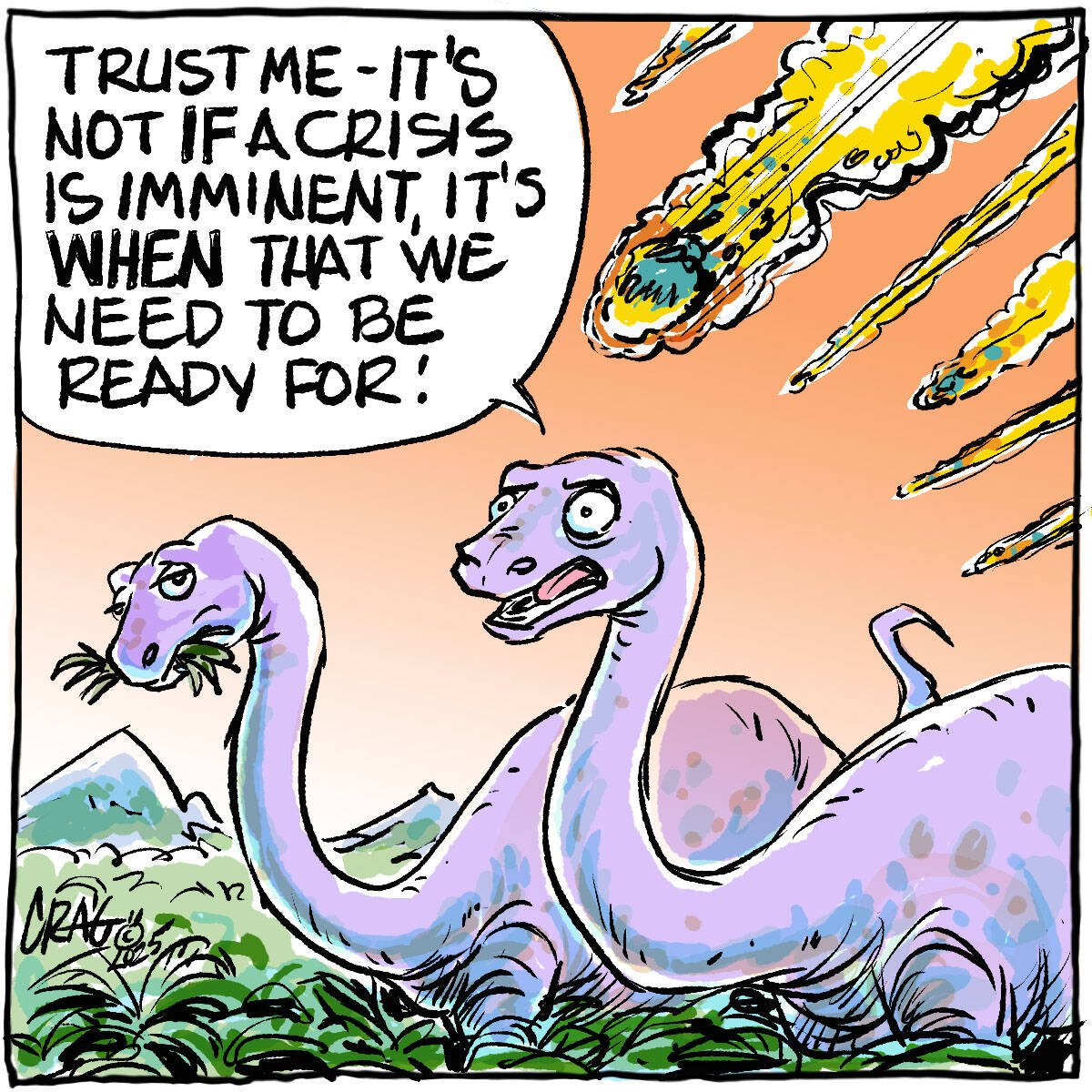

Producers are growing weary over the steady stream of buy-it-early advice. All the stories of impending shortages are fuelling skepticism.

This spring, analysts sounded more certain than ever that fertilizer availability would be a big problem. The same logistical problems curtailing grain movement were expected to spill over into fertilizer delivery.

Scribes including this one, dutifully advised producers to have their fertilizer supply lined up well in advance. In the end, the typical spot shortages occurred, but no supply disaster materialized. Maybe it would have been different if seeding had occurred during a shorter time frame, but to producers it looks like yet another false alarm.

Read Also

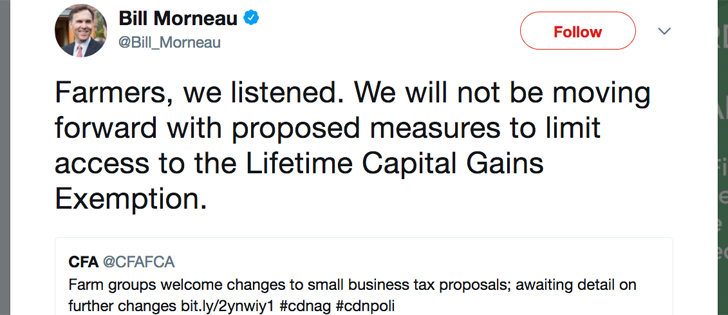

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

The most recent scuttlebutt is to stock up on glyphosate before the price goes up. Some producers will probably heed the advice while others will roll their eyes and proclaim that they’ve seen this movie before.

There have been more shortages of specific products in recent years, whether it’s Reglone desiccant or certain brands of fungicides. You might have to call around to different suppliers or switch to another product.

It’s useful to have products in your own warehouse well in advance of the season of use, but how far should producers go to guarantee supplies? How much needs to be secured how far in advance?

In recent years, there have been alarm bells over the possibility of a diesel fuel shortage. Refinery problems have caused some short-term shortages in Western Canada, but this hasn’t coincided with seeding or harvest.

Still, the fear of a diesel shortage has convinced some producers to in-crease their on-farm bulk storage capacity. Theoretically, this may also provide an opportunity to make diesel purchases when prices are more favourable.

This is certainly the situation with fertilizer. Most of the time, nitrogen and phosphate are less expensive in the fall than the following spring. This past year, the difference was dramatic. The price saving went a long way to paying for storage capacity.

This is not without risk. Does anyone insure their stored fertilizer? Bins can leak or fall over. Product can be stolen. And there are occasional years when prices don’t follow the expected trend.

Producers will often pre-purchase most of their fertilizer, while leaving a portion for purchase around seeding time so they can more closely match their needs. It’s certainly a benefit to the supply chain to have a lot of the fertilizer in place before the season of use.

Harvest is just starting, but soon you can expect to start seeing advertisements to buy canola seed for next year. The newest and best varieties might be in short supply.

With the corn price graph resembling a downhill ski slope, it’s reasonable to expect the price of nitrogen to continue dropping, but at some point decisions will need to be made about next year’s supply.

For a world economy that prides itself on just in time logistics to avoid storage costs, it seems that farmers have become warehousing titans. Not only do they need storage for 1.5 times a normal crop, but they also need to store a large proportion of their inputs long before they’re needed.

Warehousing capability can help farmers lower purchase prices, just like grain storage can help marketing plans. But it takes deep pockets and many farmers are now wary when another supply problem is rumoured.

How do we sort out what’s real and what’s just marketing?