Trait development company uses gene editing in its quest to reduce or eliminate the need for fungicides to control disease

One challenge in producing disease-resistant canola is to make that resistance last, said Peter Beetham.

“One of the problems that plant breeders have always had when it comes to resistance is understanding how you bring about durable disease resistance,” he said. “Durable is a really key term because durability comes from a plant having multiple defences against a pathogen.”

Beetham is president and chief operating officer of Cibus Inc., a San Diego company that uses their proprietary rapid trait development system (RTDS) — a suite of gene-editing technologies — to bring traits such as disease resistance into crops.

Read Also

Manitoba beekeepers battle for survival

Honeybee colony losses have hit 43 per cent, making 2025 the latest in a string of poor bee survival years for Manitoba’s honey producers

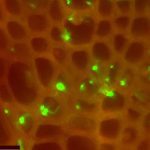

The company recently reached a milestone in stacking two different modes of action against sclerotinia into canola and proving their effectiveness in greenhouse tests.

Greg Gocal, chief scientific officer at Cibus, said in a news release that this complex approach to sclerotinia resistance can be achieved more quickly with the RTDS system than conventional breeding.

The goal is to produce a genetic package of durable resistance to sclerotinia for canola. Once this is done, Cibus licenses the traits to seed companies to incorporate into their own varieties. Its systems are set up to fit into other companies’ development infrastructures.

Beetham said they have developed relationships with 10 entities in North America and Europe. Canada may have a slight edge in getting these technologies into the field because of the importance of canola here and because Health Canada has determined that gene-edited crops will be treated no differently than those developed with traditional breeding methods.

This is an advantage over more onerous and expensive regulations governing transgenic crops that use genes from other organisms. Gene-edited crops use only the crops’ existing genetic material.

“That is the global trend, that gene editing will be regulated as (conventional) plant breeding,” Beetham said.

He said canola has two complete sets of chromosomes to work with from its ancestors, Brassica rapa and Brassica oleracea.

“The genetics in canola, the diversity that is there is remarkable,” he said. “It’s a combination of rapa and oleracea, two genomes that were put together. We can now look at discovering areas within the genome that you could target and edit and bring back the (sclerotinia) tolerance.”

Producing durable resistance may reduce or even eliminate the need for fungicides, which would save farmers money on chemistry and fuel. It would also cut carbon emissions from crop protection products and fuel burned.

“We would love to see farmers be more profitable per acre,” Beetham said. “We would love to see less impact on carbon when it comes to putting big sprayer rigs across the field and then also using chemistry that is expensive and uses fossil fuels to manufacture.”

A feature of disease resistance is that plants often fight off pathogens using similar strategies. That means that when researchers find genes that confer resistance to sclerotinia or other diseases, they can go looking for similar genes in other crops, something called comparative genomics.

For example, sclerotinia afflicts canola and other crops such as soybeans, peas and lentils. While soybean is one of the crops Cibus focuses on, Beetham said Cibus isn’t working with pulses, although they are open to opportunities.

“We’re not actively working in pulses, unfortunately,” he said. “We would love to, if partners were interested in talking to us about pulses.”

Cibus announced earlier in June a merger with another biotech company named Calyxt. The combined company will use the Cibus name.

Beecham said the deal will add Calyxt’s offices, laboratories and breeding facilities and scientific personnel at Roseville, Minnesota, to pursue crop trait development efforts.

“Calyxt and Cibus were two of the pioneers and we’ve put them together,” he said. “Really now with gene editing in agriculture we have by far the leading edge on both the technology knowledge as well as the application to put it into major crops.”

For canola, the merger will put research facilities into U.S. production regions in Minnesota and the Dakotas, as well as the Canadian Prairies.

Cibus currently has offices in Winnipeg and Minneapolis and conducts Canadian field trials.