HAYS, Alta. — Power pole number 6663136 stands along Highway 36 north of Taber, Alta., holding up an array of electrical wires.

The lodgepole pine pole is 35 feet tall with a circumference of 32 inches. It was placed in its spot in 1994 after being treated with chromated copper arsenate (CCA), a wood preservative. A testing crew checked this pole in 2008 and again in 2015 and injected it with a fumigant to prolong its use.

“It’s a good pole, from here,” said Bill Hoskin, area co-ordinator for Fortis Alberta, as he checked the data on the laptop in his pickup truck.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Details like those for pole 6663136 are available for each of the 1.1 million power poles owned by Fortis — power poles that are so common on the Prairies that they are scarcely noticed, except by those who must farm around them.

Less common is knowledge about how these poles, vital to electrical service, are tested, maintained and preserved.

Related story:

Last fall, two power poles owned by ATCO, another electricity provider in Alberta, broke and fell over in high winds near Acadia Valley. They started one of many wildfires that wreaked havoc in the province’s dry-as-dust southeast quadrant.

Results are pending from investigations into that situation, but it raised questions about pole care and maintenance.

Fortis agreed to help answer those questions in terms of its own program. The company covers the widest range among Alberta providers and thus is responsible for a lot of poles — the aforementioned 1.1 million, plus many owned by Rural Electrification Associations.

Crews will inspect an estimated 150,000 poles this year.

On this day, Hoskins was checking on pole-testing crews working near Hays, Alta. He does spot checks on about 50 crews working in the province.

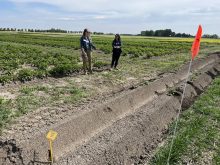

A crew consisting of Dave Remanda and Kevin Okoh had started the day at 5:30 a.m. to beat the heat but29 C temperatures by 11 a.m. had them sweating as they dug around the base of pole 7183070 (a 40-foot cedar pole placed in 1985) to examine its state.

“This ground is super hard,” said Remanda as he and Okoh dug the rocky soil. “And man, it’s hot.”

“Feels like home,” quipped Okoh, a Canadian university student originally from Nigeria, who is pole testing for the summer.

The two men work for Integrity Pole Inspections, one of the companies sub-contracted by Fortis.

“Pole testing is a specialized discipline that’s best contracted out,” said Hoskin. “We’re looking for the most cost-effective way of getting the work done.”

These seasonal crews are not the ones who climb poles to check lines and connections. No, they’re the ones that dig below the soil surface, or as Remanda puts it, “we’re the bottom feeders.”

Remanda is one of several certified pole inspectors who work for Integrity. That means he has tested or helped to test 5,000 poles with another certified inspector before gaining his own designation.

In Fortis’s program, poles are tested every seven years, starting from about 15 years after initial installation. Until then, poles generally get only visual inspection, said Hoskin.

After about 15 years, inspectors dig around the base of the pole to expose about 50 centimetres below ground level. They drill several holes to gauge its shell thickness. They also inject a fumigant that kills insects and fungus, and then plug the drilled holes.

At the next visit, pole inspectors will remove the plugs, test the shell thickness again and administer more fumigant.

Then they wrap the exposed lower pole in paper covered in metam sodium, a compound that penetrates the wood cells and further inhibits fungi and insects.

Hoskin said it costs an average of $2,500 to replace a pole, and that cost can vary dramatically depending on pole location. Those on rocky hillsides or in soft ground might require specialized equipment, for example, so it’s cost-effective to protect poles already in position.

Poles can also be reinforced with stubs, which are U-shaped metal channels that extend pole life.

Most Fortis poles in rural areas are cedar or lodgepole pine.

“Generally cedar is for our bigger poles, so (the ones that are) longer and bigger around,” said Hoskin. “We’ve tried different species. These do work well and are readily available.”

The poles are treated with either CCA, which is green, or pentachlorophenol, better known as “penta,” which is brown.

Poles are put into the ground to a depth that is 10 percent of its length, plus two feet, said Hoskin. For example a 40-foot pole goes six feet into the ground and a 90-foot pole goes in 11 feet.

“That hasn’t changed with metric,” he joked.

Metal and fiberglass poles are also used but wood is preferred for most situations because poles can be ordered to fit the need and can be climbed by linemen without need for special equipment.

Given heightened awareness about rural crime, testing crews are required to inform landowners of their presence. Hoskins said they are expected to visit farmhouses and explain their planned work, or leave a note if no one is home.

He recalls one incident when a pole inspector was greeted at the door by a woman holding a shotgun, raising concerns all around.

But in most cases, farmers and ranchers are aware of crews and accepting of their need to access land.

That’s been Nick Berger’s experience. He is director of field operations for Integrity.

“Our interactions with farmers are, I would say, 99.9 percent of the time pleasant. Almost always pleasant. You can’t please everyone,” he said.

“They’re usually quite happy and very warm to receive us. Some people are even overly generous. We were at a gentlemen’s house just outside of Purple Springs last week and he wouldn’t let us leave without pop and chocolate bars. And not just one.”

Berger said he’s aware of concerns about rural crime, which is why his workers drive white service trucks with company decals and beacons so they look professional.

However, that’s not the case for all of Fortis’ sub-contractors, some of whom use their own vehicles and some who work alone.

Hoskin said the inspectors carry identification, letters with a brief description of their duties and office numbers that landowners can use to verify identities.

“We try to make sure that the customer is consulted before we enter,” he said.

Farmers themselves have been known to strike or topple power poles with equipment, though Hoskin said that is not as common as it once was.

Bigger modern farm equipment creates some problems because a lot of older pole placements were made when implements were smaller and there was a greater tendency to string power lines via the shortest distance rather than along road allowances.

“My dad farmed with 12- and 14-foot equipment and there’s nobody that farms with less than 20 feet now,” said Hoskin. “Farming equipment is getting to the size now that it’s a lot different from when we first started putting poles in.”

Farmers who damage poles are generally expected to pay for replacement if it’s needed, said Hoskin. If the pole is old, depreciation might be taken into account.

But accidents happen.

This season a farmer pulling an air seeder took out wires and poles in the Eckville area, said Hoskin, leaving customers without electricity for about six hours.

In a much more serious recent case, a Wetaskiwin area farmer was unsure whether the bins he was moving would fit under the lines between the poles. He raised a tape measure toward the line, and lost both his lower legs from the resulting electrical force.

Pole inspectors don’t handle electricity but they face other hazards. One crew working in Kananaskis country had to forego testing when a grizzly bear buried a partially decomposed elk along the line. They also have to contend with adverse weather and a wide array of ground conditions.

“It’s hard work in that nothing is ever the same,” said Berger. “No two poles are the same. There’s always a challenge, there’s always variables.

“Sometimes we have good soil, good conditions, good access. Other days we’re hiking through mountains and pulling rocks and gravel out of poles and removing bushes. We’re always challenged from each day to the next, but there’s always a solution. That’s the best part about it.

“It’s a blend between art and science, the whole thing.”