In the grand scheme of things, this may seem rather unimportant, but after weeks of herbicide application while trying to dodge gale force winds, here are some thoughts on the packaging of crop protection products. See if you agree and if you do perhaps manufacturers will consider changes.

Handling products in bulk is great, but sometimes the acreage you have to spray doesn’t justify a large quantity or you’re tank mixing and not set up to handle two products in bulk. Also, there are products only available in jugs.

Read Also

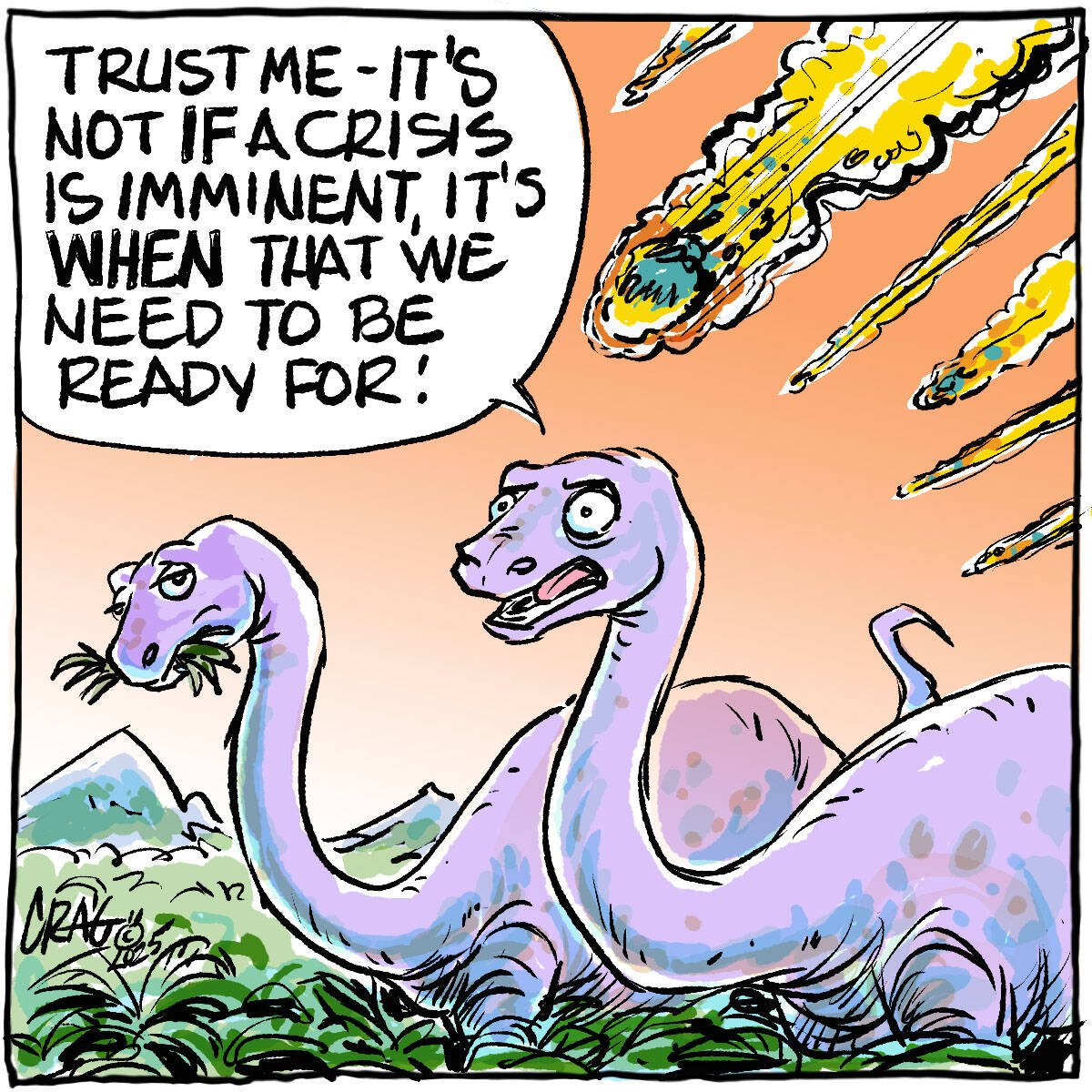

Proactive approach best bet with looming catastrophes

The Pan-Canadian Action Plan on African swine fever has been developed to avoid the worst case scenario — a total loss ofmarket access.

Thank goodness for the chemical container recycling program because a farm can go through a mountain of jugs during the growing season.

Let’s start with the boxes holding the jugs. Each box has a hand-hold cut-out on each end. Some of these are so wimpy and so close to the lid that they’re prone to ripping. I don’t want to disparage specific manufacturers, but Bison herbicide is bad for this.

You probably aren’t supposed to carry a box with each hand using just one handhold, but it certainly saves a lot of steps. On many products, you can do this. With others, the cardboard will rip and it ends up on the ground. It really shouldn’t be too difficult or costly to sell the product with better boxes.

On the other hand, some boxes such as those for OcTTain are difficult to flatten when you’re through with them. On many products, you can just cut the tape holding the bottom together and then it folds up nicely. Others are glued together on the bottom. I end up stomping on these to get them flat.

Gluing the bottoms seems to be overkill. As long as boxes aren’t left out in the rain, just having tape seems more than adequate.

And why is it that some products have to be sold with a booklet the size of a small Bible for each jug? Probably 99 percent of these are never read and end up going in the garbage with the boxes.

Unfortunately, it seems that chemical boxes aren’t allowed for recycling. Wouldn’t it make sense to allow recycling as long as the boxes are clean and free from any contamination?

Now to the jugs themselves. On some products, the seal is in the lid. Just twist off the lid and the product is ready to pour. Unfortunately on most products, you take off the lid and then have to deal with a foil seal adhered to the opening. This is messy and time consuming and you risk getting a chunk of the seal in the spray solution.

Most jugs are punctured on the bottom and emptied into a chem handler. However, if you’re measuring out partial jugs, you need to empty from the top. I wish all products would move away from the foil seal.

I also wish all jugs had a volume calibration on the side and that you could see the level from the outside. Typically, there’s a thin strip of clear plastic down the side of the jug so you can see the level within, but it doesn’t always work with products that are thick and sticky.

While this may not be an easy problem to solve, the other aforementioned issues seem straight forward.

When you choose a crop protection product, the decision isn’t based on the boxes or jugs, but manufacturers could do us a favour with more convenient packaging.

Kevin Hursh is an agricultural journalist, consultant and farmer. He can be reached by e-mail at kevin@hursh.ca.