Last winter caused widespread disruption in freight supply chains across Canada, and railways were certainly not immune.

The service they were able to provide during weeks of exceptionally cold weather fell well short of many customers’ requirements.

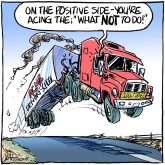

Critics were quick to suggest that railways were poor planners focused on cutting costs at the expense of service and that they simply didn’t care about their customers.

Railways were also accused of under-investing and lacking the capacity to handle large volumes of traffic.

Last March, the federal government introduced its Fair Rail for Grain Farmers Act, and Canadian National Railway and Canadian Pacific Railway must now move a minimum amount of grain per week or face hefty fines.

Read Also

Higher farmland taxes for investors could solve two problems

The highest education and health care land tax would be for landlords, including investment companies, with no family ties to the land.

However, a study that I recently conducted for the railways and presented to audiences across the country shows that the railway in-dustry was at the mercy of a difficult weather pattern that wrought havoc on their basic technologies for weeks on end.

All outdoor industries suffer during the winter, especially those involved in transportation and logistics, but railways are uniquely affected.

The same technologies that make railways highly efficient, low-cost service providers — steel wheels running on steel rails and harmonized air brake systems that allow trains to move seamlessly across the rail network — are also affected by a cold-weather tipping point at about -25 C.

Steel becomes less ductile, making rails more susceptible to breakage and wheels more prone to tread damage.

Air brake systems are also challenged as air leaks at gaskets and elsewhere cause braking systems to lose pressure and force railways to run much shorter trains for safety reasons.

These and other factors can result in a downward spiral of delays. And, of course, winter’s effects on other members of the supply chain can affect rail carriers, reducing their performance even further.

For example, an export terminal may stop inbound rail deliveries because of a winter storm at sea, which backs up trains already en route, causes congestion and reduces the supply of empty equipment for inland shippers.

However, in spite of the many challenges posed by the 2013-14 winter, Canada’s railways weren’t resting on their laurels, as some critics have suggested.

Even in the depths of winter, they moved more traffic than they did during the summer of 2011, which shows that capacity investments in infrastructure, equipment and people have been ongoing and in line with the demands of the economy.

All of this points to the fact that the issue with winter is not capacity. Instead, it is resiliency, which is the ability to withstand the shocks brought on by a harsh winter, given the technologies that make railways railways.

Canada’s railways make significant investments to ensure that they are as resilient as possible: more than a billion dollars each a year to renew infrastructure, support service improvements and develop technologies to offset some of winter’s negative effects.

However, key opportunities for reducing winter backlogs also lie within the supply chain itself, such as joint planning, improved forecasting, shared-access systems for real-time information, shared performance metrics to drive accountability and action, and other logistics initiatives such as increased storage capacity, product movement in advance of severe weather and the development of multiple export corridors.

The notions that railways are under-investing, not planning properly for winter and focused only on cost savings are ultimately not based on fact.

Furthermore, it isn’t reasonable to judge service or contemplate policy and regulatory action based on railway performance during the worst eight to 10 weeks of winter weather last year.

As the mercury dips in early 2015, Canada’s railways can only hope that all parties focus on the facts rather than rhetoric and on working together to improve service and efficiency across the supply chain.

Paul Miller is adjunct professor at the University of Alberta’s civil and environmental engineering department and railroader in residence at the Canadian Rail Research Laboratory.