On the Farm: Anna Hunter and Luke Palka moved to the country so they didn’t have to raise their children in the city

Anna Hunter admits that she and husband Luke Palka were novices in agriculture when they bought their 140-acre property in Ste. Genevieve, Man., five years ago.

Located near the edge of Manitoba’s boreal plains, the land is a diverse mix of poplar, spruce and pine trees, open pastureland and wetland containing a creek. A variety of animals and birds share the family’s land.

“We chose this property because of that. We are not trying to force ourselves in the land base but are working within it,” Hunter said. “We knew we wanted to live in a rural area, and grow our own vegetables and raise our own meat.”

Read Also

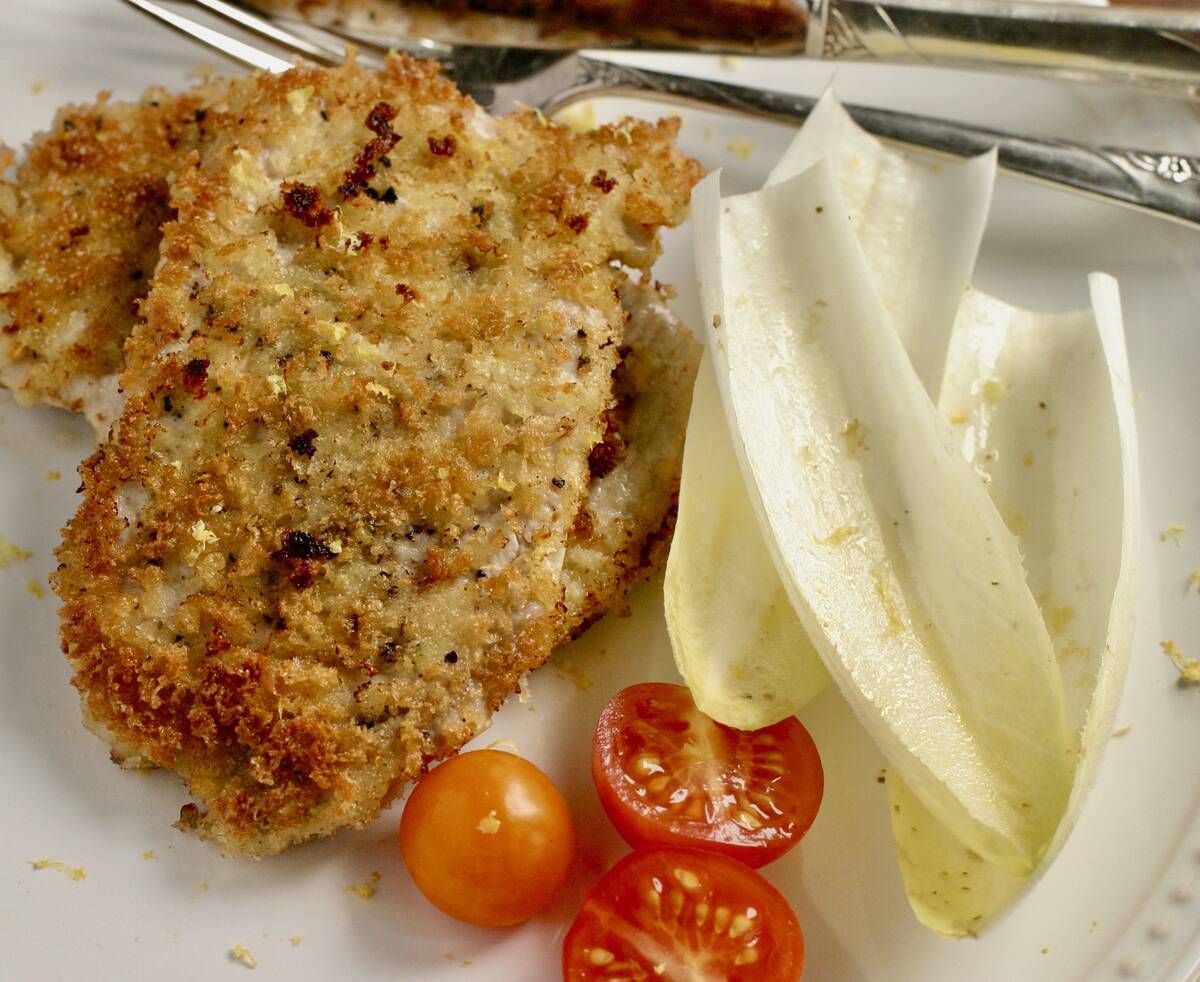

Nutritious pork packed with vitamins, essential minerals

Recipes for pork

She said she grew up in Calgary and Palka is from Winnipeg. They met in Halifax, then reconnected and married in Vancouver where their sons Bohdan, 10, and Josh, 8, were born. Hunter and a partner operated a business called Baad Anna’s Yarn Store in Vancouver for six years, but the couple didn’t want to raise their children in a city so they started looking for a rural property not too far from Winnipeg. Palka runs a fine art handling business and also does custom carpentry.

The name for their farm arose from a long-standing joke that Hunter and Palka like to do things the hard way or long way.

Hunter, whose job title on her business card is “shepherdess,” knew that she wanted to establish a flock of sheep and found that the Shetland breed is best suited to grazing on their land.

“They are a heritage breed and hardy foragers.”

She noted that they also produce fleece in 11 distinct natural shades. “It’s really stunning.”

They have added a few Merino crossbred sheep to their flock that now stands at 45, as well as a llama and llama-alpaca cross. The couple also raises laying hens and meat chickens and have had heritage breed pigs in previous years. They are in the process of rehabilitating 10 acres of pasture land that formerly held cattle and horses. They use electric mobile fencing to move their flock onto a new grazing area every two or three days depending on the weather conditions.

Hunter said they will sell some of the rams and cull the flock down to between 30 and 35 animals later this year, selling some of the meat and keeping some for their own use.

She said she tried to follow a 100-mile guideline for sourcing yarn for her store in Vancouver, but soon discovered that there were no large-scale wool mills within that geographic area, with the closest being in Alberta. Because of this, there was a 18 to 24-month waiting period to have fleece processed and the large mills only accepted orders of more than 40 pounds of fleece.

“I realized that there is an opportunity here, and I took the idea and ran with it.”

She and Palka visited Belfast Mini Mills on Prince Edward Island that manufacturers small-scale equipment to process fleece and fibre. Hunter had thought she would have to construct a new building to house the equipment but she was able to fit it into their garage. She has processed her own flock’s fleece and fleece supplied by her customers for the past two years, including llama, alpaca and bison.

“We can process any kind of animal-based fibre.”

The minimum weight of fleece is three lb. so it is attractive for people with small flocks. Hunter offers finished products of roving and batts, two- or three-ply chunky weight and fingering, and single-ply Lopi style yarn.

She usually buys about 1,000 lb. of fleece from other sheep owners to process into yarn that she sells under the Long Way Homestead label.

Another one of Hunter’s dreams has been realized — that of growing plants that she can use to create natural dyes for her yarn.

“Natural dying was a priority. I had to look at what types of dye plants we could grow.”

She has three small gardens this year in which madder, cosmos, marigolds and coreopsis are among the plants that she will dry and use to produce a variety of naturally coloured dyes. She also harvests local wildflowers like goldenrod, yarrow and tansy for dyes.

Hunter is one of 25 members of the Pembina Fibreshed in Manitoba who are experimenting with cultivating Japanese indigo to produce the relatively rare dark blue shade named indigo.

She said her former business partner in Vancouver taught her how to process blossoms and roots of plants to produce natural dyes. She is passing on her knowledge through small group tours and workshops held on her farm.

“I hope to expand my dye garden operation at some point.”

These small-scale events, which are usually held outdoors, are a response to restrictions arising from the COVID-19 pandemic, Hunter said, In previous years, she and Palka opened their farm for an annual shearing festival in April, and had more than 200 people attend.

Hunter said being able to offer small group tours has allowed her to share her knowledge of wool production and natural dying techniques with others interested in spinning, weaving, knitting, crocheting and felting. Participants are able to book a tour through the Long Way Homestead’s website.

“It’s definitely helped with the income loss from the cancellation of large events.”

Her plans to attend major fibre festivals in Montreal, Vancouver and Winnipeg have been postponed because of COVID-19, but she has turned a shipping container into a small shop on her farm and is taking part in some farmers markets this summer. She also sells her yarn online and at Wolseley Wool, a Winnipeg yarn store.

As people are spending more time at or close to home because of the pandemic, they are increasingly trying their hands at crafts such as fibre arts and the demand for fleece processing hasn’t decreased over the past five months.

“It’s hard to know what opportunities the future will hold,” Hunter said.