It’s the field operation that covers the greatest number of acres in the shortest period of time. Trouble is, a multitude of factors can keep the sprayer from doing its job on weeds.

Wind is arguably the biggest enemy. For spring burn-off operations, when no susceptible crops have emerged in the vicinity, many growers will push the envelope. Weed control is usually good, but you feel rather silly spraying in a gale. You’d rather go unseen.

When crops have emerged, wind becomes a much bigger concern. On the field edges, you can slow down, cut the spray pressure, use wind resistant nozzles, and keep the booms low, but you still worry where the wind is taking the fine droplets.

Read Also

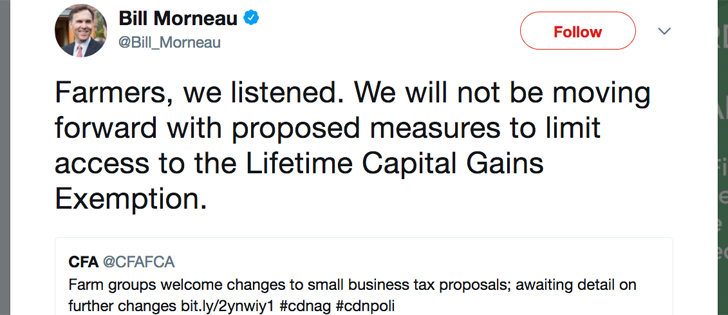

Trump’s trade policies take their toll on Canadian producers

U.S. trade policy as dictated by president Donald Trump is hurting Canadian farmers in a multitude of ways.

Shields and cones cut down on drift, but there’s a trade-off. Shields get coated with chemical and should be washed when going from one product to the next. Both shields and cones make it more difficult to see if every nozzle is performing properly.

Ironically, dead calm can also cause crop damage. When there’s no wind, inversions can occur causing a big cloud of droplets to migrate to adjoining fields.

Some growers spray at night when winds are usually lighter, but studies show that efficacy often drops after the sun goes down.

When you finally get light winds, you have to worry about when the next rain is coming.

How many times have you checked the herbicide application bibles looking for how quickly a product is rain fast?

And, of course, the crop and the weeds need to be in the right stage or you don’t want to be spraying anyhow. I have stinkweed in a brown mustard crop. The only product registered is Muster Toss-N-Go. The mustard is supposed to be at least the four-leaf stage or crop injury could result. The stinkweed needs to be in the one to four leaf stage.

This seems to assume that all the mustard germinated at the same time and all the stinkweed germinated shortly thereafter. It’s not always that clear cut. You can do a lot of field scouting trying to get the timing right.

Many products have wide application windows, but you still worry about going too early and missing late-germinating weeds or going too late and suffering a yield depression due to weed competition.

And do you go for products that do the best job of killing your weeds, even if they have re-cropping restrictions? I considered Ares on Clearfield canola, but you can’t seed durum the following year.

Prestige is a cocktail of fluroxypyr, clopyralid and MCPA Ester and provides good control over many troublesome weeds in cereals including canaryseed, but you can’t seed lentils the next year.

Going through all the weed control options and tracking down your choice of products can also get in the way of actual application.

Meanwhile, you try to minimize the number of times you go from one product to something entirely different.

Sprayer clean-outs aren’t fun and you always have that niggling fear of residue that could hurt the next crop you spray. Sometimes an application is postponed just to avoid another clean-out.

So if the wind isn’t too high or in the wrong direction, and if it isn’t dead calm, and it isn’t after dark, and there’s no rain or cold temperatures in the forecast, and you have your product picked out, and your sprayer is cleaned and loaded, you can spray a lot of acres per hour.