WINNIPEG — Tom Wolf traveled to Winnipeg in the middle of February to give a talk on the pros and cons of spraying crops with drones.

Wolf, who has 35 years of experience in the spraying business and uses @nozzleguy as his X (Twitter) handle, spent most of his 40-minute talk on the “cons” of spraying with drones.

He’s concerned about the risk of drift from drones and explained, with supporting data, that it’s difficult to get a consistent swath, or spray, width from a drone.

Read Also

New fertilizer product aims to reduce tie-up, improve soil health

A new phosphorus fertilizer, launched at Ag in Motion 2025, promises to reduce nutrient tie-up and deliver slow-release feeding throughout the growing season.

The focus on “cons” prompted a comment from a person in the audience at CropConnect, a crop industry conference held Feb. 12-13 in Winnipeg.

“The title of this presentation was The Pros and Cons of Drone Spraying, but I didn’t hear the first part,” the audience member said.

The comment provoked a smile from Wolf, who admitted that some farmers are seeing value from spraying crops with drones.

Wolf, who hosts and writes for the world’s number-one sprayer website, Sprayers101.com, has spoken with Canadian growers to understand why they like the technology.

“They say no tracks (on the field) and no big bill from my aerial applicator … and I got my fungicide sprayed,” Wolf said.

“There is a logistical reason that these things are popular.”

However, farmers who are happy with drone spraying probably don’t have data on the efficacy of the technology, he said. They don’t really know if it’s better or worse than aerial spraying or using a self-propelled sprayer.

“Let’s go back to the initial question I posed: is this (drone spraying) making things better?” Wolf said.

“That’s really the question.”

Wolf said spraying technologies are evaluated on four criteria: productivity, water volume, spray quality and deposit uniformity.

“Water volume and droplet size are the coverage part of the equation,” he said.

“Deposit uniformity is just the overall quality. Are we doing the same thing on the left, middle and right side of the spray swath, for example.”

Wolf and one of his research colleagues, Jason Deveau, have done experiments in Ontario to evaluate the consistency of drones for swath width and the uniformity of the application.

Deveau is an application technology specialist with Ontario Agriculture.

In an ideal world, as the sprayer or drone travels back and forth across a field, the spray width should be consistent.

“If you buy a 120 foot sprayer boom, how wide is your swath? One-hundred-and-twenty feet,” Wolf said.

“If you buy a T50 drone, how wide is your swath? Nobody knows.”

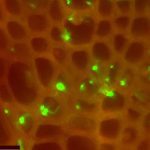

To answer that question, Deveau and Wolf laid a strip of paper across a test field near Simcoe, Ont., and flew a spray drone over the strip.

The tank in the drone contained water with a dye, which becomes visible on the strip of paper.

Deveau used a device called the Swath Gobbler to scan the paper and measure the performance of the drone.

“We can get droplet number and droplet coverage out of it,” said Wolf, who showed the results of those tests during his presentation at CropConnect.

They found that swath width and deposit uniformity are highly inconsistent. It can change as the drone flies over the crop and vary greatly within a few minutes.

The swath width depends on drone height, water volume, flying speed, side wind, headwind, downwind and other factors.

One set of data showed that a professional pilot, flying a drone three metres off the ground at 30 km-h and delivering three gallons per acre, produced three different results in a short period of time:

- Repetition 1: swath width of 21 feet

- Repetition 2: 30 minutes later, 23 feet

- Rep 3: 30 minutes later, 16 feet

“We have variability, even within a short distance,” he said.

“Do not just take someone’s word that you have a 29 foot swath (width). The price of not having a 29 foot swath is striping,” which is duplicating spray on the same strip of crop.

Wolf is also worried about the increased risk of drift from spraying with a drone. Then, there’s the possibility of accidents with other aircrafts and injuries to humans.

A lack of regulations is another issue.

“Anyone here can buy a drone today and fly it this afternoon,” he said.

“I think we’re playing with something that is inevitably going to go south.”

Wolf concluded his talk with some optimism on how the technology could evolve.

Right now, most of the spray drones on the market were developed in Asia for application on small farms. Those drones aren’t suited for a 9,000-acre grain farm in Saskatchewan. Canadian producers will need larger drones, specifically designed for broad acreage crops.

Those drones are starting to enter the market, Wolf said.

“I would say we’re at the very beginning of the drone story for spraying.”

Contact robert.arnason@producer.com