Food safety regimes | Producers need to have processes in place to meet buyer demands

TORONTO — Adopting only minimal food safety regimes is a recipe for failure for fledgling food companies, says a food consultant.

Paul Medeiros of the Guelph Food Technology Centre said some producers are looking to do just enough to meet the requirements and audits that many buyers demand.

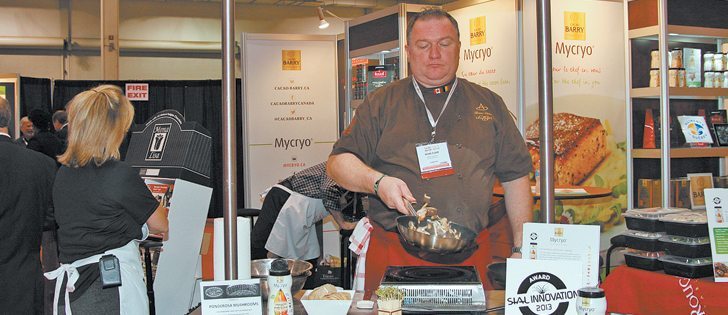

“You’re setting yourself up for failure. You’ve got the wrong attitude right at the beginning,” Medeiros said in an interview at the recent SIAL food trade show in Toronto.

“You can roll the dice and get away with it, but eventually it will catch up to you.”

Read Also

Fuel rebate rule change will affect taxes and AgriStability

The federal government recently announced updates to the fuel rebates that farmers have been receiving since 2019-20.

Small-scale food entrepreneurs often say they don’t have resources and money to invest, but Medeiros said it doesn’t have to be expensive.

“It’s just a matter of understanding and learning basic concepts,” he said. “Fix the problem, fix the process.”

Medeiros said most mistakes come back to who’s in charge.

“Without management skills, food safety skills fall apart,” he said.

He advised taking the time to understand what went wrong, receive input from workers and customers, conduct audits and observe the food production area.

He said retailers are looking for root cause analysis, problem solving, validation and leadership in their suppliers.

Medeiros cited the 1-10-100 rule, which explains how failure to attend to one problem escalates the loss in dollars.

“For every dollar spent on prevention, you will save $10 in internal failure costs, such as reworking or scrapping, and save $100 in external costs, such as warranty and recalls. And if you kill somebody, $100 is a drop in the bucket,” he said.

Medeiros said continuing to make mistakes is not good business. It takes away from focusing on consumers’ demands and staying on top of trends and competitors.

“It just makes good sense to invest in it,” he said of good management practices and processes.

Jennifer Evancio, senior director with the Saskatchewan Trade and Export Partnership, said there is help for producers to set up food safety systems.

In Saskatchewan, the Food Centre can help set up systems such as hazard analysis critical control points, while Saskatchewan Agriculture offers a food safety systems program for meat processors to help offset the costs of doing so, she said.

“It’s an investment that’s more than worthwhile in the longer term,” she said.

The need for it increases as a business goes from local to larger marketplaces, she added.

“It’s not that people doubt the safety of their food from smaller processors,” she said.

“If there are any issues that come forward, they can go back and see where the issues originated.”

The food industry is increasingly asking for these systems to be in place, she added.

“It doesn’t just reflect on food processors but impacts retailers as well,” she said.

“Nobody wants to deal with food safety issues if they don’t have to.”