Grain dryer sales have been red hot but growers tend to be as late as their crops in placing orders for the machines, say a couple of retailers.

Jim Kelley, vice-president of sales with Flaman, said the company didn’t sell dryers until two years ago when it started handling Neco dryers.

Sales increased 10-fold between the first and second year.

“We’re very bullish on dryer sales for the next five years,” said Kelley.

“We see it as a major part of our business going forward.”

Read Also

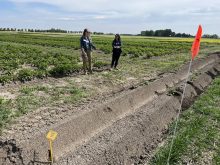

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Jayde Klassen, grain dryer sales and service technician with Wentworth Ag, believes sales of the company’s GSI dryers are up more than 10-fold year-over-year.

He believes it has a lot to do with the recent stretch of wet weather conditions.

“In all my years of doing this, I’ve never seen falls like the last two,” said Klassen. “The demand for dryers is huge during the tail-end of the season.”

Harry Brook, crop specialist with Alberta Agriculture, said until 2016 many growers had dryers from the 1970s and 1980s that they weren’t using.

But that year more than one million acres went unharvested on the Prairies, piquing farmer interest in modern grain dryers. A few wet falls since then have exacerbated that interest.

“(Farmers) get fed up having to wait and be on tenterhooks for so long,” said Brook.

But he noted that buying a grain dryer is a big investment. The machines can prove invaluable in a year like this but not every year is like this.

“The sheer variability of our weather means that it’s not something that will pay for itself every year,” he said.

And it’s not just a one-time expense. In addition to the sticker price, there is the annual operational costs of running the machines.

“You’re throwing more money into these grains and oilseeds,” said Brook. “I just keep thinking, where do you draw the line?”

More and more farmers are deciding it is worth the investment.

Klassen just wishes growers would do more long-term planning rather than making snap decisions. Orders that come late in the growing season place stress on farmers, retailers and gas providers.

“It’s very time-consuming getting everything hooked up and looked after,” he said.

“To make sure it’s all done properly, it takes a while. It’s not just a snap of a finger.”

Dryers need to be built on a concrete pad, which can take time to arrange.

Farmers need to know what kind of natural gas supply they have and how much volume the dryer requires. It can take months to arrange for natural gas and weeks for propane.

Power is the other big consideration. Dryers may require single phase or three phase power. A lot of farmers don’t have enough service to run the machines and are instead opting for power generators.

There are a lot of details to take care of, including inspections, which is why Klassen prefers to sell the units in the winter and set them up in the summer.

“If you can get started on the project sooner, do it. You’re going to kick yourself if you don’t,” he said.

Kelley said farmers are increasingly approaching dryer purchases as long-term investments rather than “panic” buys.

His best sales pitch is that dryers allow farmers to get into their fields a week earlier than normal.

“I always say a week of harvest at the end of August is like two weeks of harvest at the end of October,” he said.

The days are longer, the temperatures are higher and the conditions are typically drier.

Dryers keep grain from spoiling and help maintain grades.

“The risk is too great to have thousands and thousands of bushels of high-priced grain in a bin and not look after it,” said Kelley.

“A grain dryer is an investment in peace of mind and quite frankly better grades at the elevator.”

But it is a big investment. Flaman’s dryers range from $100,000 to more than $500,000. The small ones can dry 300 bushels per hour while the big ones can do up to 5,000.

Flaman targets farms of 5,000 acres or more and has lots of customers in the 25,000 to 100,000 acre range.

Wentworth sells smaller units targeted at the 3,500 to 4,500 acre operation.

“The hot sellers are right around that 400 bushels an hour mark,” said Klassen.

Some of his customers have found a way to help offset the cost of buying a dryer.

“A lot of guys are entertaining the idea of custom drying for neighbours, making a little bit of side cash doing that,” he said.