Merlo recently made its entire range of Roto rotating telehandlers available in electric plug-in versions.

With the main goals of reducing emissions, noise and fuel, Merlo has added an electric motor to the Roto range that can control all its movements, except for forward and reverse.

Following on from the introduction of the eWorker all-electric telehandler, the new plug-in Roto, available as an option on the Roto models, is also part of the Merlo Generation Zero range.

A plug-in power supply system will allow the rotating telescopic handler to be operated at full capacity without using the diesel engine once the machine is positioned for work.

Read Also

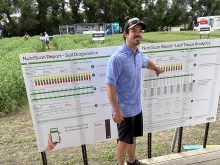

Plant tissue testing key to maximizing crop health and yield: experts

How plant tissue testing plays a vital role in indentifying nutrient imbalances, improving fertilizer efficiency and boosting crop yields

The telehandler’s hydraulic functions are powered by an on-board electric motor, with operation of the Roto available from the cab, the aerial work platform, or by controls used remotely by the operator.

Merlo says the performance of the plug-in Roto is identical to the standard diesel-powered machine, but it has the added benefits of reduced pollution, minimal noise and less fuel consumption without compromising power.

The plug-in Roto is also able to operate indoors, in confined spaces and in areas where only zero-emission machines are permitted. It can operate in diesel mode when travelling on the road, and for positioning of the machine.

Once in position, the Roto can then be switched to plug-in mode by connecting the 50-metre cable to a compatible power source, 400V, 32A or 64A.

At this point, the machine’s stabilizers can be positioned, and all of its hydraulic functions can be activated in electric mode, with the exception of frame shifting.

With the 32A version, the machine’s movements are a bit slower, while the 64A version guarantees movement speeds that are more consistent with those of the diesel machine.

The Merlo plug-in system consists of four elements: control unit, electric motor, hydraulic pump and the 50-metre-long power cable.

The control unit is positioned at the front of the machine’s frame. It contains the electrical system’s indicator lights, start and stop buttons, including emergency stop button, and the power supply type selector to choose between diesel engine of the electric motor.

The three-phase electric motor powers a variable displacement hydraulic pump capable of delivering a flow rate of 70 litres per minute.