If, as the song goes, there must be 50 ways to leave your lover, there must be at least that many ways to have seeding misses.

See if any of these resonate with your experience:

Fertilizer lumps

All too often there are various rocks and chunks in the fertilizer supply. This isn’t just fertilizer lumping up in storage. These are obstructions that you would need a hammer to pulverize.

We screen all the fertilizer coming from the bin, but smaller chunks still get through, and we end up digging them out of the distribution towers on the drill. It’s a fertilizer quality problem that seems to be getting worse.

Read Also

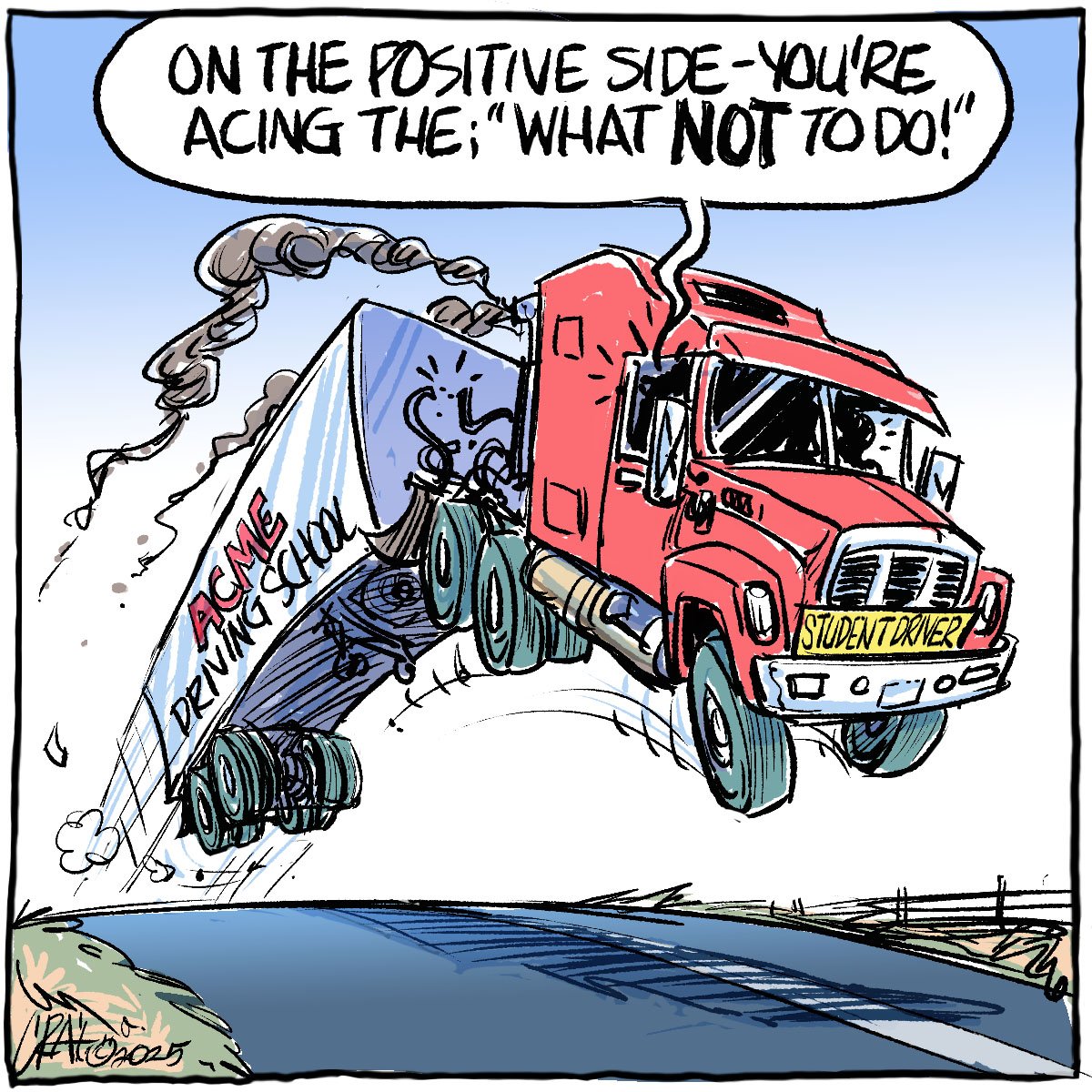

Efforts to improve trucking safety must be applauded

The tragedy of the Humboldt Broncos bus crash prompted calls for renewed efforts to improve safety in the trucking industry, including national mandatory standards.

Birds

The problem is more specifically with bird nests. Any auger that sits for more than a few hours will have the start of a new nest. Forget to run the auger before it’s over the truck and you’ll have stems and straw and feathers in your seed.

A spout on the auger seems to deter nest building. However, you can still have mouse nests if those little beasts decide to crawl in from the bottom and start a family.

Seed bag residue

Sure, the bag opens when you pull the tab, but try to open and dump a whole bunch of bags and not drop a string, a seed tag or strip of paper into seed. You should almost dump seed bags through a screen.

In this case, it might not be a run that gets blocked. Paper strips like to lodge at the seed meter and can affect the flow of product for acres and acres.

Inoculant residue

If you use your seed cart auger to apply a peat inoculant, residue can build up and dislodge as lumps. If you use a bit of water to help inoculant adhere to the seed, you need to be careful not to cause bridging in the tank. This can be a difficult problem to detect because everything is turning and the air is still blowing.

Mud

Almost all openers will plug if conditions are wet. Some are more prone to plugging than others. This is a much bigger problem on clay or gumbo soils.

Plugging issues increase with seed size. A big seed means a high seeding rate and you need more air flow. However, you don’t want to crank up the air velocity so much that the seed is damaged.

Kabuli chickpeas are the worst for us. In addition to being large, they have that little beak on them, hence the chickpea name. They can jam up in the darnedest ways.

Unplugging an individual run is a relatively quick fix. Unplugging an entire tower and the big hose all the way back to the seed cart can cost you a lot of time, not to mention an ugly looking miss in the field if you didn’t catch it right away.

Broken or detached hose

The small drop tubes eventually get brittle and want to break off. They can also pull out of the tower or the ground opener. Big hoses will eventually have holes from the constant flow of product. Sometimes you can see product spewing out as you drive down the field, but sometimes the leak goes for a while before you catch it.

Many producers operate without blockage monitors on their drill. Our blockage monitor prevented an ugly seeding miss and some lack of fertilizer stripping this spring. Blockage monitors are expensive, but they are a good investment.