REGINA – At the Western Canada Farm Progress Show, McLeod Harvest Inc.

has moved onto the blacktop where it competes for attention with the

big players.

This transition, from a curiosity in the new invention showcase a few

years ago to a display with all the usual trappings of tent, videos and

glossy brochures, is the outward sign of a maturing company.

The addition of a new European investor has helped the company slate

production of 25 to 30 units to be in farmers’ hands by harvest 2003,

Read Also

Industry wants ag to become national priority

Agricultural associations from across the country have agreed they want the prime minister to treat agriculture and agri-food as a strategically important sector.

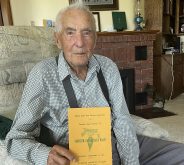

said president Bob McLeod.

“We are using this show (to mark) the change in ourselves from a

research and development company into a commercial enterprise,” McLeod

said.

“We are hiring salespeople. We didn’t have salespeople before because

we weren’t selling.”

The McLeod Harvester system is a new take on harvesting. A pull-type

harvester collects the grain, chaff and weed seed from the field. A

grain truck delivers it to an electric or diesel-powered cleaning mill

that separates the grain and processes the chaff and weed seed into a

quality livestock feed that McLeod calls “graff.”

This harvest, four units will take in crops on two farms in Alberta and

two in Manitoba.

McLeod hopes that through farm equipment shows during the summer and

on-farm demonstrations this fall, he’ll gather orders for at least two

dozen units for 2003 delivery.

The mill-cleaner will be made by Loewen Manufacturing at Altona, Man.,

and the main body and assembly of the harvester will be done by

Northland Superior Supply Ltd. in Winnipeg.

To help inspire confidence, McLeod Harvest has an introductory offer of

a money-back guarantee.

If after the first harvest the buyer is dissatisfied, the company will

return $165,000 of the full $185,000 price tag. It will pay $145,000

after the second season.

“But we are convinced that once they start farming with it, they will

stay with it.”

New investment helped make the buyback offer possible.

In March, Emergo, a group of private companies with Dutch origins based

in Geneva, Switzerland, invested $1.5 million in McLeod Harvest Inc.,

representing a 26 percent equity interest.

“They have operations around the globe and they could be very

instrumental in helping us as we are ready to embark on international

markets,” said Gord O’Keefe, business development and finance officer

with McLeod Harvest.

“They recognize like we do that’s premature, but it is not that far

down the road either.”

The company is committed to a slow but steady evolution. It is a

strategy backed by the company’s other investors, which include

Winnipeg area businesspeople and Manitoba Hydro.

“We have to be very careful. Our worst fear is that some guy will buy

it and say ‘ah, it’s a piece of junk.’ It would kill us,” said McLeod.

“Taking on the combine is no small task. The combine was invented 150

years ago and we are the first serious ones to take change in

technology to the combine. It is a serious rethinking that has to take

place.”

For example, some farmers think the system would be slower than a

conventional combine because so much more material would have to be

unloaded from the harvester and trucked away.

McLeod disputes this. The truck driver would certainly be much busier

than one serving a regular combine, but there should be no delay of the

harvest.

Working within the recommended 6.5 kilometre radius of the grain

mill-cleaner, a 20-foot tandem truck should be able to keep up with the

harvester’s 750 bushel tank, he said.

For mixed farmers, the system’s ability to produce feed could eliminate

the need to produce or buy hay, saving time or money.

The first owners of the system, Don and Ken Armitage of Miniota, Man.,

used it for last year’s harvest. O’Keefe said the graff kept their herd

of 135 cows fed from November to April, replacing 650-700 round bales.

If valued at $40 a bale, that’s worth about $28,000.

Other benefits flow from the fact the harvester takes all the weed

seeds and drops little grain. This should lead to cleaner fields, fewer

volunteers and reduced herbicide costs.

McLeod is convinced that once farmers see the system in operation and

its financial benefits, it will sell itself.

“Twenty-five machines out there, I tell you, will get 100 machines out

there and 100 machines out there will get us 300 machines out there,

because the economics are so powerful.”