Big equipment is exciting, but it’s the technological ad-vances that have the potential to fundamentally change the way we farm.

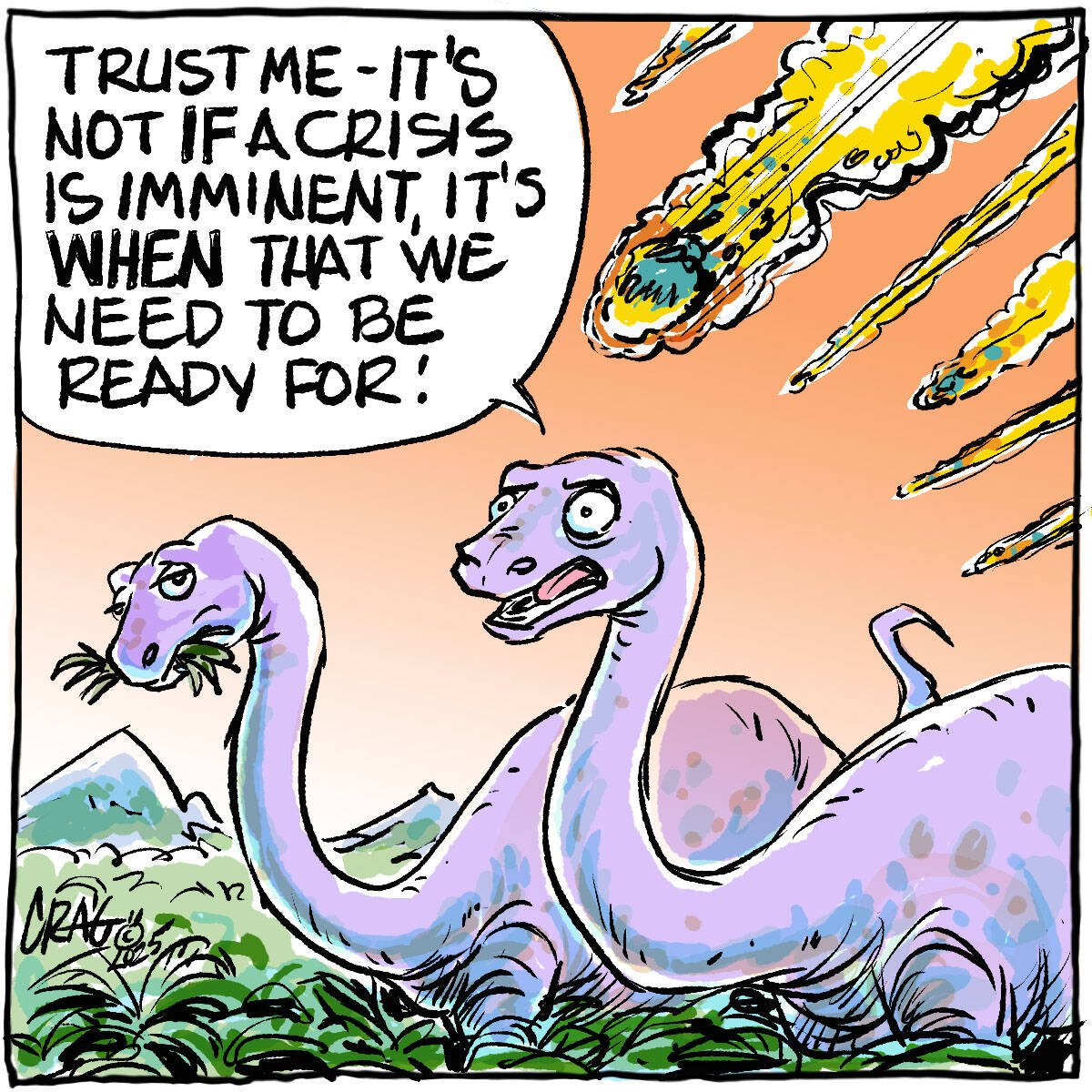

Agritechnica, which is held every other year in Hannover, Germany, is the largest farm equipment show in the world. Impressive machines are everywhere from dozens of tractor manufacturing companies that most of us from Canada have never heard about. Some of the big high clearance sprayers look as if they’ve been modelled after the dinosaurs in Jurassic World.

However, some of the booths also feature technology that’s a potential game changer.

Read Also

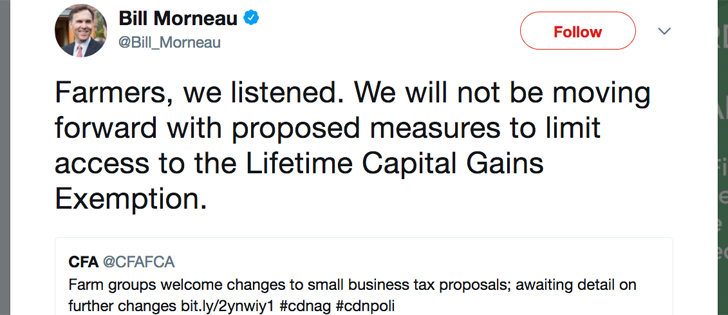

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

That’s the case with Deepfield Robotics, a Bosch start-up company. Bosch is huge with more than 300,000 employees worldwide. Deepfield Robotics is a nimble little start-up launched in 2014 with only 20 employees, but it has the backing of its parent company.

Deepfield is working on robotic applications for crop production, but the one that captured a lot of attention at Agritechnica was the Deepfield Weeder. It stamps out weeds in a crop and avoids the use of herbicides.

The robot is programmed to de-tect plants that look different than the crop. As well, the weeds are not in standard spacing in straight rows like the crop, which also aids in detection. Guided by accurate GPS, the robot passes over the crop and little plungers stamp on the weeds.

Roland Tschakarow of Deepfield Robotics said it isn’t the force that’s important. Instead, it’s the acceleration of the plungers. If the little weed isn’t killed, it’s certainly set back and offers far less competition to the crop.

Of course, the system works only when the weeds are small, and it wouldn’t work if you have a mat of weeds. The first application for the technology is high value crops such as vegetables, particularly for crops that are grown organically.

The initial machines have a limited capacity. It takes three hours to cover two and a half acres. Of course, that varies depending upon the weed count. The unit has to slow down if there are a lot of weeds.

The individual aspects of the technology are not revolutionary, but putting all the pieces together in a system that will work under field conditions is remarkable. Deepfield will be testing the system with organic farmers next year.

A system covering 60 acres in 24 hours may not seem like much of an option when a high clearance sprayer can cover thousands of acres in a good day, but the technology should be scalable by making it wider or using more robots.

The overriding issue will be cost, which will determine whether the technology will someday be feasible for field crops in Western Canada.

It wasn’t too many years ago when most of us thought hands-free GPS guidance was a pipe dream. Now it’s the norm. Most of us couldn’t imagine going back to doing all the steering manually.

Herbicide resistance is a rapidly increasing threat. A targeted system of mechanical control looks attractive in the absence of chemical solutions to weed control.

Relatively lightweight robots can run even when the field is wet. Windy days wouldn’t be a problem. Plus, they will be unmanned, requiring only supervision.

Technology has continually surprised and amazed. The high clearance sprayers of today may indeed be the dinosaurs of the future. Machines that are increasingly bigger and faster certainly have appeal, but they may eventually lose out to machines that are smarter.