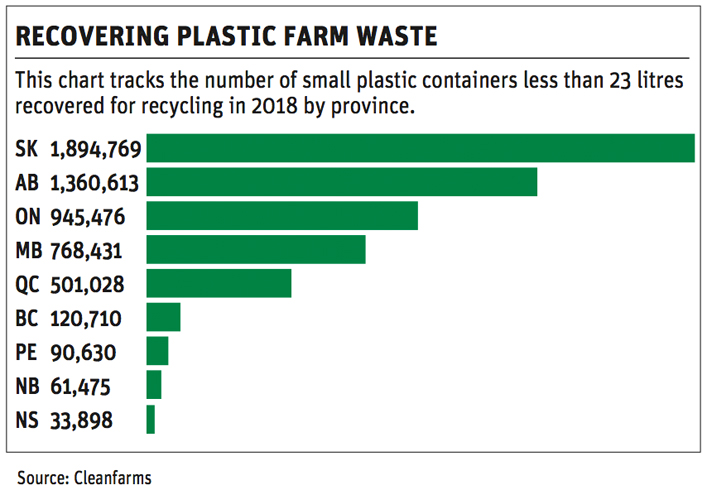

In 2018, Cleanfarms recovered 5,777,030 plastic containers across Canada in sizes of 23 litres or less. That represents a 14 percent increase over the number collected in 2017 and is a 65 percent recovery rate. It’s a level virtually unheard of for a voluntary program, said Friesen, noting the year-over-year increase bodes well.

“We’re well on our way to doing a lot better, and with last year’s increase, we’re really encouraged by it.”

However, Canada still has a lower return rate than Brazil, which recovers 94 percent of its plastic agricultural containers. France recovers about 80 percent and Germany about the same.

Cleanfarms is a not-for-profit organization created by the companies that sell crop protection products, many of which are sold in plastic containers.

The funds received through sale of the used plastics to recyclers do not cover the cost of the program, said Cleanfarms communications co-ordinator Barbara McConnell. However, they do offset some of the program costs. Manufacturers cover the balance as part of industry stewardship.

Since the collection program’s initial creation by CropLife and later transition to Cleanfarms, it has expanded to also collect empty seed, fertilizer and pesticide bags, silage wrap, grain bags, twine and larger pesticide and fertilizer drums and totes.

Materials are recycled to become farm drainage tile, flexible irrigation pipe and garbage bags.

China’s 2017 decision to stop accepting plastics and fibre for recycling had a major effect worldwide. Essentially half the world’s recycling infrastructure abruptly dissolved, and it did affect the Cleanfarms program, said Friesen.

“What we’ve experienced particularly is lower prices when we sell the plastic. We offset some of the costs of the program with the sales of the plastics … and we’ve had to take a bit of a hit on that,” he said.

“However, with sort of an industry-run program, we’re very consolidated. We’ve got good systems in place. We still manage to recycle the plastic that we collect. We’re in really good shape. And I think that’s testament to having an industry-run extended producer responsibility program like this, is that my members have a vested interest to make sure that we can continue to move this plastic.”

McConnell said expansion in the range of materials collected is done carefully. Pilot programs are used to initiate collection of any new products to identify and remove kinks in the process.

Manitoba’s pilot project to collect silage wrap is one example taking place this year, as are other pilots in Alberta and Saskatchewan to collect plastic seed and fertilizer bags.

“These programs are growing all the time, and we are constantly developing strategies … that we deploy in all the provinces,” McConnell said.

Clean material is desired and when it comes to plastic jugs, she said farmers are well versed in the need to triple rinse and remove the cap when returning them to any of the more than 1,000 collection sites across the country.

Friesen said manufacturers do consider recycling options when designing their containers.

“You’ll probably see in the future there’s going to be redesigning of some of these containers to make sure that we can keep this plastic in the economy,” he said.

The sturdy plastics required for agricultural products are also a benefit when it comes to recycling, McConnell added, because they can be turned into a wider variety of products.