Sow barns in Canada are steadily being converted to group housing systems from gestation stalls as producers respond to food company and animal welfare group demands.

A website developed as part of the National Sow Housing Conversion project is designed to provide producers with information needed to convert their barns or build new ones using group sow housing systems.

The website has a straightforward address: groupsowhousing.com.

It was launched in early January with information outlining conversion options, cost estimates and examples of how farms have converted to open sow housing or built new barns incorporating it.

Read Also

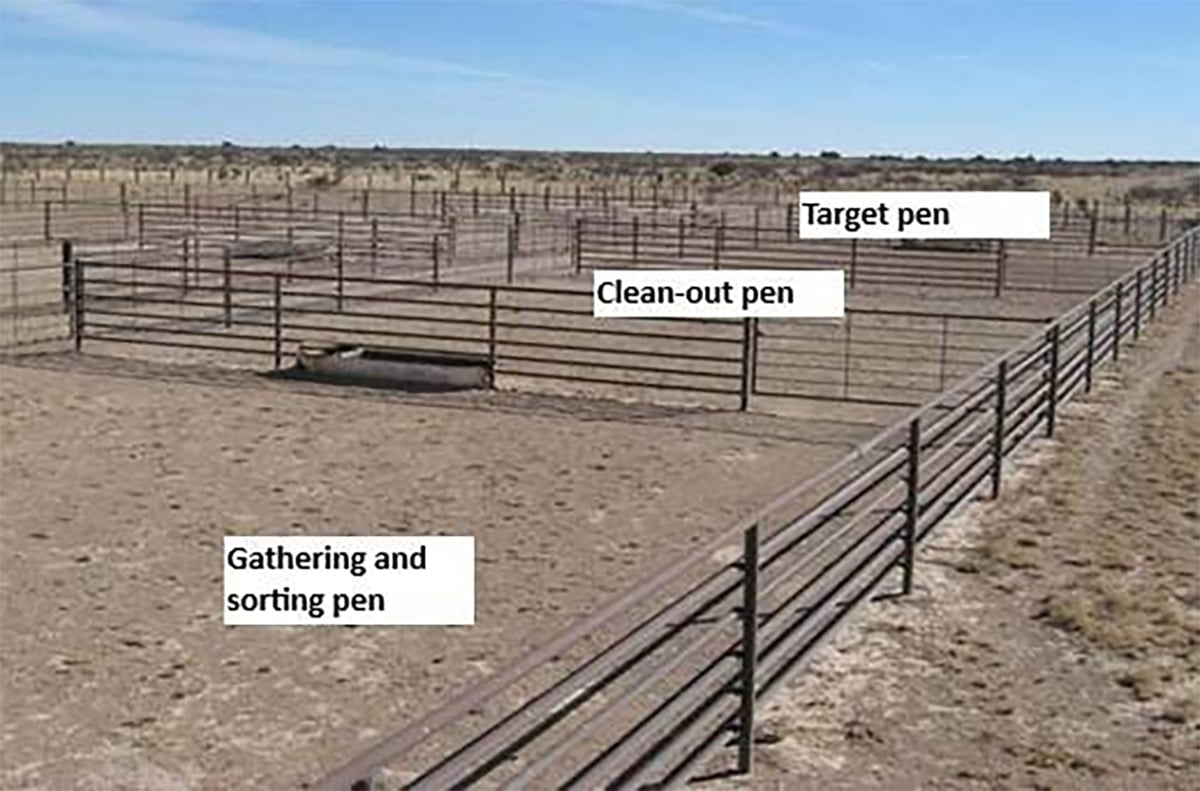

Teamwork and well-designed handling systems part of safely working cattle

When moving cattle, the safety of handlers, their team and their animals all boils down to three things: the cattle, the handling system and the behaviour of the team.

Dr. Jennifer Brown, a research scientist at the Prairie Swine Centre near Saskatoon, said few barns in Western Canada have been converted to open sow housing, but the process is much further along elsewhere.

“In Western Canada, we haven’t seen a lot of conversion, and a lot of that is because we have much larger sites. We have much more large integrated producers,” said Brown.

“We do see a large number that have converted in Quebec because they do take advantage of a lot of those niche markets and they’re certainly ahead of the game across the country.”

The national Pig Code of Practice requires that sow operations undergoing renovations or building new barns must incorporate group housing for sows.

Operations that use sow stalls and maintain them will be allowed to continue with that method, but the code requires that sows in those systems be given additional opportunities for exercise as of 2024.

Brown said there is little science on how that can and should be done. The result is that producers who continue to use gestation stalls and individual housing will eventually be at a disadvantage.

Every sow barn is slightly different, said Brown, so the website has compiled the best science on how to manage sows in groups and includes information from producers who have successfully managed the transition.

Brown said the goal is to find more producers who will allow their conversion to be documented step by step so others can observe and potentially apply it to their own operations.

“I really wanted to have a number of sites that we would document from the beginning to the end of renovation, and those have been hard to find,” said Brown.

“I’d like to get four examples, and right now I have three and one of them is actually a new build.”

The website has information on types of feeding systems, grouping strategies and sow and gilt management in open housing.

It also gives information on relative costs of different open systems, including electronic sow feeding (ESF) systems and a new free access ESF system developed in Canada that has been popular in Quebec.

Brown said she was surprised that in many cases barn conversions have been cheaper than expected, at much less than $500 per sow. A University of Manitoba study estimated costs of $800 to $1,000 per sow.

By gathering information now, Brown said producers could be in a better position to make the conversion when it is most economical, such as when hog prices drop or if they want to depopulate a barn for herd health reasons.

“The more you’re prepared up front, the more you can take advantage of economic situations like that,” she said.

That was the case with Red Deer area hog producer Wim van Wijk of Horst Farms.

He converted his 275-sow farrow to finish operation in 2013 over an eight-week period at an estimated cost of slightly more than $250 per sow.

Van Wijk did most of the work himself and built one large ESF pen that holds 168 sows. He replaced slatted floors and created a bedroom area with concrete pads for greater sow comfort.

On the new website, van Wijk is quoted as saying the conversion has improved production, piglet mortality and ease of farrowing. It has also made the sows calmer.

The Matador Hutterite Colony near Swift Current, Sask., is also featured on the new website.

It opened a new 600-sow barn last year that uses a bank of ESF feeders in sow group gestation pens. There are separate pens for gilts and sows.

Fact sheets available at groupsowhousing.com cover topics such as competitive feeding, free access stalls, ESF and free-access ESF.

There are also links to a site that estimates costs of barn conversion, which was developed by Manitoba Pork and the U of M.

barb.glen@producer.com