Train braking system needs to be re-thought

Recently there have been three train wrecks that resulted in spectacular smash-ups of rail cars. The first, near Saskatoon, thankfully did not result in loss of life, even though two locomotives and 30 cars derailed at a level crossing.

In the Kicking Horse Pass, sadly three train crew lost their lives. My sincere sympathy is extended to their families.

In these incidents, there is now great puzzlement over the cause of these wrecks. Since the Lac Magantic disaster 5 1/2 years ago, nothing has changed with respect to rail safety. There is no mystery: simply put, trains have no brakes.

Read Also

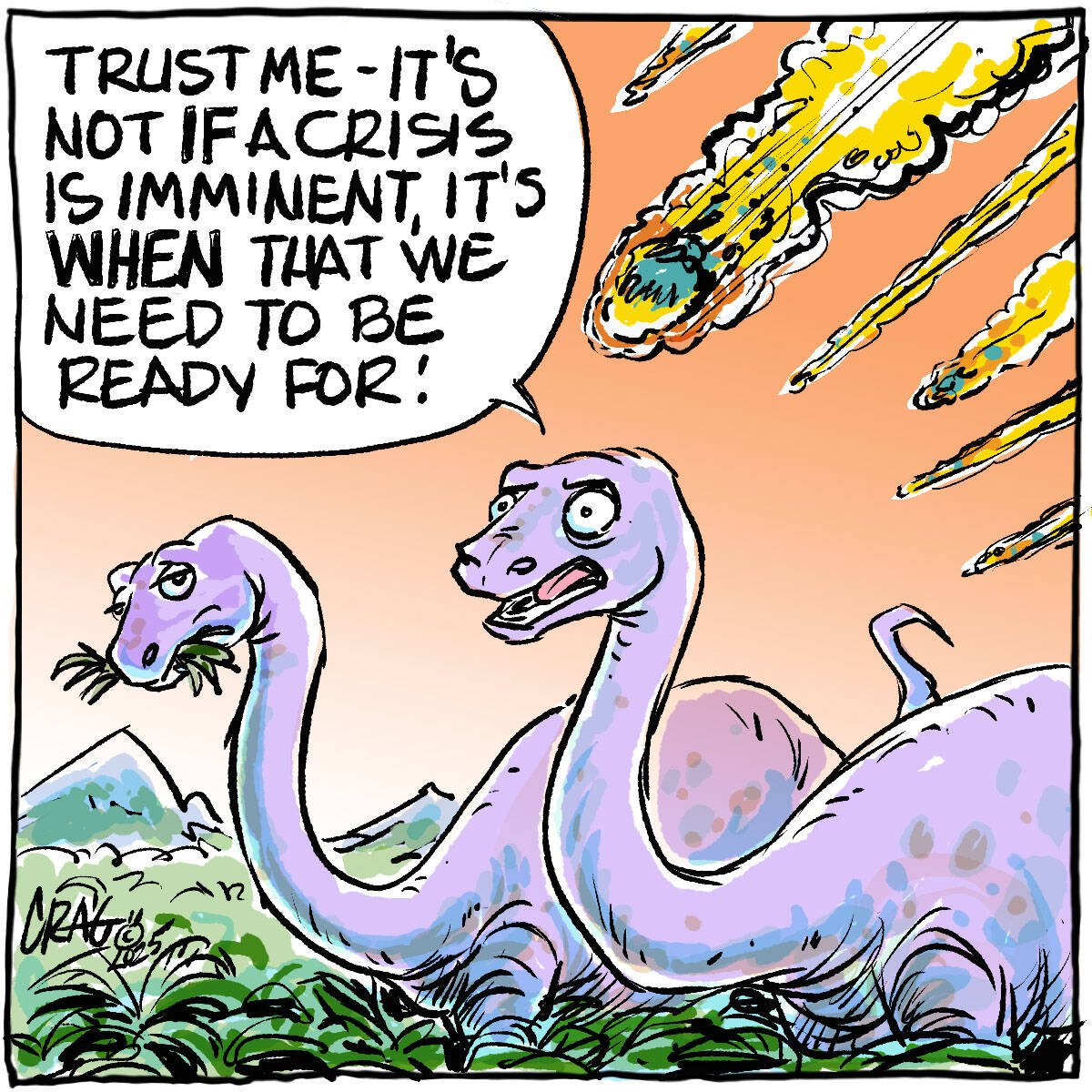

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

The air-brake system they use is virtually unchanged since it was invented by George Westinghouse in 1868.

As designed, they were capable of controlling the small trains of the day powered by steam engines hauling a few cars. The present system is woefully inadequate.

Here are the facts: train brakes are operated by the single air line system that is about 1.5 inches in diameter that runs the length of the train, often more than a mile. The area of the brake shoes on a standard 100 tonne grain car is about one sixth that of a standard 18-wheel semi that carries 30 tonnes. The weight of a loaded grain car is at least three times that of a semi. That means a semi has about 20 times the braking power as compared to a train.

Train brakes are barely capable of holding a car when it is stopped, let alone do anything to stop it when in motion. Trucks also have — and this is just as important as the brake capacity — spring powered brakes that are automatically applied in the event of air loss for any reason. This means that trucks must have a safe level of air pressure to release the brakes and allow the truck to move. This system of brake control is long overdue for trains. It has been mandatory for trucks for about 50 years and needs to be adopted by railways right away.

This system would stop runaways caused by not applying hand brakes. With spring brakes, the engineer can instantly apply parking brakes from the cab. In the event of derailment and resulting air loss, the spring brakes would slow the oncoming cars and prevent or reduce the spectacular pileups.

As it is now, the only thing that eventually stops the train is the size of the pile of wreckage.

Critics will question if what I say here is true, how do trains operate as safely as they do? Trains have the right of way — all others must get out of the way or suffer the consequences. Train tracks are constructed to be as level as possible with two percent grade max, unlike highways where hills are rarely considered in their design.

The main braking takes place through the locomotives. Since they are diesel-electric, massive braking is performed by reversing the drive motors. This only fails when the weight of the train overcomes the traction of the locomotive.

Trains are among the largest and heaviest machines that humans construct. For context, a 112-car grain train, loaded, weighs 15,000 tonnes. The engines have a weight of 600 tonnes. That is a ratio of 25 to one. Clearly the locomotives cannot control the train safely without adequate brakes.

An alarming aspect to the rail scenario is the prospect of an additional 7,000 oil tank cars. Can you imagine the mess 112 oil cars dumped in the Kicking Horse River would make?

Unless swift, concrete action is taken to ensure railways modernize their brake systems, expect to see more wrecks — not if, but when.

I am calling on Marc Garneau, minister of transport, to convene a panel of rail engineering experts to find ways to address this problem.

Donald Voss

Spiritwood, Sask.