Determining when an investment in new or new-to-you equipment is warranted often seems more of an art than a science.

Machinery purchase decisions bedevil many producers, and I’m one of them.

You can point to reliable pieces of equipment in your fleet that have performed above and beyond their call of duty. You can point to other purchases that were big money and time wasters.

The old Versatile seeding tractor we use is 35 years old and creeping up on 10,000 hours. Purchased seven or eight years ago, it has been a great investment. It certainly isn’t fancy, but it has done the job with fairly minimal repairs and only a day or two of down time.

Read Also

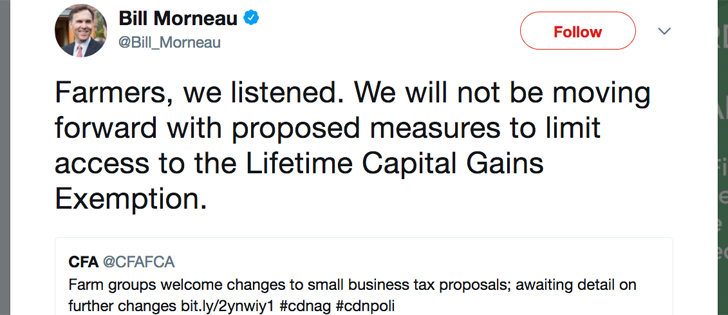

Budget seen as fairly solid, but worrying cracks appear

The reaction from the agriculture industry to prime minister Mark Carney’s first budget handed down November 4th has been largely positive.

When is it time to trade up?

Extra horsepower and more hydraulic capacity would be good, and the old tractor is eventually going to need some major work and new tires. However, you could buy something 15 years newer with half as many hours and still end up with repair bills and down time.

Older combines are much worse than old tractors for repairs. There’s just so much to wear out. If you buy a $40,000 combine and put $40,000 worth of repairs into it, what is the combine worth at auction? Certainly not $80,000.

We have two 20-year-old combines that we try to keep running. When one is laid up for a day or two, the other one is hopefully still running. This sort of equipment redundancy is probably not recommended in any farm management textbooks, but it provides piece of mind.

Buying a bigger seeding tractor and keeping the old one as a spare doesn’t seem like a viable plan. At some point, you’re likely to upgrade seeding equipment and then the old tractor won’t be of any use. However, maybe it would be good to keep the old tractor around for the first year.

Seeders are another vortex of considerations. The standard shank drills have depreciated in value with the major move to on-row depth control and packing systems. Do the new seeders result in significantly higher yields? How many acres does it take to pay the additional cost? Will these seeders still be in the field in 20 years like many of their predecessors?

New equipment is far from trouble free. A new tractor might have niggling issues with diesel emission equipment. A new drill might have electronic problems. Of course, new equipment is under warranty, but the downtime can still be frustrating.

Many wrestle with whether to buy belt conveyors rather than grain augers. On the upside, conveyors last much longer and they are much gentler on crops while providing good capacity. Because they clean out completely, you don’t have to worry about contaminating one crop with another.

On the downside, conveyors cost a lot more than an auger, they aren’t suitable for some crops and you need a lot of length to load high bins because they can’t operate at a steep angle.

Your volume of production and mix of crops are important in the conveyor versus auger decision process.

But in the end, it tends to be a judgement call, just like it is for most of the equipment buying decisions that can make or break the farm.