New Holland reveals CR11

New Holland’s CR11 combine has a 775 horsepower C16 engine mounted lengthwise so that it spins in the same direction as the rotors.

Geert Nerinckx of New Holland said the combine is bigger than what’s currently on the market.

“Our goal with this new combine was to bring down the total cost of harvesting for the customer, especially with regard to grain loss,” he said.

Other stories in the 2023 Canola Yearbook:

- Decent yields in dry times

- Canola views – photo essay

- Canola growing season in review

- Spraying in dry times can be tricky

- Flying the fields

- Hormone imbalance suspected for malformed racemes

- Incorporating resistant traits weighs on yields

- Pest roundup: Canola pests kept in check by dry conditions

- Disease roundup: Verticillium has breakout year

- Canola news briefs

- Canola growers scramble to address federal policy issues

- What happens when the big crop comes?

- Bids tumble but canola demand is firm

The CR11’s driveline has been simplified compared to previous models with 25 percent fewer components.

Drivelines have been removed from this side of the chassis, which enabled engineers to increase the chassis and threshing channel by 13 percent.

The machine’s 24 inch rotors bring power to the front of the machine.

The CR11 has a 20,000-litre (568 bushel) grain tank and can unload 210-litres (5.9 bushel)s per second.

Nerinckx said the availability of the CR11 will be limited in 2024.

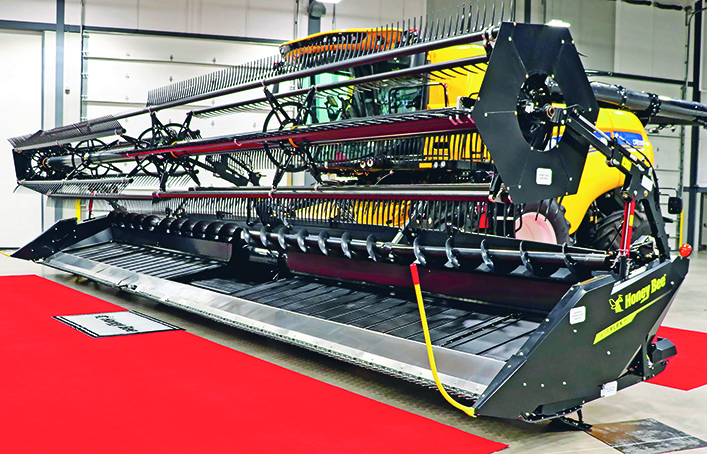

Float like a butterfly cut like a Honey Bee

Honey Bee launched its Airflex NXT header, including a 60 foot model.

“This will be the largest flex table on the market today. It’s not for everybody,” said Perry Gryde, North American sales manager for Honey Bee.

“That will match up pretty much any combine on the marketplace. So, whether it’s the John Deere X9, the Claas 8900 or the 10.9 New Holland. We have no preference over the model and we will match up to it.”

The AirFlex NXT uses a reversible, mechanical knife drive at the centre of the header that allows for a slender crop divider end shield. The vertical shears help get through bushy crops like peas and canola.

The suspended cutterbar system on Honey Bee’s Airflex NXT headers use skid shoes adjustable from the cab.

Honey Bee’s Air Flex lineup uses gauge wheels on each side of the feeder house that hold most of the header’s weight in flex mode, and all of its weight in rigid mode.

Strip till works for irrigated seed canola

During a crop tour of a seed canola field test hosted by Farming Smarter, researcher Lewis Baarda presented the results of a study that compares direct seeding, full till and strip till.

“Strip till is performing as good as anything else,” said Baarda about the yield trials.

“We didn’t see a lot of difference between treatments.”

When it comes to erosion, Baarda said strip till provides much better ground cover compared to the full-till treatments.

However, strip till comes with challenges, according to John Kolk, who farms near Lethbridge.

It’s costly to get started because it requires specialized equipment and precision accuracy to till the narrow strips where seed will be planted.

“The trick to erosion is either you got big enough lumps or trash on top or something to break the wind. You want to slow the wind speed down at the surface,” said Kolk.

“When you strip till, you are leaving 12 to 16 inches of undisturbed stubble and the wind doesn’t dip into that, it goes over top and then it’s quite a significant improvement.”

Outside of irrigated crops, Kolk said he doesn’t think strip till has much of an advantage on dryland canola, except for high moisture areas.

SeedMaster joins double axle air-cart club

SeedMaster introduced the E Series air cart, its first wagon-style offering.

“It’s still in the pre-production prototype stage, but we’re here to show it off to let all of our customers know that we’re working on something new and innovative in our seeding lineup,” Tim Criddle, global sales director of SeedMaster, said during the first day of the Ag In Motion outdoor farm show held this past summer near Saskatoon.

The addition of a steering front axle will help the company distribute the weight across more tires and increase its capacity to compete with the larger air carts on the market.

On display at Ag In Motion was the E820, which will initially come with three tanks: front and back 325-bushel tanks and a 170-bushel centre tank.

In addition to that, “we have a fully integrated UltraPro3 (UP3) canola tank that gets installed on the toolbar,” Criddle said.

“When I see fully integrated, I mean from an operational control point of view. They may be separate in that the 80-bu. canola tank is not on the cart, but it is integrated to operate.”

For growers who want to stick to a more conventional configuration with a canola tank on the cart itself and not on the toolbar, a 60-bu., rear-mounted canola tank will be offered on the air cart.

Group 14-resistant kochia found in central Saskatchewan

A kochia population collected from central Saskatchewan in 2021 is resistant to Group 14 foliar and soil residual active ingredients.

Charles Geddes, a research scientist in weed ecology at Agriculture Canada’s research centre in Lethbridge, said growers dealing with kochia should keep a lookout for this type of resistance.

“I think it is a significant concern. The biggest concern that I can see is for the pre-plant burn-down window,” Geddes said.

He said farmers in conservation and no-till systems traditionally used glyphosate for their pre-plant burn-downs.

Once glyphosate-resistant kochia started showing up, many growers mixed in a Group 14 product with glyphosate for burn-downs.

However, in areas where the kochia developed glyphosate resistance, this meant there was only a single effective mode of action on kochia, which caused selection pressure for Group 14 resistance.

“Now we’re seeing at least the first cases of Group 14 resistance in Western Canada. With kochia, herbicide-resistance traits can spread quite rapidly. So, it’ll be important for scouting efforts to keep an eye on the potential for this showing up in fields moving forward,” Geddes said.

Volunteer canola under the microscope

Volunteer canola is the second most common weed on the Prairies, according to the most recent Agriculture Canada survey of weed abundance that took place in 2019 and 2021.

This is why Caroline Brown, PhD candidate at the University of Manitoba, is identifying genes that control secondary dormancy in canola.

She said primary dormancy in canola is not common, but it occurs on the mother plant to prevent pre-harvest sprouting.

“Secondary dormancy occurs once the seed is matured and is faced with adverse conditions — like low light, moisture, and temperature. The seed knows it’s not a good time to germinate because it’s not going to survive,” Brown said.

“So, it’s able to be induced into this secondary dormancy, which it can persist for a long time before conditions become more favourable.”

Brown is working on phenotyping a diversity collection of canola varieties and collecting the data on different dormancy levels, and then associating those dormancy levels with the canola genomes that have been sequenced.

Why do some canola varieties have more tolerance for cold soils?

Mark Smith and his colleagues at the Ag Canada research station in Saskatoon are applying a targeted approach to identify new traits to confer improved low temperature tolerance in seedling canola.

“If seed germination, and particularly seedling establishment could be improved in cool spring conditions, it might be possible to beat the heat and increase yield. Faster growing seedlings could also suffer less flea beetle damage too,” said

Smith and his colleagues have conducted tests in a greenhouse, where canola seeds are planted in pleasant soil temperatures like 18 C and others are seeded where it’s closer to 6 C.

“Right now, we’re not looking at too many hybrids. We’re looking at some of the open-pollinated varieties,” he said. “(But) there are clear differences in the way they grow…. If we can find out what factors give it that edge in germinating, and (if) we know the genetics behind it, that might be something that could be transferable to a breeding program.”