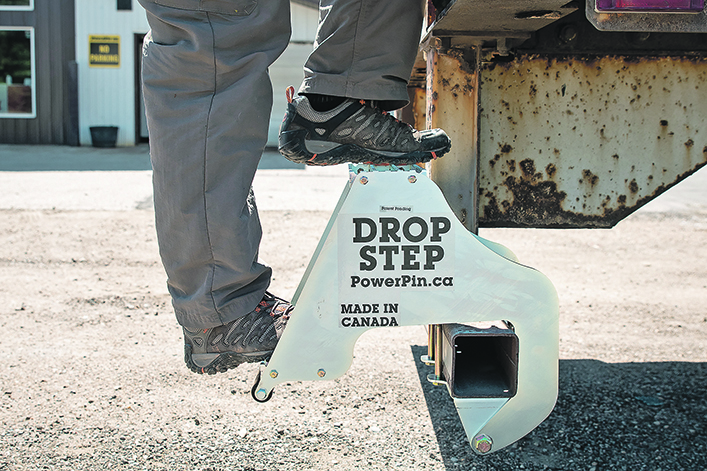

Brian Olson is the owner of PowerPin, but that doesn’t mean he’s above driving the company truck.

In fact, he drove that semi between Fort Qu’Appelle, Sask., and Winnipeg for 10 years.

His main Winnipeg destination didn’t have a loading dock. That meant hundreds of ups and downs into the van over the years, a part of the job that was irksome, and sometimes dangerous in winter.

“I think I was about 270 (pounds) at the time so climbing into that trailer was just plain terrible. Getting out was worse, fishing around for the bumper with your foot. So I had to figure out a way to put steps on that bumper,” says Olson, who is known as the inventor of PowerPin drawbar hitches.

Read Also

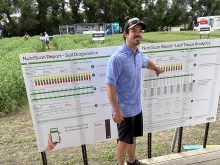

New fertilizer product aims to reduce tie-up, improve soil health

A new phosphorus fertilizer, launched at Ag in Motion 2025, promises to reduce nutrient tie-up and deliver slow-release feeding throughout the growing season.

“When we made the first one, the pivot point was on top the four-inch bumper, so you had to flip it up manually. And it worked fine, but to commercialize it, we knew it’s only a matter of time before a driver forgets to flip it up, and at his next stop he’d back into the dock and smash it. I think we made 10 Drop Step prototypes,” he said in a phone interview.

“I’ve been in this business long enough to know that you have to make these things idiot-proof, and it wasn’t idiot-proof yet. Then after about three years, we had that eureka moment and we moved the pivot point so it was under the bumper. Now if you backed into something, it pushes the steps up and forward into travel mode. Now it almost worked, except that the loading dock had too much friction, so it wouldn’t ride down and under the bumper. We added a roller so the steps slide along the dock wall until it drops into transit position. Totally idiot-proof now.”

Olson says there are 10 million semi-trailers on the road in North America, plus another 300,000 added annually.

In an email conversation, Olson said, “We sold our Hit-N-Hitch On-Road to Curt (Manufacturing) in the U.S.A. because they have the distribution to take it to the U.S. market quickly. However we will not be selling the Drop Step to another major outlet. They’re 100 percent made in Fort Qu’Appelle.

“We plan on bringing a lot of U.S.A. money back north. Consider how much Canadian farmers spend on Deere and Case tractors and combines. We need to bring some of that money back. PowerPin supplies 13 tractor plants around the world, so we’re working on bringing some of that cash back to Canada.

Drop Step will fit any trailer, cube van or flat deck that has the mandatory four-inch bumper. There are other potential uses on tongues of agricultural implements where the operator wants a safer way to get up to service a machine. Olson says flatdecks that haul sprayers are another market.

The Drop Step is less than 13-inches wide. It requires 11.5 inches from top of bumper to bottom of the deck. In travel mode, it requires 16.5 inches of space in front of the bumper under the deck. It has a grated step that provides a nonslip surface. Ultimate down load strength is more than 1,200 pounds. DropStep sells for C$250.