The compost has to be screened and tested before the compost is offered for sale to the public

A large-scale composting project at Yorkton, Sask., is diverting millions of litres of canola waste from the city’s landfill and turning it into a valuable commodity.

The city just hasn’t figured out what to do with it yet.

Participants at a recent compost field day heard that municipalities and organizations looking to start large-scale composting should take one critical step before they start: visit Yorkton.

Larry Mullen, the Saskatchewan Waste Reduction Council’s master composter, says the east-central city’s project is a prime example of how projects should work.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

Every community will have a slightly different system, he said, but “Yorkton is the poster child.”

Michael Buchholzer, Yorkton’s director of environmental services, said that’s likely because the program doesn’t cost the city anything and contributes to the goal of zero waste to the landfill by 2025.

The project began in 2008 when the SWRC offered funding for large-scale composting programs.

“At the time we were a little unsure but we thought it fits in our mandate of our environmental committee,” Buchholzer said.

A small trial project began, using flax straw from golf course winter greens cover and manure from Heartland Livestock, which is within city limits. The city also removes biosolids from its lagoons during the winter and had to do something with them.

“It took a little while longer to break down (because of the flax straw) but all in all it turned out to be a really good product,” he said.

At the same time, two canola processing plants were announced for the city and both had large landfill requirements for waste seed products, dockage, oil and food grade wash water.

“A little five round bales of composting went into roughly now 80 to 100 acres of composting,” Buchholzer said of how the project has grown since the two processors began operating.

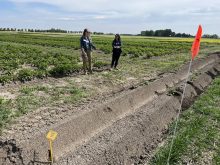

The site now includes 40 to 50 rows of compost, each about the length of half a quarter section. At the base, each row is about three metres wide. The rows are initially about two metres high but shrink by half as they compost.

Heartland supplies the manure, the nitrogen source required to make compost work, and the canola plants pay to haul their processing waste to the site. The wet product from the processing facilities helps keep the piles moist, although the wet weather of the past few years has helped.

Buchholzer said it is actually cheaper for the plants to haul to the compost site than to dispose in the landfill. The project is making money now, although the city’s goal is to break even.

None of the compost has been sold yet.

Compost offered for sale must be screened to remove contaminants like heavy metals and tested for things like salmonella and E. coli. It is subject to Canadian Food Inspection Agency regulations.

Yorkton has asked the Composting Council of Canada for help on how to proceed.

Residents are able to add their yard waste to the site, free of charge, but Buchholzer said few take advantage of that opportunity. A household collection system is not planned.

The city would like to sell the compost to residents once testing has been done. It won’t be bagged, because of the regulations, but likely sold by truckloads.

Buchholzer also said contractors have approached the city about purchasing compost for housing developments. Only one has said clients are willing to pay $100 per cubic yard.

“A lot of their clients are saying they want weedless dirt,” he said. “Every piece of dirt in Saskatchewan has canola in it. Everybody’s fed up with that. We’ve experimented in a few yards and you almost could advertise it as weedless.”

The composting process, which can reach temperatures of 65 C, essentially burns all the weed and canola seeds in the product.

Buchholzer said he has been trying to convince the city’s public works department to use the compost in boulevards and other city property.

However, it won’t be free, even for another city department.

“I think they understand it’s worth using a better product and incorporating that cost as just a cost and that’s it,” he said.

There are costs to making compost. The site is staffed and equipment is needed to turn the piles and monitor temperatures. There will also be testing costs.

Meanwhile, the city doesn’t see an end to the material coming into the site. In 2014, it took in 30,874 cubic yards of total compostable material and estimates 90 percent of that came from the canola plants.

Buchholzer said that amount would require a single landfill pit each year just for the plants.