Whether canola should be straight cut or not is a complex question.

Some answers have been found through research by the Wheatland Conservation Area agricultural producers group based at Swift Current, Sask., said Bryan Nybo.

“Canola is a difficult crop to straight cut due to shattering. And as the price increases along with input costs, the benefits to reduced labour and machinery use have to be weighed against getting the most canola you can from the plant to the bin and protecting your investment in that crop,” said Nybo, an agronomist for the group.

Read Also

VIDEO: Green Lightning and Nytro Ag win sustainability innovation award

Nytro Ag Corp and Green Lightning recieved an innovation award at Ag in Motion 2025 for the Green Lightning Nitrogen Machine, which converts atmospheric nitrogen into a plant-usable form.

In the group’s study, three combine header systems were used. These were a straight cut draper header, a Shelborne Reynolds stripper header and a Biso header extension on a traditional, straight cut header.

The study used three crops: brassica juncea, Argentine canola and oriental mustard.

Stripper headers have become popular for their high harvest capacity that reduces the amount of plant material that feeds through the combine.

However, the system leaves lots of tall stubble that some growers find challenging to handle in reduced or zero tillage systems.

The stripper uses sets of fingers, mounted to a rotating octagonal drum, to remove seed pods and grain heads from plant stems.

It fared the worst in the brassica trials due to higher than acceptable losses of the small oilseeds.

“We think this has to do with vigorous shaking of the plant (by the stripper header). With its pods spread widely across the whole plant, seeds are shaken loose before they reach the combine,” Nybo said.

“The stripper header design seems to perform best in pulses, other than peas, and in flax and cereals where the seeds are concentrated in one region of the plant.”

The straight cut, draper header also had its share of losses, however the tests showed it to be much better than the stripper header, with only 25 percent of the losses of the stripper type.

The draper header’s main losses occurred in the cutter bar.

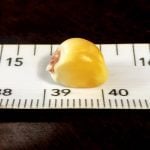

Even better than the draper header was the Biso extension. It sets the cutter bar forward 45 centimetres, attaching it to the header with a stepped platform.

With the header reel also set back 45 cm from the cutter bar, due to the extension, seedpod shattering is reduced.

Any shattered seed is captured by the stepped platform and fed into the combine along with other harvested material. Because canola branches out from the main stem, plant feeding is not an issue at the table.

Losses from straight cutting, using the Biso extension, were minimal in each year of testing, beating the draper system by four bushels per acre in 2006 and three bu. in 2007, said Nybo.

“It’s very similar to swathing, or maybe slightly better,” he said.

The savings over swathing come from reduced machine operation, labour and improved harvest season timing.

“The Biso installs over the existing header and once installed the first time, they say takes 20 minutes to reinstall. It took me longer as I wasn’t used to it, but I can see how it might take 20 minutes with practice,” he said.

“At $19,000 it’s an investment that would pay for itself with average canola prices, grown on 200 acres, in about 10 years.

“More acres, faster payback,” Nybo said.