LOUISVILLE, Ky. — The crowds that crushed around the Fendt 1000 seemed to grow larger throughout the day after the world’s biggest, non-articulated, four-wheel drive tractor was unveiled in North America.

With 500 horsepower and seven foot tall rear tires, the machine appeared from a distance to look not much different from other tractors of its type, unless one thought about how small the people around it seemed.

The reaction of the crowd at the National Farm Machinery show here was similar to what was seen in Europe last fall at the Agritechnica show.

Read Also

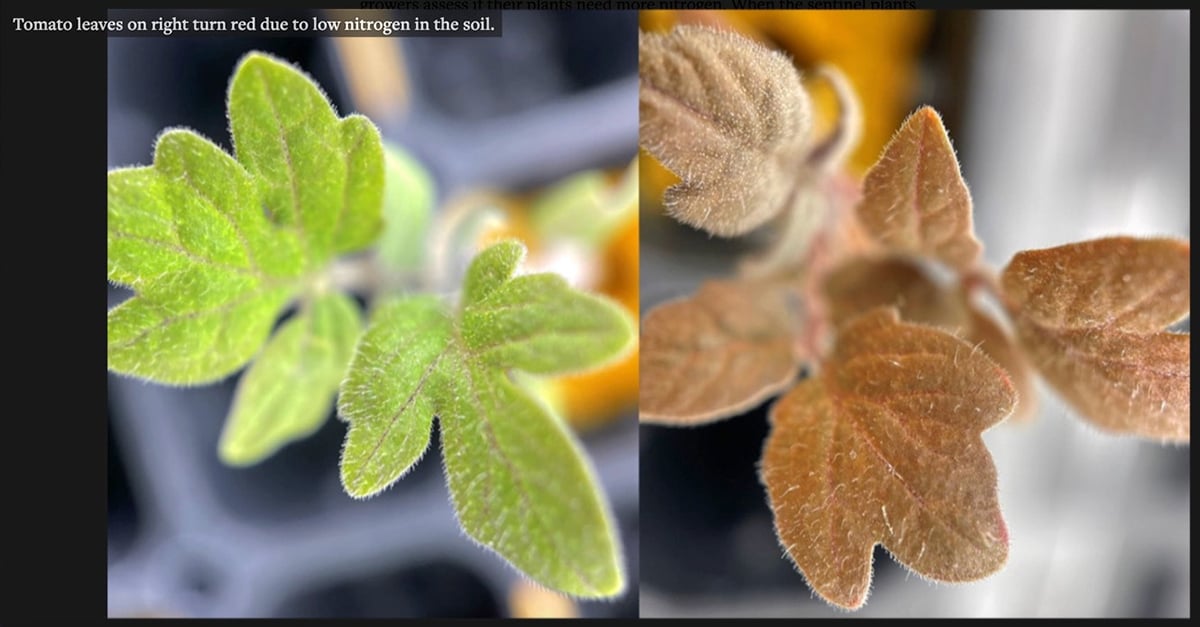

American researchers design a tomato plant that talks

Two students at Cornell University have devised a faster way to detect if garden plants and agricultural crops have a sufficient supply of nitrogen.

The price is in the high US$400,000s, putting it on par with other ma-chines of its capacity.

However, most of the options that one might add to a new tractor are standard on the Fendt, including something its articulated kin folk don’t have — axle suspension.

Stewart Maxwell of Agco’s Fendt said tire choices will be the main option: the machine will take up to triples.

As well, farmers will have the option to choose ballast, which the tractor can load and drop on its own.

It will take the machine from a relative light weight of 30,600 pounds to a heavy duty tillage tool puller weight of 50,700 lb.

The weight is managed by the company’s Vario tire inflation system, which adjusts the impact on the soil as the tractor moves from road to field.

The 12.4 litre MAN engine comes in four horsepower ratings from 380 to 500 and runs up to 1,700 r.p.m.

However, it puts out its most force at 1,100, where it produces 1,770 foot lb. of torque.

The computer systems guide the machine to use the right r.p.m. for a specific job, minimizing fuel burn and maximizing traction. A single pump feels two hydraulic motors, one for each axle.

“The rear axle is fed continuous power through hydrostatic (and) mechanical power splitting. The front axle gets feedback from the rear axle or the four wheel clutches, so the front (axle) becomes part of the power splitting process,” Maxwell said.

“It means each wheel gets power when it needs it, and slip is managed to ensure the power is all used where it is needed most.”

A pair of hydraulic pumps create 113 gallons per minute of flow, and the machine has front and rear three point hitches and an independent power take-off, which allows for constant implement speed, variable engine operation and fuel savings.

“It might take some different thinking on the Prairies to replace an articulated machine with one of these, but when you consider what most of those machines do for about a month a year and what this can do, it can do more than pull a big air seeder and a grain cart, and do it more efficiently,” said Maxwell.

Fendt has suggested that big fixed frame machines offer farmers more trade-in potential and financial flexibility.

“Would it replace a 600 h.p. 4WD? No, not for those jobs that require them,” he said.

“But for most folks, they might ask themselves if that is what they need.”