Bin SumpPro neutralizes threat from sump plugs that block the grain-flow, causing farmers to venture inside

South Dakota grain grower Shawn Gengerke said a plugged bin sump three years ago tried killing him, not once, but twice. Adding insult to injury, the incident cost him US$15,000.

“That was when I decided we had to put an end to this plugged auger problem that’s killing and maiming farmers every year,” said Gengerke last week.

“We had a big 100,000 bushel bin plug on us. We had to get in there and break it loose. In addition to the money it cost, the bin tried killing me twice that day. It was a close call.”

Read Also

Growing garlic by the thousands in Manitoba

Grower holds a planting party day every fall as a crowd gathers to help put 28,000 plants, and sometimes more, into theground

That was where the idea for his Bin SumpPro originated.

“I decided that day that we’re never ever getting into a bin again, and we haven’t. We have close friends who’ve had family members die. The tragedy is all around us. It happens every year.”

Gengerke explained they had to cut a hole in the bin. But with the size of today’s bins, you can no longer simply cut a hole in the side. He first had to build an auger tube that could be pushed into the bin at least 18 feet so they could unload from the centre of the grain load. There’s always the danger that the bin could tip if the load isn’t drawn down evenly.

“It’s very easy to have a bin tip on you, especially these bigger bins. That wasn’t a factor with those little 3,000 bushel bins we had 30 years ago. You cannot unload these bins from the sides.

“So we wrecked the door, wrecked a panel, built that auger tube. We tried everything to get that grain out; air and vacuum. It cost $15,000 to unload 100,000 bushels.

“It’s a foolish problem for us to still have today. It’s an age-old issue. It’s taken too many lives. We designed this thing with one thought in mind. This is a tool for saving lives.”

Gengerke is a farmer first and inventor also first. His innovation company, Leading Edge Industries, has two other products he has displayed at Manitoba Ag Days in the past. The Load Judge is a system for determining load in a grain trailer. The Harvest Sweep for corn heads is designed to put more corn in the tank. All three products are produced in his own factory or in the immediate area.

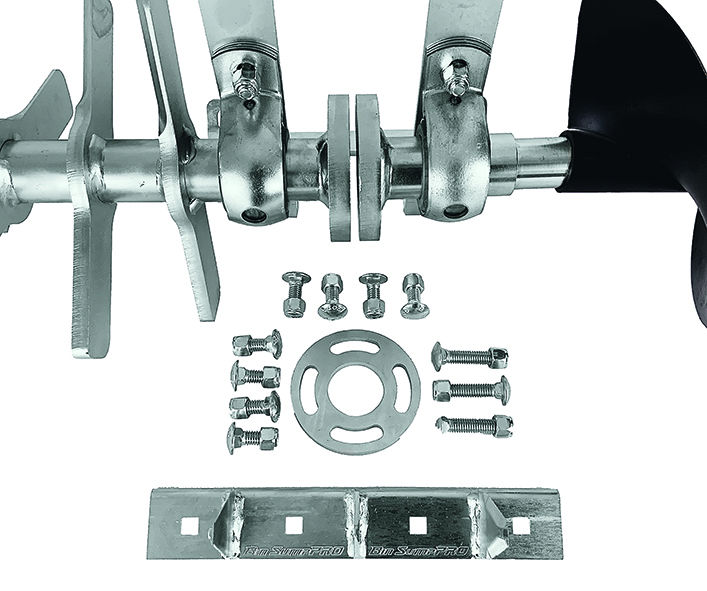

He said Bin SumpPro is a two-part process for breaking up clumps that would normally plug the sump. First, it breaks up all types of clumps and ice above the floor with a beater that retrofits to the power sweep system already in the bin. Second, it cuts and clears material lodged between the top of the floor and the discharge auger under the floor.

“The beater is what chews up the plugs. Even with that beater working so well, we need a counter-measure in case a chunk does get caught in between the top of the floor and the bottom of the floor. We have to clear those.

“To handle that, we have a secondary attachment that goes on the gate of the sump itself. You can manually control that to make it run back and forth to dice up those chunks. It’s attached to the gate controller.

“If you don’t need it, you don’t use it. Honestly, in two years of testing in all kinds of bins, I don’t think we’ve ever had to use it. The beater does everything it needs to do. We run it a short time, then everything keeps flowing.”

Gengerke says they’ve run it under a full 125,000 bushel bin. It starts cutting clumps even with that much weight bearing down. The machine is built of AR400 steel, which is an abrasive-resistant alloy, and it’s zinc plated. It has no problem chopping granular fertilizer to make it flow. He has tested it throwing blocks of ice into the bin and it chews them into bits suitably sized for martinis.

The Bin SumpPro has not yet been stumped by any flowable product and Gengerke said it will handle 99 percent of all flowable products.

Combining these two innovations is a game changer in grain bin safety.

Bin SumpPro was designed in response to situations that force farmers into bins, including immature crop, excess moisture and high humidity conditions. These conditions create sump lodging.

Every year, families are devastated by grain bin accidents that originate from a plugged bin sump. As well, thousands of dollars are spent unplugging or cutting holes in bins to remove the grain, a dangerous practice.

Bin SumpPro is a retrofit kit for grain bin sweep systems. It uses the existing powerhead, gearbox and a modified auger, allowing it to run under full compaction load.

The system is compatible with any grain bin with a floor sweep system. Bin SumpPro lists for US$3,950.