CHURCHBRIDGE, Sask. – In 2002, Warren Kaeding was looking for a better seed treater. Around that time, a seed company from Delisle, Sask., had secured the rights to a polymer coating called Protec.

The company had designed a treater for the coating and was looking for interested dealers.

“They called us, we looked at it, we said we needed a better treater and this would be the way to go,” said Kaeding, who operates Wagon Wheel Seed Corp. near Churchbridge.

Kaeding built a stationary seed treater in his yard, which is capable of applying the polymer coating to pulse seed or standard fungicidal seed treatments to cereal seed.

Read Also

VIDEO: Green Lightning and Nytro Ag win sustainability innovation award

Nytro Ag Corp and Green Lightning recieved an innovation award at Ag in Motion 2025 for the Green Lightning Nitrogen Machine, which converts atmospheric nitrogen into a plant-usable form.

He uses belt conveyors in and out of the treater and calibrates it ahead of time to determine seed flow rate.

“Once we know the flow rate of the seed, we calibrate the flow rate of the product to make sure the two are matched. Then we’ve got a big Chem-Handler system with a couple of pumps on it: an RV pump that pumps it into the treater and a septic pump that moves the polymer or the chemical in from 150-litre to 1,000-litre units.”

The products are measured into the Chem-Handler and blended using one of the pumps to provide agitation and mixing. The liquid material is then applied to the seed as it drops from a hopper into the mixing chamber.

“The inoculant sticks on to the wet seed, then it goes through a big hex tumbler, about 10 feet long,” Kaeding said. “As it’s tumbling, the polymer and inoculant gets mixed and shuffled around, so by the time it comes out the other end, it’s uniformly coated. At that point, it drops onto another belt conveyor and it’s loaded into a bin, truck, container or whatever we’ve got set up at the other end.”

The treater can process about a tonne of seed per minute, which dries on its own. However, Kaeding said he can’t apply the polymer coating if the air temperature is too low.

“We did find that the seed temperature has to be at least 5 C or greater. Last year we pulled some cold seed out of the middle of a bin and the polymer looked like oil and water.”

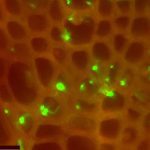

The Protec polymer coating can be used in any pulse crop that needs to be inoculated with rhizobia bacteria.

It is a standard, non-sticking peat inoculant and the polymer coating keeps it close to the seed, which improves longevity of the inoculant for up to 30 days.

“Normally when you put this peat inoculant on, it survives for about 48 hours in the soil. Then it starts to die off,” Kaeding said.

“We’ve done 95 percent of the work with peas and about five percent with pinto beans. We’re not in lentil country and last year, I was in such a panic to put in our soybeans that I didn’t take the time to do it. But those would be options, as well.”

He said the polymer coating is a sucrose-based starchy material that feeds the bacteria in the inoculant as well as protecting it from the soil elements.

“Being that it’s a sugar base, it doesn’t take a lot of moisture to start the breakdown process. It takes a bit of imbibing soil moisture and it starts to release and the seed takes on moisture, as well. We haven’t seen any concerns with germination.”

The coating provides a hard shell, which Kaeding said can help prevent the seed coat from breaking after it has been treated.

“Last year (2005), with the incredibly poor seed condition we had from the frost, hail and everything in 2004, we treated all our pea seed with a seed treatment as well – with Apron Maxx. We were able to put that in with the polymer coating. We put JumpStart in with it. We slurried up a heck of a cocktail and treated everything that way.”

While it was no problem with these specific products, Kaeding said some products will reduce storage and planting time for treated seed.

“It’s not a cheap process. It costs about the same amount as what a granular inoculant costs. But once a guy has tried it, we found most of our previous customers are asking for it again, for two reasons: convenience and they do see an actual difference in the field.”

Kaeding charges by the bushel and this year his retail price is $3.75 per bu. on peas, which includes the polymer coating and the inoculant. Any seed treatment is extra.

“There’s lots of polymers coming down the pipeline,” he said. “This is just the first generation of polymers and I believe there’s a lot of interesting stuff coming. It could be polymers in cereals, pulses or oilseeds that will make a real difference, so I’m hoping I’m on the leading edge of technology.”