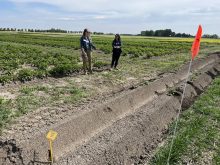

LANGHAM, Sask. — Other than Ag in Motion, where can you see 10 air drills and planters in a side-by-side comparison? As expected, the pocket knives came out after each drill made its premier pass.

More than 30,000 farmers gathered at AIM over the course of three days in July, and those farmers attending the demonstrations weren’t disappointed.

As long as they stayed behind the yellow ropes, they were able to get up close and personal while each manufacturer did its best to impress the crowd with how it solved the challenges of precise seed and fertilizer placement and field finish. And, as they say, the proof was in the pudding when the knives came out.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

For those who missed the show, we bring you this review of the 10 drills.

Bourgault

The 3320XTC (eXtra Terrain Contouring) features enhanced contouring capabilities for fields where terrain changes are sharp and numerous.

The 1:1 contour ratio of the opener assembly delivers good contouring because the full parallel linkage allows the XTC opener to follow the field independent of the frame. The packer wheel and seed opener travel in unison for precise results. Placement depth will not be affected if the frame wheels sink in soft soil. The distance between the seed opener and packer wheel is very short, helping achieve consistent seed placement even with sharp changes in topography.

Concord

Concord brought its Precision Shank Drill, which it calls a blend of the old Concord with modern technology.

Competing with the new compact disc drills, the Concord seeds at speeds up to nine m.p.h. with good field finish and good residue clearance. Row units independently follow the ground contour.

Down pressure, frame height and shank tip pressure are controlled from the cab. Individual rippled coulters slice trash and fracture the soil surface. Independent closing discs capture the soil displaced by the openers.

The drill is available in 51 and 61 foot widths and is available with a variety of seed and fertilizer openers from different companies.

Horsch

Canola growers were intrigued by the Canola Ready Technology on the Maestro SW 3115 on 15-inch spacing.

Horsch says it has the highest level of precision for seed depth and singulation in the industry. Growers report cutting their seed rates in half with no yield reduction, using the SW.

Handling each seed individually rather than through a controlled spill reduces seed mortality, and each seed is placed at a uniform depth. Producers typically plant 350 to 500 acres per day with their Maestros.

John Deere 1870

The 1870 independent shank machine is available in working widths of 40 to 67 feet.

The openers are designed to allow independent downforce on each shank, thus creating more uniform depth across the entire width of the frame. Deere says the openers have good residue clearance and individual opener monitoring.

The 1910 cart ranges from 195 bushels to the 550 bu. unit on display, which had scales on each of the four tanks.

Morris

The 40-foot Morris Quantum demonstrated at AIM uses a new joint welding process that’s 154 percent stronger than conventional methods.

The new Barsi Air System uses stainless steel flat fan dividers to distribute seed and fertilizer gently and accurately with low row-to-row variances. The large outlets reduce plugging.

The Quantum was demonstrated with Shieldcore paired row openers, which place seed two inches on either side of a centrally located fertilizer band three-quarters of an inch below the seed. The 9 series air cart is made of stainless steel.

Flexi-coil

Flexi-coil says its 7200 Precision Hoe Drill parallel link opener maintains opener depth from the top to the bottom of the links range.

The new cam depth adjusters take less than five seconds per opener to change. It is a no-tool one-handed adjustment, ranging from zero to two inches.

Calibration of the 60 series cart is managed by the calibration wizard built into the Flexcontrol display. Sectional control is standard, with automatic control as an option.

New Holland

The P2082 Double Shoot Disc Drill uses parallel link openers to provide uniform seed to fertilizer placement across the entire drill frame at speeds up to eight m.p.h.

The Flexi-coil P series cart has individual seed metering control for improved accuracy.

It was introduced five years ago as a single chute drill, but the demand for single pass, double chute accuracy and speed led the company to develop the second run technology. The result is a side-band shelf for the seed and a fertilizer run an inch lower and to the side.

The machine is built as wide as 60 feet and will feature higher field speeds.

Its capacity will rival much wider shank-type tools, and with single pass fertilizer placement has advantages to planter-type tools. However, it does not possess seed singulation.

The 18-inch discs are on 10-inch row spaces. Seed depths range from half to two inches, and a lightly treaded packing wheel closes the seeding trench, leaving a crease for improved cracking in heavier soil.

Pillar

Located north of Saskatoon, Pillar is a relatively new manufacturer, concentrating on further development of hybrid disc/hoe openers.

The Pillar Hybrid Disc/Hoe opener places seed and fertilizer with a single opener in one pass. It has 1.5 inch vertical and approximately 1.25 inch horizontal separation. The vertical separation can be adjusted as the disc wears down.

The Disc/Hoe creates a firm, clean seed bed. The seed boot carves the seed bed, which eliminates hair pinning.

seed bed width is approximately 1.25 inches wide so seeds are spread across the whole area for better swath support at harvest time. The opener producer provides just a bit of disturbance to give the field a black ribbon to warm up the seed bed.

Pillar started making the DH-4010 disc/hoe machine in 2008.

SeedMaster

The Ultra SR is accepted as the most advanced, fully integrated, large acre air seeder.

The company uses its dual knife opener along with Ultra-Pro II electric drive metering for seed and fertilizer. The drill at AIM was 60 feet wide with a 735 bu. cart. Tanks mounted on the tool bar frame transfer weight to the tractor for extra traction. A single rank tool bar is possible because of the innovative residue management system, which uses rotating spoked wheels to clear residue to the side.

Seed Hawk Vaderstad

The Vaderstad TPL 24 660 merges the technology of the Seed Hawk iCon air cart with the singulation, speed and precision of the Tempo planter.

The company says it gets good placement at speeds up to 10 m.p.h.

The TPL 24 planter is set up on 18-inch row spacings. A Capstan liquid system is installed for seed-placed pop-up fertilizer. For the AIM demo, the rig was planting canola at a rate of 2.5 pounds per acre while placing fertilizer at a rate of 100 lb. per acre.