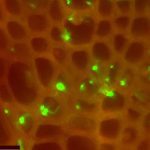

Sometimes, as in the case of grasshoppers, it really isn’t over till it’s over.

The effect of this year’s grasshopper infestation didn’t end at harvest time, but has continued on into the harvested grain, where their body parts can cause downgrading.

“The Canadian Grain Commission has a 0.02 percent tolerance for grasshopper parts in all pulses, so producers should consider scalping their crop – passing it through a screen – before bringing it in,” said Ray McVicar, a special crops specialist with Saskatchewan Agriculture.

“Processors do clean these crops but, if a load is particularly dirty or has a strong odour, they may be reluctant to take it because of the extra cleaning time required.”

Read Also

Alberta crop diversification centres receive funding

$5.2 million of provincial funding pumped into crop diversity research centres

Unfortunately, producers can do nothing about the staining that occurs when crops are harvested with high grasshopper populations.

Not only does the stain cause downgrading, but dust sticks to the kernels increasing dirt, which results in further downgrading.

Grasshoppers, which have a high moisture content, also increase the risk of spoilage, although the risk is greatly reduced if the body parts are immediately removed.

The risk of pulse crops spoiling in the bin is particularly high this year because of the hot temperatures at which the crops were taken off. Because of their large seed, chickpeas and peas are particularly susceptible to mould.

McVicar said these large-seeded crops need time for the moisture to be equalized throughout the inside of the seed, which is known as going through a sweat. If crops are harvested at high temperatures, there is a strong possibility the seeds will sweat in the bin, which leads to mould. Aeration is the key to avoiding this, since it cools and dries the seed.

“Stored grain should be checked a number of times after harvest. Moisture conversion charts for use with moisture meters are available for pulse crops, including chickpeas.”

For prolonged safe storage, pulse crops should be cooled to less than 15 C and dried to less than 14 percent moisture. Seed that is cooled to 10 C will store well for long periods.

A bin equipped with an aeration fan can provide cooling and drying. However, while cooling may be completed in one day, drying can take three to four weeks. To do this, the aeration fan must have adequate power to provide air flow through the grain. The recommended requirement for aeration drying of a pulse crop is about one to two cubic feet of air per minute per bushel, which is about 2,000 to 4,000 cubic feet per minute for a 2,000 bu. bin.

A crop’s cleanliness is another factor during aeration because foreign material can greatly reduce airflow and channel air movement around wet spots. This is one more reason to screen out grasshoppers.

Round baler

John Deere’s new 582 Silage Special Round Baler is designed for those who need to precut a silage bale. It produces a bale four feet wide and up to five feet tall.

The variable chamber allows the operator to adjust bale size according to needs.

The powerline that drives the baler from the tractor incorporates an 80-degree constant-velocity u-joint. It also has a cam-type cut-out clutch that provides protection against crop overloads and automatically reengages when tractor rpms are reduced.

The high capacity 78-inch-wide pickup features four toothbars and a low-profile, 10-inch-diameter pick-up drum.

A standard hydraulic pickup allows the operator to raise and lower the unit from the tractor.

In the precutter system, the rotor cutting mechanism rotates across a fixed set of 14 spring loaded knives. The double pointed fingers pull the crop through the knives for excellent cutting. Precutting the crop increases bale density, improves feeding and creates a more palatable crop.

The baler uses the BaleTrak Plus monitor-controller. The 24-bar display on the monitor shows bale shape within the chamber and allows the operator to make tight, square-shouldered bales.

Two wrap systems are standard: twine and CoverEdge net wrap, which wraps two to three inches over the edge of the bale.

Water pipes

Reinke has a range of pipe for mechanized irrigation systems.

Pipe selection depends on water composition, including levels of chloride, sulfate and pH, and is best done with the assistance of an expert.

Reinke offers four pipe options: galvanized steel, stainless steel, aluminum and chromium nickel copper alloy.

For more information, contact Reinke at 866-365-7381 or visit www.reinke.com.

Fencing switch

Ferris Fencing has a new switch for electric fencing that enables operators to work on part of a fence but keep the rest of it electrified.

The switch can direct current to either of two fences or both.

For more information, contact Ferris Fencing, 430 Grovehill Road, Qualicum Beach, B.C.,V9K 2A3, phone 800-665-3307 or visit www.ferrisfencing.com.

Outdoor biffy

Koenders’ new Poly Potty comes assembled with a urinal, toilet seat and toilet paper holder.

The unit weighs 200 pounds and is movable by a forklift or crane with the solid plastic base that includes moulded-in T-nuts and cable kit option. It is 92 inches high by 41.5 inches wide and 43 inches deep.

The 40 gallon capacity vented holding tank is tapered to the middle for efficient pump out.

A three inch spin fitting can be installed at the back of the tank upon request to allow the tank to be drained in any situation.

The tank is made from medium density polyethylene.

An optional handle kit is available.

For more information, contact Koenders at Box 171, Englefeld, Sask., S0K 1N0, phone 877-581-8877 or visit www.koendersmfg.com.