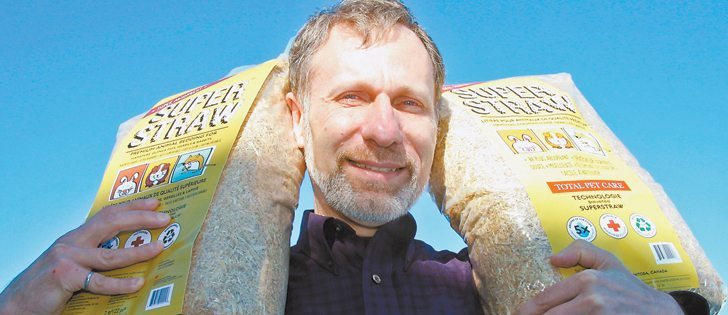

Absorbency a selling point | Unwanted biomass fuel cubes find new market in livestock barns

Eugene Gala and Stephane Gauthier were caught in a classic business conundrum in the late 2000s: they had a better mousetrap but buyers were few or nonexistent.

Gala and Gauthier had developed a dense cube of straw and wood residue at their processing plant in La Broquerie, Man.

The product was designed as an environmentally friendly source of heating fuel that would steal market share from coal.

The business partners needed to charge $80 per tonne for the biomass fuel to make a profit. Coal was selling for $45 per tonne at the time in Manitoba.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

“Once we figured out how to make the product, what we realized is that nobody wants to pay the price for that product,” said Gala, a University of Manitoba mechanical engineering graduate.

“Impossible. Nobody would pay almost double, no matter how green they are.”

The entrepreneurs soon had an unwanted pile of biomass fuel cubes. Desperate to find an alternate market for the technology, Gala and Gauthier noticed the pile was getting larger for some reason.

The manufacturing process had altered the straw and made it highly absorbent. After a period of experimentation, Gauthier and Gala developed a unique animal-bedding product that they now market as SuperStraw.

Gauthier and Gala’s company, Biovalco, has been selling SuperStraw to horse owners, dairy and chicken farms in Manitoba since November through a partnership with La Co-op fédérée in Quebec.

They also produce smaller bags of SuperStraw for the pet market, primarily gerbils, rabbits and hamsters.

“We take the raw straw and refine it…. What comes out is a different product. It’s almost like taking wood and making paper,” said Gauthier.

“It feels like silk, not straw.”

The business partners received a North American patent for the SuperStraw manufacturing process in 2012.

U of M researchers have confirmed that SuperStraw, which is made from oat, barley or wheat straw, truly has super absorbency. Testing has found that it absorbs five times its weight in water. Ordinary straw absorbs 1.3 times its weight.

Gala said the manufacturing process kills most of the hazardous bacteria in the raw straw, and the final product contains almost no dust.

“There’s no binder, nothing. It’s 100 percent natural,” Gala said in the company’s office at the U of M’s SmartPark, a research and technology hub.

“Our goal by the end of this year is manufacturing about 5,000 tonnes…. I believe the demand in Manitoba, alone, should be 20,000 to 25,000 tonnes.”

They are currently focused on selling SuperStraw to horse owners and dairy farms in Manitoba, but their partnership with La Co-op fédérée is expected to open up a much larger equine and dairy market in Ontario and Quebec.

“That would be our goal at some point,” Gala said, noting it’s too expensive to transport processed straw from eastern Manitoba to southern Ontario.

“Probably in the next couple years we will have a facility (processing plant) in Eastern Canada.”

Biovalco, previously called Prairie Bio-Energy, designs and sells biomass-heating systems, including the Blue Flame Stoker, a combustion system that burns wood chips, wood pellets, oat pellets, flax shives and other agricultural residue to generate heat or steam.

Gala has installed the biomass heating system for more than 120 clients in North America, including Hutterite colonies, schools and greenhouses.