Prairie farmers are sitting on 4.7 tonnes of last year’s canola and may wonder how high temperatures are affecting their binned oilseed.

Wayne Clews has been selling bin monitoring systems at his Red Deer business since 1996, dealing mainly with the Bin-Sense brand built by Calian Agriculture in Regina. Clews handles all four Bin-Sense technologies, each of which provides a different level of grain protection.

“I’ve seen this situation a few times over the years. We get high ambient temperatures. We check the bin walls with the hand-held and it looks not too bad. Temperature along the steel wall is at least acceptable for the moment. What you don’t know is whether or not canola in the centre is starting to heat,” Clews said.

“Grain is a great insulator. Some people don’t understand that. Grain will insulate wall temperatures from centre temperatures. It takes a long time for actual temperatures in the middle to reach the outside walls. That’s why checking the walls can’t tell you what’s cooking in the middle,” he says.

Clews said it takes a lot of solar energy beating on the south bin wall to bring winter-cooled grain up to dangerous temperatures. But hot spring weather can do that.

Grain temperature in the upper end of the single digits and lower teens cooled down over winter. He says leave it for now, but don’t forget about it.

“Now that might fly in the face of what the real experts say, and I don’t consider myself a real expert. The real experts tell us to keep a certain differential between your outside temperatures and inside temperatures. I never really bought into what they say about that. I’ve always valued the cold temperatures we carry over from winter. I’ve never seen grain spoil from being too cold,” Clews said.

“But I’ve sure seen grain spoil from being too warm. When you’ve got 35 C ambient temperature, you don’t want to be blowing that hot air into your grain. I feel it’s an affront to the grain. Winter remains our friend. Don’t ruin the friendship by blowing in hot air. Personally, if the ambient temperature is 35 C, I would do nothing. But some people really like to run their fans.”

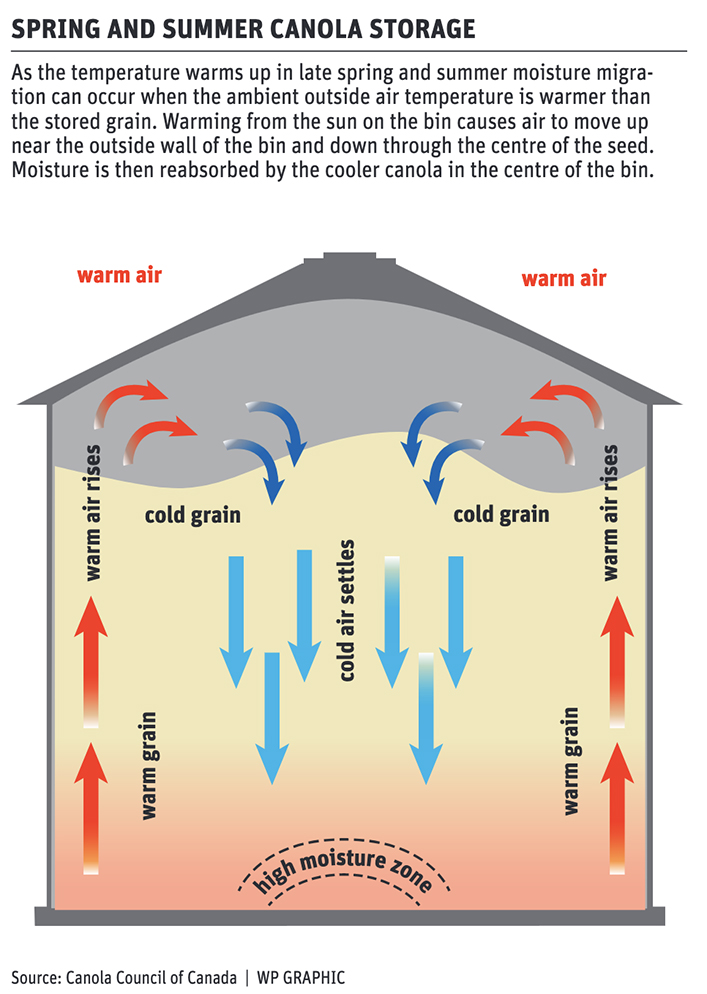

What about temperature differential? Clews says if you get a big differential between ambient temperature and grain temperature, that’s when you might get convection currents. He concedes that convection currents are bad. As air moves, so does the moisture.

Consider canola at 10 C, with daytime air temperature at 35 C and nighttime at 20 C. Clews says running the fans for eight hours overnight might redistribute some of the cold stored in there. He says you might do some good.

“Every farmer knows if you’re not certain how your grain is doing, it’s a good idea to take a load out and inspect it. Maybe move it to another bin. Ideally, you’d want to sell it.”

He points out that at this time of year, farmers have a lot of redundant bin space already cleaned out, fumigated and sitting idle.

It’s easy to split a 12,000 bushel bin into three or four smaller bins for easier management. Clews says the big hang-up is that farmers are too busy farming in June.

“In all our years doing this, we’ve seen that most of the grain spoilage could have been prevented. The losses occur because the farmer wasn’t even aware his grain was heating. He had not been going out with his simple hand-held.

“Keep in mind that if it’s 35 C outside the bin, it’ll be 34 C on the inside of that 12-gauge galvanized steel wall. No matter how great the condition of your stored grain, it’s never so good that it doesn’t require management.”