In lean times, variable rate technology can help cut costs, but managing land and equipment is essential: adviser

CHICAGO, Ill. — Farmers will need to tighten their belts over the next couple of years as crop prices remain weak, but a consultant says they will need to be smart about it.

Chris Barron, president of Ag View Solutions in Iowa, said the knee-jerk reaction is to reduce inputs such as fertilizer, seed and herbicides, but those are small ticket items for most farms. For instance, herbicides make up five percent of the cost of production for his client base.

Instead, farmers need to focus on land and equipment, which account for 53 percent of the cost of production for his clients. U.S. land tends to cost more than land in the Canadian Prairies.

Read Also

Organic farmers urged to make better use of trade deals

Organic growers should be singing CUSMA’s praises, according to the Canadian Chamber of Commerce.

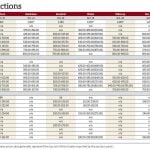

Barron said there is a significant disparity in land and equipment costs among his client base. Land costs range from 90 cents to $1.88 per bu., while equipment costs range from 52 to 97 cents per bu.

That’s nearly a $1.50 per bu. difference between the big spenders and the cost conscious farmers.

“There’s a lot of operations that have cash rents that are too high,” Barron told DTN’s recent Ag Summit 2015 in Chicago.

He said there is often a three-year lag between falling commodity prices and lower rental rates, but growers can successfully negotiate more favourable agreements in the interim by coming to negotiations armed with facts.

He talked about one Iowa client who thought he was averaging 200 bu. per acre growing corn on rented land, while the landowner thought it was higher than that.

Barron sat down with the farmer and figured he averaged 190 bu. per acre on the rented land.

“That’s a pretty significant (difference) when you start looking at an additional $40 per acre (10 bushels) that’s really not there,” he said. “It’s incumbent upon us to have good facts and figures and documentation when we show up to have a conversation instead of talking about the weather for 45 minutes and business for five minutes.”

Barron encouraged farmers to separate their land into thirds based on return on investment. The top third is the farm’s most productive and highly profitable land, while the bottom third is the opposite.

Farms facing diminishing margins might want to consider selling some of the bottom third land.

One client who was farming 12,000 acres averaged $35 per acre for total revenue of $420,000 during the period of high prices.

The farmer downsized to 8,450 acres and averaged $72 per acre for total revenue of $608,400 during a period of lower prices.

Growers can save another $50 per acre by making better use of their equipment or collaborating with a neighbour.

Barron said many farmers overlook the return to management cost, which is the money a farmer takes out of the operation to pay for home improvements, vehicles, vacations and college fees for their children.

That cost ranges from $36 to $226 per acre among his client base, or 18 cents to $1.18 per bu., which amounts to a potential cost savings of $1 per bu.

He also encouraged farmers to consider using variable rate seeding and variable rate fertilizer technology.

Barron calculated a total seed and fertilizer cost savings of three percent using the technology on one Iowa farm. It amounted to $27,948 in savings for the 2,950 acre farm.

That might not seem like a lot, but over 10 years it would save the farm $318,000 with compound interest.

There was also a corresponding yield increase of five bu. per acre, which generated another $9 per acre and $26,550 in revenue for the farm that year.

That would amount to $366,827 in additional revenue over 10 years. Adding the cost savings and the revenue together results in an extra $684,827 over 10 years.

“That might be the difference between this operator staying in business or not or maybe buying the neighbour’s farm or not.”