Producer designs gauge to provide real time readout of flow rate while drying grain with an aeration fan

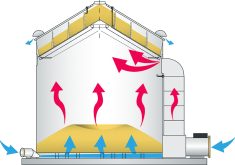

BRANDON — If you don’t know the airflow rate in a bin, you have no idea whether in-bin aeration drying is working. The result could be a bin full of spoiled grain.

If you have real-time airflow readouts as you’re augering in, you can fill to the optimal level to get good drying with any fan you’re running, says farmer Glenn Wilde of Wilde Ag Ventures in Cudworth, Sask.

Wilde has developed a simple device he calls the Static Pressure Based Air Flow Indicator. He emphasizes that the instrument is not a flow meter.

Read Also

Growing garlic by the thousands in Manitoba

Grower holds a planting party day every fall as a crowd gathers to help put 28,000 plants, and sometimes more, into theground

Instead, it’s an indicator to be used in conjunction with the manufacturer’s fan curve that’s appropriate for individual fans. An actual flow meter is a much more costly instrument.

“Any time you’re doing in-bin grain drying with an aeration fan, you need at least one (cubic feet per minute) airflow for every bushel of grain in the bin. That’s the minimum. On our farm, we typically run up to 1.5 c.f.m. to be safe,” said Wilde.

“There’s no easy way of knowing your flow rate, unless you measure static pressure and you have your fan curve handy. That lets you look up the flow rate on the chart. All we’re doing is combining the gauge and the fan curve chart. Now you actually have a direct real time readout of your flow rate while you’re filling the bin.

“It’s most critical when you’re trying to dry small canola or flax seeds because there’s so little space between them. You really have to be careful the column doesn’t become too high. Instead of trial and error, our system puts a little science into the process.”

The face of the gauges Wilde displayed at the recent Manitoba Ag Days show in Brandon has three scales for quick reference:

- The inner blue line reads inches of water from zero to 10.

- The middle red line reads c.f.m. for a five horsepower Edwards #80511 Grain Guard.

- The outer red line reads c.f.m. for a three h.p. Edwards #80311 Grain Guard.

Wilde has only calibrated the system for those two fans, which are commonly used on the Prairies.

He will custom calibrate gauges for any fan on the market at no extra cost to the customer.

He would need the manufacturer to provide him with the engineering specs.

Once he has that information, he would design and install a face plate specific to that fan.

Wilde has only installed his gauges on smooth-sided hopper bins. He said producers drill a hole through the side downstream from fan outlet to mount the gauge and thread in the self-taping stem.

The gauge remains installed for the life of the bin. He hasn’t installed any gauges on corrugated bins yet.

The gauge has a list price of $35.

For more information, contact Wilde at 403-803-6092 or email wav@shaw.ca.